The Swing Shearing Machine An Overview of Its Importance and Manufacturing

In the realm of metalworking and fabrication, the swing shearing machine has emerged as a pivotal tool for industries that require precise cutting of sheet materials. This equipment is crucial in numerous sectors, including automotive, aerospace, and construction, where the demand for precision and efficiency is paramount. Understanding the significance of the swing shearing machine and the intricacies of its manufacturing process helps appreciate its role in modern industry.

What is a Swing Shearing Machine?

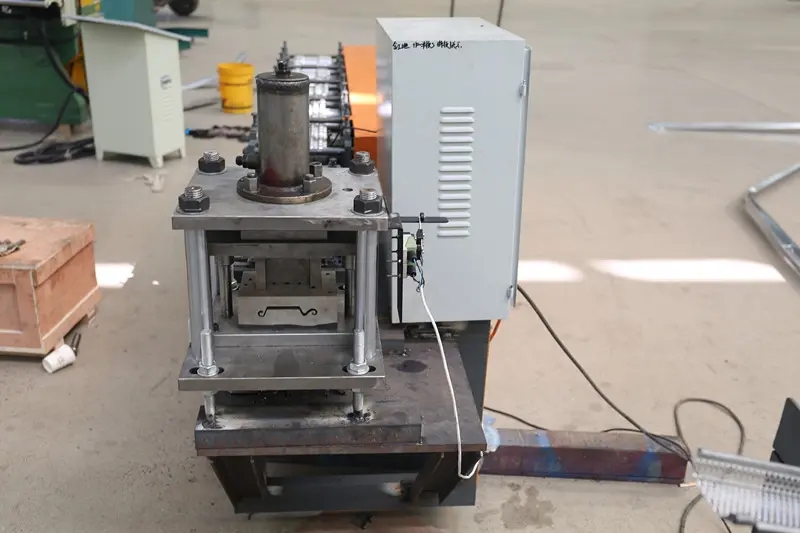

A swing shearing machine is designed to cut metal sheets with exceptional accuracy. It typically comprises a robust frame, a cutting blade, and a work table. The mechanism operates on the principle of a swinging motion, where the blade moves in a pivoting action, allowing for clean cuts along the desired lines. This design is particularly advantageous for thicker materials, as it reduces the strain on the machine and ensures a smoother cut.

The shearing machine generally operates with a hydraulic system, which enables it to exert significant force during the cutting process. This hydraulic functionality helps to achieve consistent results, minimizing the risk of deformities in the finished product. Additionally, the setup allows for easy adjustments in blade height and angle, accommodating various material thicknesses and types.

Importance of Swing Shearing Machines in Industries

The swing shearing machine is invaluable in various manufacturing domains due to its versatility and efficiency. In the automotive industry, for instance, precision cutting of metal sheets is essential for producing body panels, frames, and other components. A reliable shearing machine can significantly improve production timelines while maintaining high-quality standards.

Moreover, in the construction sector, these machines facilitate the quick and efficient processing of materials such as steel and aluminum for structural applications. The accuracy of cuts enhances the overall integrity of structures and allows for seamless integration of components during assembly.

Manufacturing Process of Swing Shearing Machines

Creating a swing shearing machine involves meticulous attention to detail and an understanding of engineering principles. The manufacturing process typically commences with the design phase, where engineers create detailed blueprints that outline specifications, dimensions, and materials. Advanced computer-aided design (CAD) software plays a crucial role in this phase, allowing manufacturers to visualize the final product and make necessary adjustments.

Once the design is finalized, the production phase begins. This includes sourcing high-quality materials, such as hardened steel for the cutting blade and durable metals for the machine frame. Precision machining processes, including cutting, welding, and assembly, are employed to shape each component accurately. Quality control is paramount throughout this phase; machines undergo rigorous testing to ensure they meet industry standards and performance requirements.

Finally, once assembled, the finished swing shearing machines are subjected to additional tests to verify their operational efficiency and safety. Once they pass all inspections, they are ready for distribution to various industries, where they will find their essential roles.

Conclusion

The swing shearing machine represents a blend of innovation and practicality in the metalworking industry. Its design and function cater to the diverse needs of manufacturing processes, ensuring that businesses can operate efficiently while maintaining the highest standards of quality. As industries continue to evolve, the demand for such cutting-edge machinery will only increase, underscoring the importance of swing shearing machines in modern production environments. Their ability to deliver precision cuts in various materials makes them indispensable for numerous applications, reaffirming their value in contemporary manufacturing processes.