The Development and Application of T-Bar and T-Grid Making Roll Forming Machines

In the modern construction and manufacturing industries, the demand for products that are not only sturdy but also lightweight has driven the evolution of various fabrication techniques. Among these techniques, roll forming has emerged as a highly efficient method for producing metal profiles, particularly T-bars and T-grids. These components are widely used in construction as structural supports, in ceilings, and in various framework applications. The advent of advanced roll forming machines has significantly enhanced the production process, ensuring high precision and consistency.

Understanding Roll Forming Technology

Roll forming is a continuous bending operation in which a long strip of metal is passed through consecutively arranged rolls at room temperature. This process enables the metal to be bent into desired shapes without the risk of breaking or fracturing. The roll forming machine consists of multiple stations, each equipped with a set of rolls that progressively shape the metal strip into the desired profile.

The efficiency of roll forming lies in its ability to produce long lengths of products with minimal waste. Unlike traditional fabrication methods, which often involve cutting pieces from a larger sheet, roll forming utilizes the material effectively by maintaining the entire strip's integrity throughout the process.

The Significance of T-Bars and T-Grids

T-bars are essential components in various structural applications, providing the necessary support for ceilings, walls, and other architectural features. They are often utilized in the installation of suspended ceiling systems, where the T-bar serves as a support framework for ceiling tiles. T-grids, on the other hand, are used to create a grid-like pattern, allowing for the easy insertion and removal of ceiling tiles while enhancing the aesthetic appeal of interior spaces.

The increasing demand for energy-efficient and lightweight construction materials has led to a rise in the use of T-bars and T-grids. As builders and architects strive to create more sustainable buildings, the importance of these components becomes evident, highlighting the need for efficient production methods.

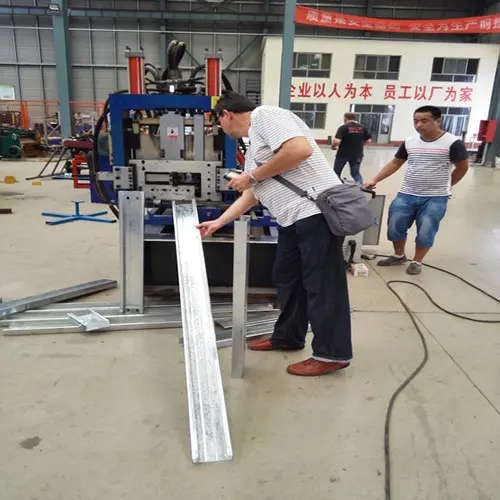

Roll Forming Machines for T-Bar and T-Grid Production

The design and functionality of roll forming machines specifically for T-bar and T-grid manufacturing have evolved significantly. These machines are typically equipped with advanced features, such as programmable controls, high-speed production capabilities, and adjustable roll configurations. This versatility allows manufacturers to produce various sizes and profiles while maintaining high levels of precision.

The first step in the production process involves feeding a metal coil into the machine. The coil is then passed through a series of forming stations that gradually shape it into T-bars or T-grids. The final product is cut to the required length, ensuring uniformity across all pieces. Automation in the machinery reduces labor costs and increases production rates, making it an economically viable option for manufacturers.

Advantages of Using Roll Forming Machines

1. High Efficiency Roll forming machines can produce a large volume of T-bars and T-grids in a short amount of time, significantly reducing lead times for construction projects.

2. Material Savings The continuous nature of the roll forming process minimizes waste, making it an environmentally friendly option.

3. Customizability Manufacturers can easily adjust the machine settings to produce various sizes and designs, catering to specific client needs without extensive retooling.

4. Consistency and Quality The precision of modern roll forming machines ensures that every piece produced adheres to strict quality standards, reducing the likelihood of defects.

Conclusion

The evolution of roll forming technology has revolutionized the production of T-bars and T-grids, vital components in the construction industry. As demands for efficient and sustainable building materials continue to rise, the role of advanced roll forming machines cannot be underestimated. These machines not only enhance productivity but also contribute to the overall quality and performance of construction materials, paving the way for innovative architectural solutions in the future. As industries continue to prioritize efficiency and sustainability, the prominence of T-bar and T-grid making roll forming machines will only grow, solidifying their place in modern manufacturing and construction practices.