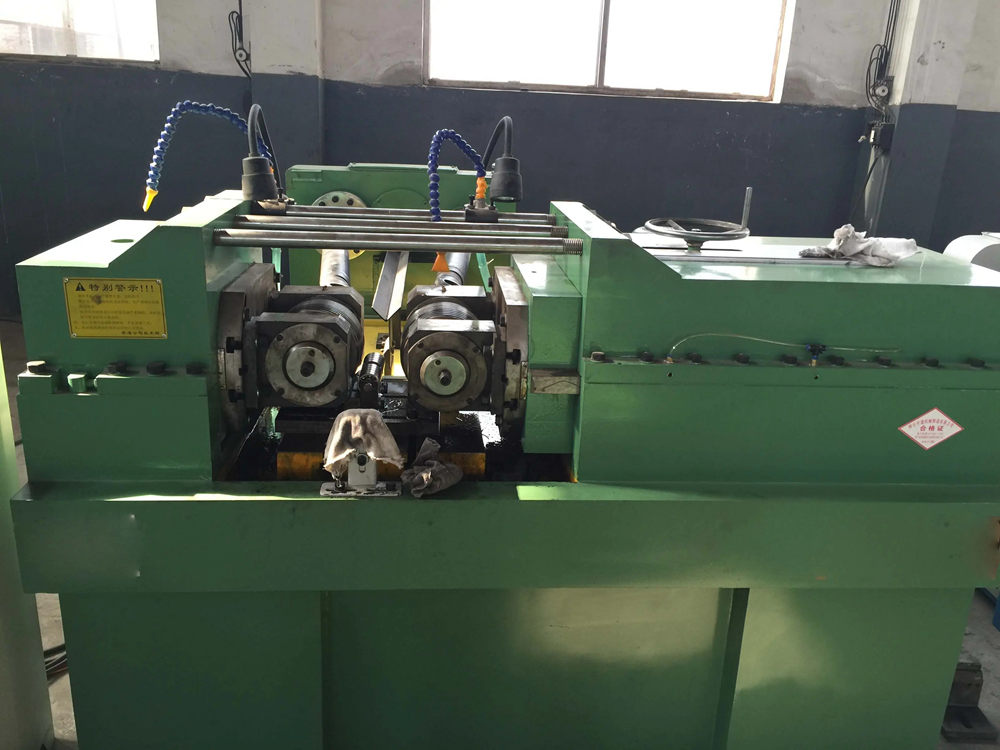

Three Rollers Thread Rolling Machine A Comprehensive Overview

Thread rolling is a widely used manufacturing process for producing threaded fasteners and components with superior mechanical properties. Among various thread rolling methods, the three rollers thread rolling machine stands out for its efficiency and precision. This machine employs a unique mechanism that uses three cylindrical rollers to create threads on a workpiece, enhancing productivity in industrial applications.

The operational principle of a three rollers thread rolling machine is relatively straightforward yet effective. The workpiece, typically made of metal, is inserted between the three rollers, which are arranged in a triangular configuration. As the rollers rotate, they exert pressure on the surface of the workpiece, causing material to flow and form threads. This process is known as cold rolling, as it does not involve any additional heating, which helps retain the material's integrity and strength.

One of the primary advantages of using a three rollers thread rolling machine is the high level of precision it offers. The configuration of the three rollers allows for uniform thread depth and profile, resulting in consistent quality across multiple parts. This precision is crucial in industries such as automotive, aerospace, and machinery manufacturing, where tight tolerances are essential for ensuring the reliability and safety of components.

Moreover, the three rollers design contributes to greater efficiency in production. Compared to traditional single or double roller machines, a three rollers setup reduces production time significantly. This efficiency translates into cost savings for manufacturers, as they can produce more components in a shorter timeframe while maintaining high quality. Additionally, the reduced waste of material in the thread rolling process makes it an environmentally friendly option compared to other manufacturing methods, such as cutting or grinding.

Another notable feature of these machines is their versatility. They can be configured to handle a wide range of thread sizes and profiles, making them suitable for different applications. Whether producing small screws or large bolts, a three rollers thread rolling machine can be adapted to meet specific production requirements.

In conclusion, the three rollers thread rolling machine represents a significant advancement in the manufacturing of threaded components. Its ability to produce high-quality threads efficiently and accurately makes it an indispensable tool in modern manufacturing. As industries continue to evolve and the demand for precision-engineered components grows, the role of thread rolling machines will undoubtedly become even more critical in the quest for innovation and excellence.