Investing in a suspended ceiling T grid forming machine can revolutionize your construction projects by offering precision, efficiency, and durability. As an industry leader with over 20 years of experience in advanced machinery, I can attest to the incredible value these machines bring to manufacturing processes.

Suspended ceiling T grid forming machines are engineered to meticulously craft metal grids that support ceiling tiles in commercial and residential buildings. This niche but essential component of interior architecture demands machines that produce high-quality, consistent output. Leveraging these machines maximizes production rates while minimizing error margins, ultimately enhancing the overall project quality.

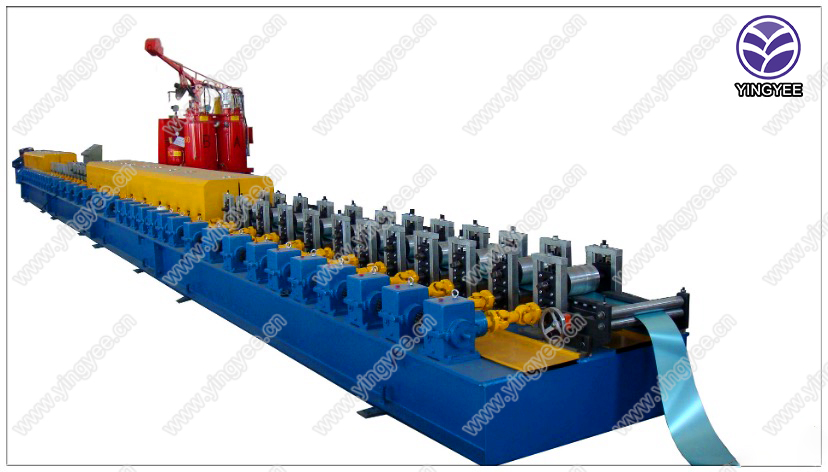

One of the remarkable features of a high-grade T grid forming machine is its automated system, which ensures precision in each grid’s dimensions. These machines are equipped with a series of rollers that systematically shape and cut metal strips into T-shaped profiles. Automation reduces human error, increases the speed of production, and ensures that every piece meets stringent industry standards. This high precision is particularly crucial in large projects where consistency is key to fitting grids perfectly across vast spaces.

From an expertise standpoint, understanding the mechanics behind these machines can significantly enhance their utility. The machines are constructed with top-tier materials designed to withstand high volumes of operation without compromising on accuracy or speed. The rollers and cutting mechanisms are made of durable alloys that resist wear and tear, ensuring longevity and reduced maintenance costs. It is crucial to select machines from manufacturers who prioritize durability and innovation, as these qualities contribute to the machine's operational trustworthiness over time.

In terms of authoritativeness, several industry guidelines exist to certify the machines' quality. Certification from reputable bodies such as CE, ISO9001, among others, signifies compliance with international manufacturing standards. These certifications are testimonies to the machines' quality and efficiency. When choosing a T grid forming machine, prioritizing those that carry recognized certifications assures adherence to safety and production standards, thus instilling confidence in your purchase decision.

suspended ceiling t grid forming machine

Trustworthiness in machinery investment also comes from comprehensive customer service and support. Reliable suppliers provide detailed installation guides, operator training, and technical support to ensure that the machines function optimally and any operational challenges are swiftly addressed. This service level affirms the manufacturer’s commitment to quality and customer satisfaction, a critical component of building trust with machine users.

The versatility of the suspended ceiling T grid forming machine is another advantage, enabling it to handle a variety of metal types and thicknesses, and producing different T grid patterns tailored to specific project requirements. This adaptability allows for project diversification, equipping manufacturers to cater to a broader market with unique and customized client needs. This kind of flexibility not only enhances service offering but also broadens business potential by reaching out to different segments of the construction industry.

For professionals eager to improve their operational efficiency, integrating a suspended ceiling T grid forming machine into your production suite is a strategic move. The machine significantly boosts output while maintaining exceptional quality standards, positioning businesses to deliver superior services within competitive timelines. Additionally, it contributes to cost efficiency by reducing waste, streamlining labor requirements, and minimizing downtime due to maintenance or repairs.

In conclusion, a suspended ceiling T grid forming machine is an indispensable asset for modern construction and architecture enterprises seeking excellence in ceiling installation. Its combination of precision, durability, and versatility supports achieving high production and craftsmanship standards. Being informed and discerning in your choice of machine can enhance your business operations, elevate service delivery, and establish your reputation as an industry authority.