The Revolution of Three Wave and Guardrail Making Machines

In the world of manufacturing, efficiency and innovation play significant roles in meeting market demands

. Among the diverse machinery available, the three wave and guardrail making machine stands out for its ability to streamline the production of critical infrastructure components. This machine is not only a marvel of engineering but also a pivotal tool in enhancing road safety.The three wave guardrail is designed to efficiently absorb impact, making it a popular choice for highways and roads. Its unique wave structure dissipates energy from collisions, thereby minimizing damage to vehicles and reducing the risk of injury to passengers. The design also enables the guardrail to flex and return to its original form, enhancing its durability and lifespan. Given these characteristics, the demand for high-quality guardrails continues to rise, prompting advancements in manufacturing technology.

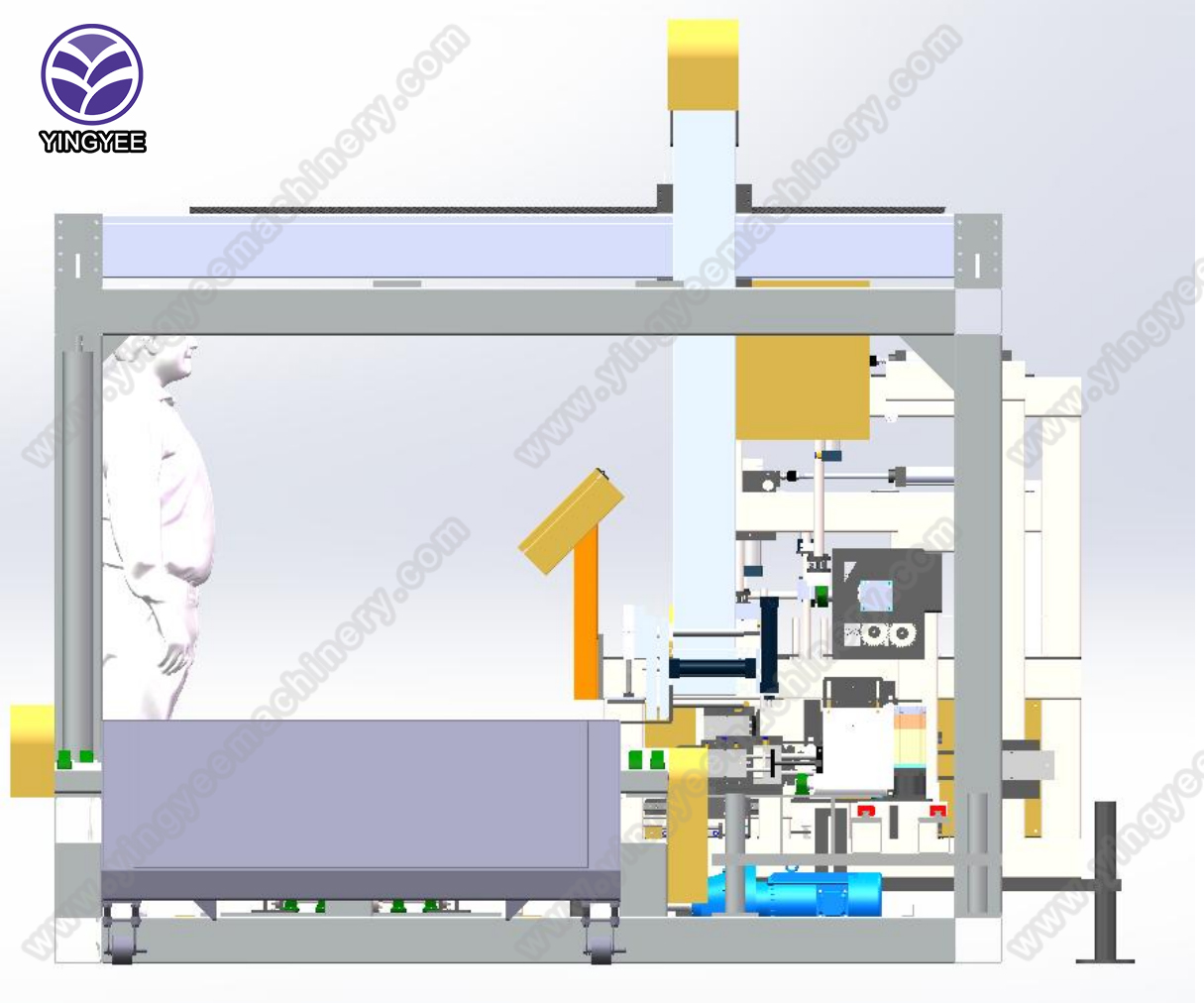

The three wave and guardrail making machine automates the entire production process, promoting efficiency and precision. Traditional methods of guardrail manufacturing involved intensive manual labor, which increased the chances of errors and inconsistency. With the advent of this specialized machinery, the production line can achieve high output rates while maintaining strict quality control standards. This machine is equipped with advanced technologies such as programmable logic controllers (PLCs) and automated cutting systems, which ensure that each component is manufactured to exact specifications.

Moreover, the machine’s versatility allows for the customization of guardrail dimensions and wave patterns, catering to varying requirements across different regions and regulatory standards. Manufacturers can easily adjust the settings on the machine to create guardrails that meet local safety codes, ensuring compliance while optimizing production.

Another significant advantage of the three wave and guardrail making machine is its ability to operate with minimal waste. Traditional manufacturing processes often resulted in excess material being discarded, leading to increased costs and environmental concerns. However, modern machines are designed to maximize the use of raw materials, facilitating a more sustainable approach to production. This not only lowers manufacturing costs but also appeals to environmentally conscious consumers and regulators.

In conclusion, the three wave and guardrail making machine represents a significant advancement in the field of infrastructure manufacturing. By combining efficiency, precision, and sustainability, this machine not only meets the growing demand for guardrails but also enhances road safety. As road networks expand and the need for protective measures increases, the role of innovative machinery in ensuring both quality and safety will become increasingly vital. Embracing such technologies is essential for manufacturers looking to stay competitive in this rapidly evolving industry.