The Evolution and Impact of Thread Form Machine Industries

In the manufacturing landscape, thread form machine industries play a pivotal role in producing fasteners, screws, and various other threaded components essential for numerous applications

. The evolution of these industries has been marked by technological advancements, increased automation, and a growing emphasis on precision and efficiency.Historically, the production of threaded items was a labor-intensive process, relying heavily on manual labor and basic machinery. This began to change in the late 19th and early 20th centuries with the advent of more sophisticated machining tools and techniques. The introduction of computer numerical control (CNC) machines in the 1970s revolutionized the thread form manufacturing process, allowing for greater precision and faster production speeds. CNC technology enables manufacturers to create complex thread forms that meet the evolving requirements of modern engineering.

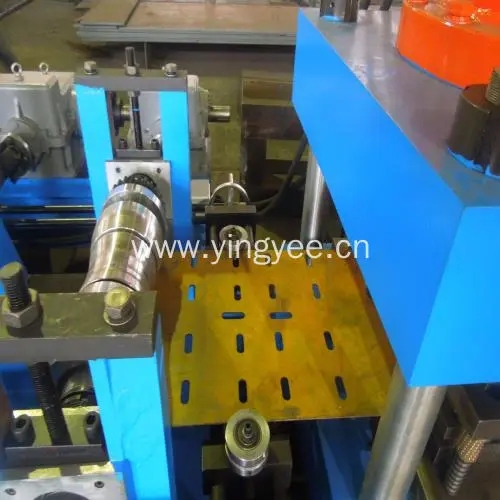

Today, thread form machine industries are characterized by high-tech equipment and automated workflows. The integration of robotics and artificial intelligence (AI) in production lines enhances operational efficiency while minimizing human error. This transition towards smart manufacturing not only boosts productivity but also allows for real-time monitoring and quality control, ensuring that every threaded component meets stringent specifications.

Moreover, the thread form machine industry has a significant impact on various sectors, including automotive, aerospace, construction, and consumer electronics. With the rise of electric vehicles and renewable energy technologies, the demand for specialized threaded components has surged. Manufacturers are now tasked with designing and producing threads that can withstand extreme conditions and load-bearing requirements, further driving innovation in thread forming technologies.

Sustainability is another critical aspect influencing the thread form machine industry. As ecological concerns become increasingly prominent, manufacturers are adopting eco-friendly practices, such as using sustainable materials and optimizing production processes to reduce waste. This shift toward greener manufacturing not only aligns with global sustainability goals but also appeals to a customer base that values corporate responsibility.

In addition to technological advancements, the thread form machine industry faces challenges in workforce development. As automation becomes more prevalent, there is a growing need for skilled technicians who can operate and maintain advanced machinery. Educational institutions and industry organizations are collaborating to create training programs that equip workers with the necessary skills for the future.

In conclusion, the thread form machine industry is experiencing a transformative phase marked by technological innovation, increased demand across various sectors, and a commitment to sustainability. As manufacturers continue to adapt to these changes, the future holds great potential for further advancements in precision manufacturing and the development of new threaded solutions that will support a wide array of applications. The ongoing evolution of this industry will undoubtedly shape the way we approach production, engineering, and sustainability in the years to come.