The Innovations of T-Bar and T-Grid Roll Forming Machines

In the modern architecture and construction sectors, efficiency and precision are paramount. Among the numerous technologies that have emerged to meet these demands, roll forming machines, specifically for producing T-bars and T-grids, have revolutionized the manufacturing processes. These machines facilitate the creation of essential structural components used extensively in building frameworks and ceilings.

The Innovations of T-Bar and T-Grid Roll Forming Machines

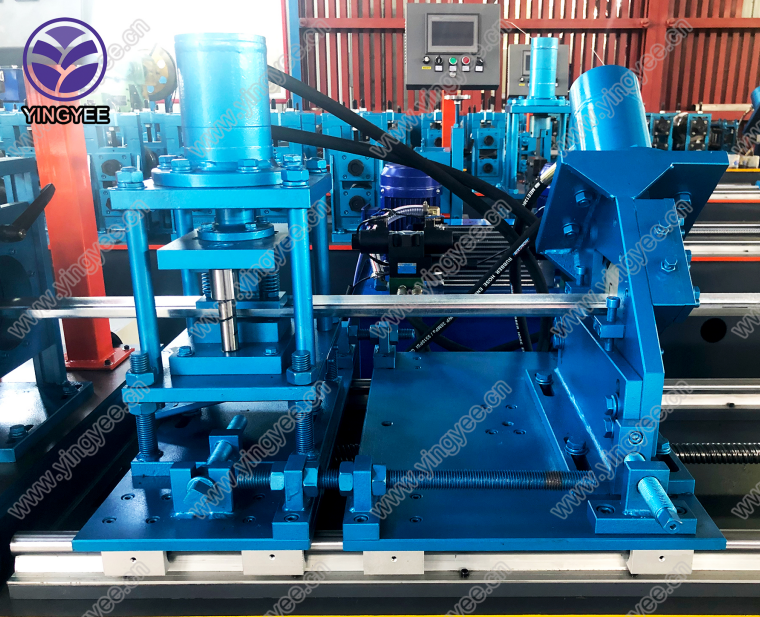

The advanced design of T-bar and T-grid roll forming machines incorporates automation and computer numerical control (CNC) technology. This allows for the consistent production of high-quality products with minimal human intervention. The machine can be programmed to create varying dimensions and profiles according to specific project requirements. As a result, manufacturers can produce custom lengths and shapes, ensuring that each component fits perfectly within the intended application, thereby reducing waste and improving overall productivity.

Efficiency is further enhanced by the machine's ability to operate at high speeds without sacrificing quality. The continuous operation minimizes downtime, allowing manufacturers to meet tight deadlines often found in construction projects. Additionally, the use of high-strength materials in the manufacturing process translates to stronger T-bars and T-grids, ensuring structural integrity and longevity in their applications.

Moreover, the flexibility of these machines is noteworthy. They can handle various materials, including galvanized steel, aluminum, and stainless steel. This versatility enables manufacturers to cater to diverse market needs and adapt to changing material trends, which is vital in a rapidly evolving industry.

Implementing T-bar and T-grid roll forming machines also promotes sustainability. The precise cutting and bending processes minimize scrap material, making them more environmentally friendly compared to traditional manufacturing methods. Furthermore, the durability of the finished products contributes to longer lifespans for building components, which is an essential aspect of sustainable construction practices.

In conclusion, T-bar and T-grid roll forming machines represent a significant advancement in manufacturing technology. With their automated, efficient, and flexible capabilities, they empower manufacturers to produce high-quality structural components essential for modern buildings. As the demand for innovative construction solutions continues to grow, the role of these machines will undoubtedly become more pronounced, shaping the future of the construction industry.