T Ceiling Keel Forming Machine Suppliers An Overview

In the modern construction industry, efficient and precise manufacturing processes are crucial. Among the many tools and machines that facilitate this, the T ceiling keel forming machine plays a significant role. This innovative equipment is specifically designed to produce T-shaped steel components used in ceiling systems, commonly applied in commercial and residential buildings. As the demand for high-quality construction materials continues to rise, suppliers of T ceiling keel forming machines are becoming increasingly vital.

Understanding the T Ceiling Keel Forming Machine

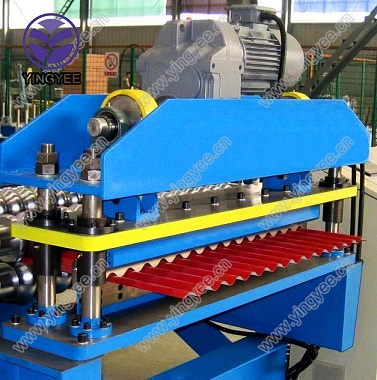

A T ceiling keel forming machine is a specialized piece of equipment that molds metal strips into T-shaped profiles. These profiles serve as supports for suspended ceilings, ensuring durability and stability. The machines are typically equipped with advanced technology that allows for the continuous production of keels, which enhances efficiency and reduces labor costs.

The manufacturing process involves several stages, including metal feeding, shaping, cutting, and punching. A typical T ceiling keel forming machine is designed to handle various metal thicknesses and types, including galvanized steel and aluminum, allowing suppliers to cater to different customer needs. This versatility is one of the key reasons why these machines are in high demand among construction material manufacturers.

The Role of Suppliers

T ceiling keel forming machine suppliers play a crucial role in the construction supply chain. They not only provide the machinery required for production but also offer technical support and maintenance services. This ensures that manufacturers can operate their machines efficiently, minimizing downtime and maximizing output.

Moreover, reputable suppliers often focus on innovation, providing the latest technology in forming machines. Features such as programmable controls, integrated cutting systems, and safety mechanisms enhance operational efficiency and improve product quality. Suppliers who invest in research and development can offer machines that not only meet current industry standards but also anticipate future trends.

Choosing the Right Supplier

When selecting a T ceiling keel forming machine supplier, there are several factors to consider

1. Experience and Reputation Suppliers with a proven track record and positive customer testimonials are often more reliable. 2. Product Range A supplier that offers a variety of machines and customization options can better meet specific needs.

3. Technical Support Reliable technical support and after-sales service are vital for ensuring the smooth operation of the machinery.

4. Quality Assurance Ensure the machines are built to high-quality standards, complying with relevant industry certifications.

5. Pricing and Value While cost is an important factor, it should be balanced with the quality and durability of the equipment being offered.

Conclusion

The demand for T ceiling keel forming machines reflects the ongoing evolution of the construction industry. As building projects become more complex, the need for high-quality, efficient manufacturing equipment is paramount. Choosing the right supplier is essential for manufacturers aiming to thrive in this competitive market. By investing in advanced technologies and maintaining strong relationships with suppliers, the construction industry can ensure the production of reliable and durable ceiling systems that meet the needs of clients worldwide.