The Role of T-Bar and T-Grid in Roll Forming Machinery

In the world of manufacturing, roll forming has established itself as a vital process for producing a variety of structural components. Among the various products created using roll forming techniques, T-bars and T-grids stand out due to their versatility and structural integrity. This article delves into the significance of T-bar and T-grid making roll forming machines, their applications, and the benefits they bring to various industries.

Understanding T-Bars and T-Grids

T-bars are structural steel sections characterized by their T shape, which provides excellent strength-to-weight ratio and superior load-bearing capabilities. They are commonly used in construction and manufacturing for supporting frameworks, providing rigidity to structures, and serving as anchors in various applications. On the other hand, T-grids are often utilized in suspended ceiling systems where they support ceiling tiles and panels, thus enhancing architectural aesthetics while maintaining functionality.

The Roll Forming Process

The roll forming process involves continuously feeding a strip of metal through a series of rolls that gradually shape the material into the desired cross-section. The process is highly efficient, allowing for high-volume production with minimal waste. Roll forming is particularly well-suited for manufacturing T-bars and T-grids because it allows for precise control of the dimensions and mechanical properties of the end product.

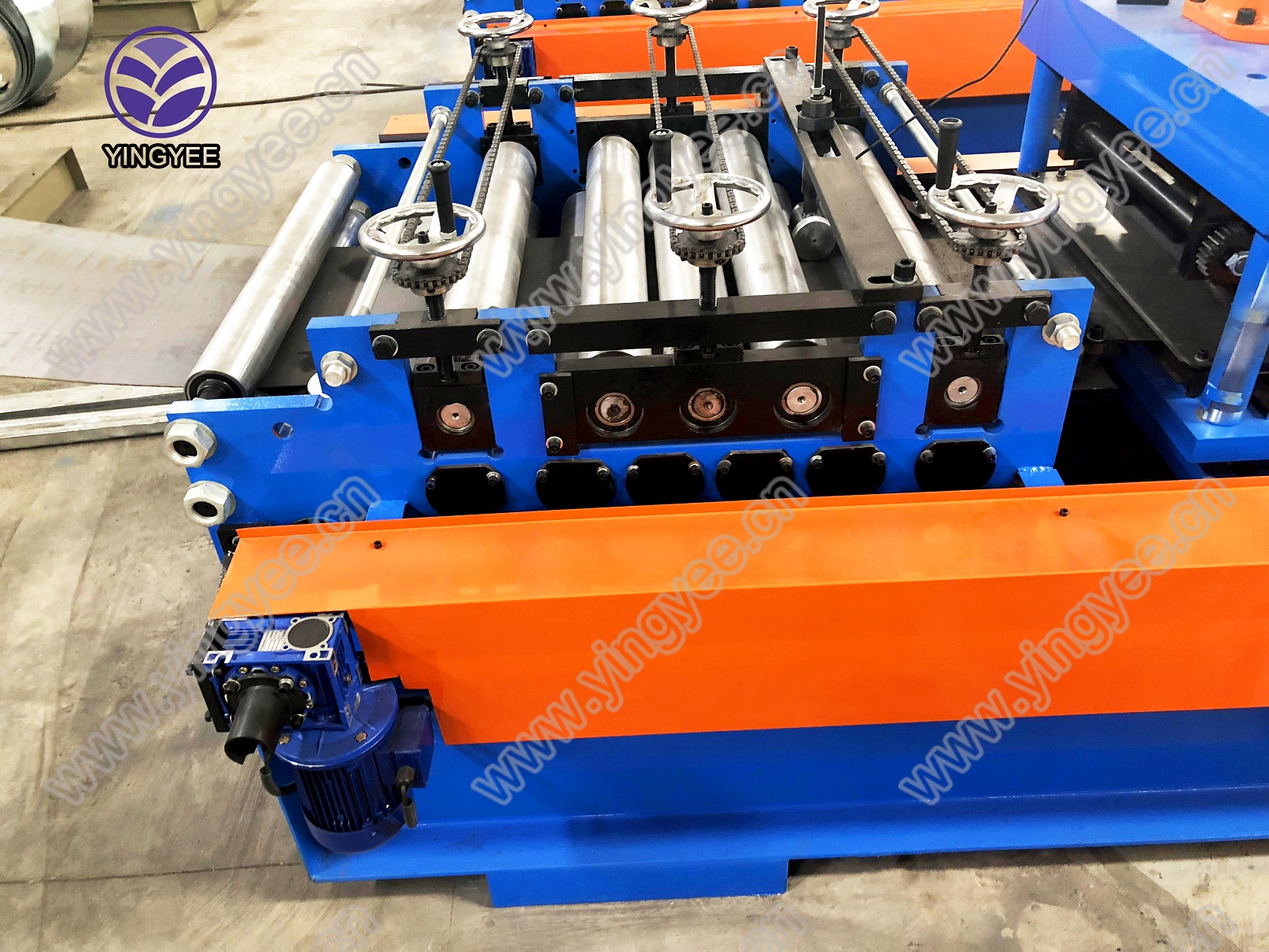

The machine used for roll forming T-bars and T-grids is typically composed of several key components, including a feeding system, forming stations, and a cutting mechanism. As the metal strip passes through progressing forming stations, it is gradually shaped into the final T-bar or T-grid profile. The cutting mechanism then demands precision to ensure accurate lengths, vital for their structural performance in application.

Applications in Industries

T-bars and T-grids produced by roll forming machines have numerous applications across various sectors, including construction, automotive, aerospace, and retail. In construction, T-bars are utilized in structural frameworks and support systems, ensuring buildings can withstand environmental stresses. T-grids facilitate efficient ceiling installations, allowing for easy integration of lighting and HVAC systems, contributing to smarter and more adaptable building designs.

In the automotive industry, these components may be used as structural reinforcements, while in aerospace, their lightweight properties and strength are indispensable for creating aircraft components. Retail fixtures, like display racks or shelving systems, also benefit from T-bars and T-grids due to their ability to efficiently manage weight distribution.

Benefits of Roll Forming T-Bars and T-Grids

The roll forming method boasts several advantages when it comes to producing T-bars and T-grids. Firstly, the ability to create long lengths without the need for joints results in stronger and more stable structural components. Additionally, the process offers excellent repeatability and precision, leading to minimal variation in product dimensions.

Moreover, roll forming is highly adaptable; it can work with various materials, including steel and aluminum, allowing manufacturers to select the most appropriate material for their specific application. Cost-effectiveness is another significant benefit, as the high production rates and low material waste contribute to reduced operational costs.

Conclusion

In summary, T-bar and T-grid making roll forming machines play a crucial role in modern manufacturing by providing efficient and precise production methods for essential structural components. Their wide-ranging applications across multiple industries highlight the significance of these products, while the benefits of roll forming technology ensure they remain a vital aspect of contemporary engineering and construction practices. As industries continue to evolve, the demand for innovative and reliable structural solutions like T-bars and T-grids will only grow, solidifying the importance of roll forming in the future.