The Evolution and Impact of Stud Making Machines

In the landscape of manufacturing, stud making machines represent an essential yet often overlooked segment that plays a crucial role in various industries. These machines are specialized tools designed for producing studs, which are essential fasteners utilized in construction, automotive, aerospace, and numerous other applications. The technology behind stud making machines has evolved significantly over the years, driven by the demands for efficiency, precision, and versatility.

A stud is generally defined as a cylindrical rod with threads on both ends. It serves as a connector holding two parts together, providing stability and strength. The design of stud making machines has evolved from manual operations in small workshops to sophisticated fully automated systems capable of producing thousands of pieces in a matter of hours. This development can be attributed to advancements in technology, material science, and the growing demand for reliable fastening solutions in engineering.

Modern stud making machines are equipped with CNC (Computer Numerical Control) technology, ensuring high precision and repeatability in the manufacturing process. This technology allows for the automatic adjustment of machine settings based on the specific requirements of the studs being produced. As a result, manufacturers can produce a diverse range of stud sizes and thread configurations without extensive downtime for re-tooling, significantly enhancing productivity.

Moreover, contemporary machines are designed with user-friendly interfaces, allowing operators to program complex manufacturing processes with ease. This accessibility enables even small-scale manufacturers to invest in automated machinery without the need for extensive technical training. Consequently, there is an uptick in small businesses entering the stud manufacturing market, fostering healthy competition and innovation.

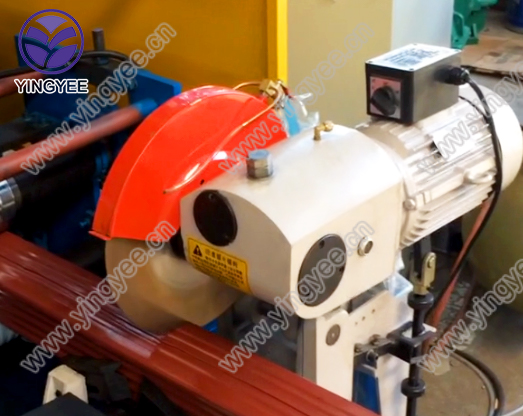

One of the remarkable features of modern stud making machines is their ability to perform multiple operations in one cycle. For instance, a single machine can handle processes such as cutting, threading, and even surface treatment. This capability streamlines production lines and reduces the overall manufacturing footprint, which is a critical aspect in today’s environmentally-conscious market. The reduction in waste and by-products not only minimizes operational costs but also aligns manufacturing practices with sustainable development goals.

In terms of material usage, advancements in metallurgy have contributed to the production of stronger and lighter studs. Modern stud making machines are capable of working with various materials, including stainless steel, carbon steel, and even special alloys, which significantly expand their application range. The ability to produce corrosion-resistant and thermally stable studs ensures reliability in critical applications—such as automotive engines and aerospace components.

The rise of automation and digital monitoring has also introduced new possibilities for process optimization. Many stud making machines now come equipped with sensors that provide real-time feedback on production metrics, enabling manufacturers to quickly identify inefficiencies and make informed decisions to enhance performance. Predictive maintenance features can further reduce downtime, allowing for uninterrupted production and higher profitability.

As industries continue to evolve, the stud making machine will undoubtedly adapt to new challenges and innovations. From meeting tighter tolerances to accommodating novel materials and designs, these machines will play a vital role in shaping the future of manufacturing. By investing in technologically advanced stud making machines, companies can enhance their capabilities, ensuring they remain competitive in an ever-changing market.

In conclusion, stud making machines are far more than simple industrial tools; they are a reflection of the synergy between engineering and innovation. As manufacturers embrace the benefits of automation and precision engineering, the significance of these machines in global production systems cannot be understated. The evolution of stud making technology exemplifies how advancements in manufacturing can lead to improved efficiency and sustainability across various sectors.