The T-Bar Ceiling Frame Making Machine An Essential Tool for Modern Construction

The construction industry continually evolves, embracing innovative technologies and equipment to enhance efficiency and productivity. Among these advancements is the T-bar ceiling frame making machine, a vital tool utilized in the installation of suspended ceilings, which are widely used in commercial and residential buildings. This article delves into the features, benefits, and applications of T-bar ceiling frame making machines.

Understanding T-Bar Ceilings

T-bar ceilings, also known as suspended or drop ceilings, comprise a grid system that supports ceiling tiles. This design allows for easy access to wiring and plumbing concealed above the ceiling, making it an ideal choice for offices, schools, hospitals, and various commercial settings. The frames, typically made of lightweight metal, form a grid that holds the ceiling tiles in place while offering versatility in design and aesthetics.

Features of the T-Bar Ceiling Frame Making Machine

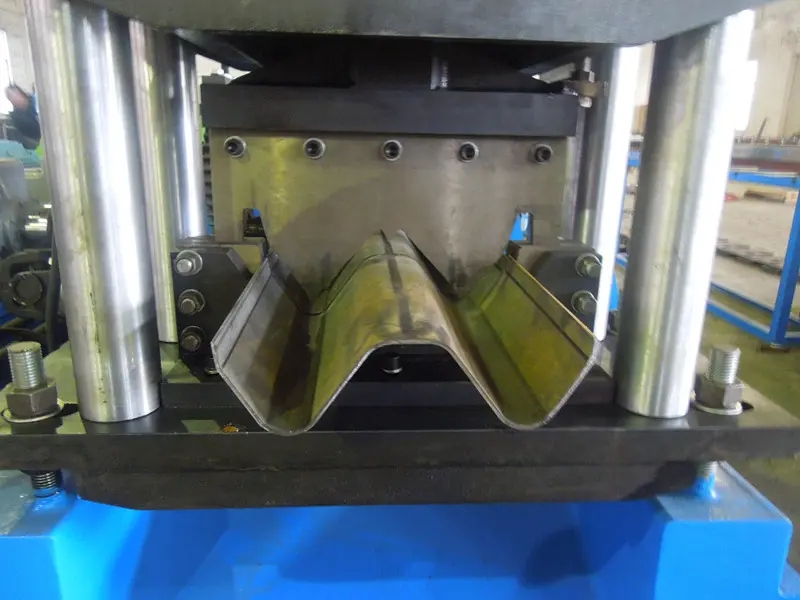

A T-bar ceiling frame making machine is designed to automate the process of fabricating metal frames used in T-bar ceilings. This machine incorporates various advanced features to ensure efficiency and precision

1. Automatic Feeding System The machine is equipped with an automatic feeding mechanism that allows for continuous operation, reducing manual intervention and increasing production capacity.

2. High Precision Cutting Utilizing state-of-the-art cutting technology, the machine delivers precise cuts that ensure uniformity in frame dimensions, crucial for seamless installation.

3. Bending Capability The T-bar frame maker can bend metal strips into required shapes and sizes, accommodating diverse ceiling designs and configurations.

4. Robust Construction Generally built from high-quality materials, these machines offer durability and longevity, suitable for industrial environments.

5. User-Friendly Controls Most machines come with intuitive control panels that allow operators to set parameters efficiently, making them accessible even for those with limited technical expertise.

Benefits of Using a T-Bar Ceiling Frame Making Machine

Implementing a T-bar ceiling frame making machine brings numerous advantages

1. Increased Efficiency By automating the ceiling frame production process, construction companies can significantly reduce labor costs and time, enabling them to complete projects faster.

2. Cost-Effective The initial investment in a T-bar ceiling frame making machine pays off through reduced labor costs and less material wastage, ultimately leading to higher profit margins.

3. Improved Quality With precise cutting and bending capabilities, the quality of the frames produced is superior, resulting in better installations and fewer callbacks due to defects.

4. Flexibility The machine can produce frames of various sizes and styles, allowing businesses to cater to customer preferences and adapt to different project requirements.

5. Reduced Waste Automated production minimizes errors, leading to consistent output and less scrap material, which is beneficial for both the environment and the bottom line.

Applications in Various Settings

T-bar ceiling frame making machines are applicable in diverse sectors, including commercial buildings, educational institutions, healthcare facilities, and even residential projects. Their ability to create tailored designs makes them ideal for environments where aesthetics and functionality are paramount.

Conclusion

The T-bar ceiling frame making machine is transforming the construction landscape, offering enhanced efficiency, quality, and flexibility. As the demand for modern and functional ceiling solutions grows, incorporating such machinery into construction workflows will remain a strategic move for industry players looking to stay competitive. By investing in this technology, construction companies can ensure they meet client needs while maintaining high standards of quality and efficiency.