The Evolution and Importance of Supermarket Shelf Back Panel Roll Forming Machines

In the modern retail landscape, the presentation of products plays a crucial role in attracting customers and driving sales. One of the key elements that contribute to effective product display in supermarkets is the shelving system. Among the various components that make up these shelves, the back panels serve not only a structural purpose but also enhance the aesthetics of product presentations. To meet the growing demand for high-quality, durable, and visually appealing back panels, many manufacturers have turned to advanced technology—specifically, the supermarket shelf back panel roll forming machine.

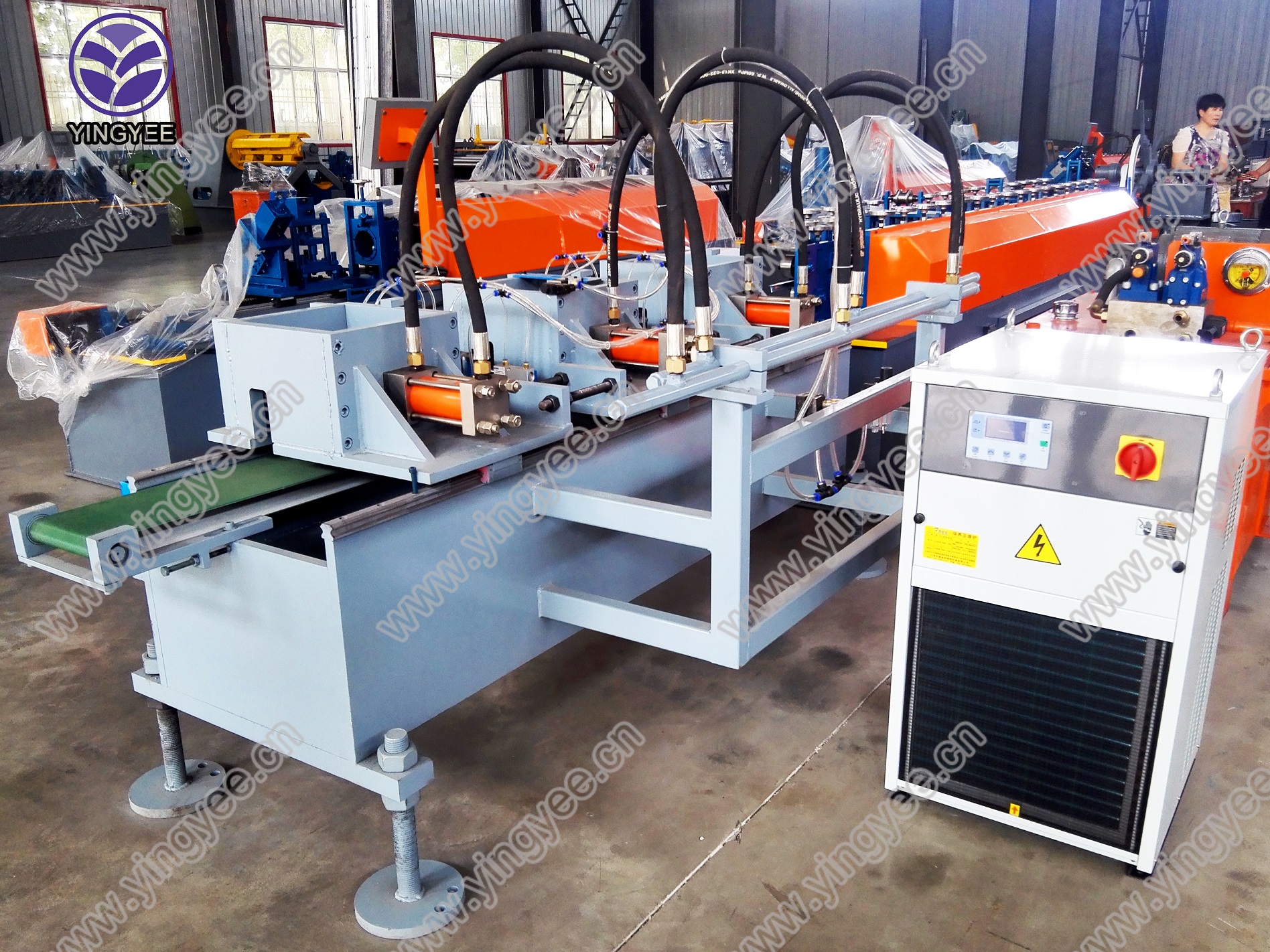

What is a Roll Forming Machine?

A roll forming machine is a type of equipment used to create long sections of metal by continuously bending the material over a series of rollers. The process converts flat metal sheets into a defined shape or profile, which can then be cut to specific lengths. Roll forming is advantageous for producing large quantities of consistent products with tight tolerances. By utilizing this technology, manufacturers can efficiently produce back panels that meet the rigorous demands of the supermarket industry.

The Role of Back Panels in Supermarkets

Back panels serve multiple functions in a supermarket setting. Firstly, they provide structural support to the shelving units, ensuring stability and safety for both the products displayed and the customers browsing the aisles. Secondly, they offer a backdrop to products that enhances visibility and draws consumer attention. A well-designed back panel can create an engaging retail environment, encouraging customers to explore different products.

The material used for back panels is essential; it must be strong, lightweight, and capable of withstanding the daily wear and tear of a busy supermarket. Common materials include galvanized steel, aluminum, and other durable composites. This is where the role of roll forming machines becomes pivotal, as they can tailor the back panels' thickness, size, and finish to suit specific retail needs.

Advantages of Using Roll Forming Machines

1. Consistency and Precision One of the primary benefits of using roll forming technology is its ability to produce high volumes of back panels with uniform quality. This precision ensures that all panels fit seamlessly into the shelving systems, facilitating easy installation and reducing maintenance issues.

2. Cost-Effectiveness Roll forming minimizes waste by producing a substantial amount of material from a single sheet of metal, making it an economical choice for manufacturers. The process also requires less labor compared to other manufacturing methods, which further drives down costs.

3. Customization Manufacturers can easily adjust the roll forming process to create panels of various designs, profiles, and finishes. This flexibility allows for tailored solutions that meet specific supermarket branding and aesthetic requirements.

4. Durability The materials typically used in roll forming are resistant to corrosion, rust, and other environmental factors. This guarantees that back panels are not only visually appealing but also long-lasting, contributing to the supermarkets' sustainability goals.

The Future of Roll Forming Machines in Retail

As retail continues to evolve, so does the technology that supports it. The supermarket shelf back panel roll forming machine is poised to undergo further advancements, integrating innovative features such as automation, smart manufacturing, and enhanced energy efficiency. The rise of e-commerce and shifting consumer behaviors could also influence how supermarkets design their shelves, leading to more creative and adaptive shelving solutions.

Furthermore, as sustainability becomes a more significant focus for retailers, the development of eco-friendly materials and processes in roll forming will likely gain prominence. Manufacturers must stay ahead of the curve by adopting green technologies and practices that resonate with environmentally conscious consumers.

Conclusion

The supermarket shelf back panel roll forming machine is an essential piece of equipment in the retail industry, driving efficiency, quality, and innovation in product displays. As consumer expectations continue to rise, the importance of well-designed shelving solutions will only grow. By leveraging advanced roll forming technology, manufacturers can ensure that supermarkets remain an inviting place for shoppers, fostering engagement and ultimately enhancing sales. The future of retail depends on such innovations that balance functionality, aesthetics, and sustainability in the shopping experience.