The Importance of Stud Forming Machines in Modern Manufacturing

In the ever-evolving landscape of manufacturing, the demand for precision and efficiency continues to rise. Among the many tools that have emerged to meet these needs, the stud forming machine has gained significant attention. These machines play a crucial role in producing high-quality fasteners, such as studs and screws, which are essential components in a wide variety of industries including automotive, aerospace, construction, and electronics. In this article, we will explore the functionality, advantages, and significance of stud forming machines in modern manufacturing processes.

Understanding Stud Forming Machines

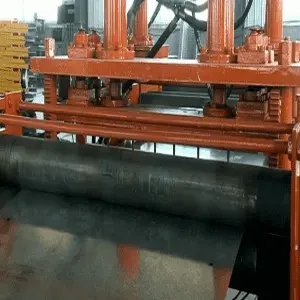

Stud forming machines are specialized pieces of machinery designed to create fasteners from metal wire. The process typically involves feeding a coil of wire into the machine, where it undergoes several stages of forming, cutting, and sometimes heat treatment to produce the final stud or fastener. The capabilities of these machines can vary widely, but many include features such as automatic feeding systems, programmable controls, and advanced tooling that allow for the production of complex geometric shapes and variations in size.

Key Advantages of Stud Forming Machines

1. High Efficiency and Throughput One of the primary advantages of stud forming machines is their ability to produce fasteners at a rapid pace. Modern machines can create hundreds, if not thousands, of studs per hour, significantly reducing production times compared to traditional methods. This high throughput is essential for meeting the demands of industries where large volumes of components are required.

2. Precision and Consistency The automated nature of stud forming machines ensures that each fastener produced is nearly identical in size and shape. This level of precision is critical in applications where even minor discrepancies can lead to product failure or safety issues. Moreover, advancements in technology allow for enhanced accuracy, with some machines equipped with sensors and feedback systems that monitor the forming process in real-time.

3. Cost-Effectiveness Although the initial investment in stud forming machines can be substantial, the long-term savings they provide often outweigh the costs. By minimizing waste and optimizing material usage, manufacturers can reduce production costs. Additionally, the speed and efficiency of these machines lead to lower labor costs, as fewer operators are needed to manage production.

4. Versatility Stud forming machines can be adapted to produce a wide range of fasteners, including various lengths, diameters, and thread types. This versatility allows manufacturers to quickly switch production lines based on customer needs or market demands, increasing their competitiveness in a fast-paced market.

The Role of Stud Forming Machines in Various Industries

Stud forming machines are integral to several industry sectors. In the automotive industry, for example, they are used to produce the bolts and screws necessary for vehicle assembly. Similarly, in the aerospace sector, precision-engineered fasteners are critical for maintaining safety standards in aircraft manufacturing.

Construction companies also rely heavily on these machines to provide the fasteners needed for structural integrity in buildings and infrastructure projects. Furthermore, the electronics industry utilizes studs and screws in the assembly of various devices, from smartphones to computers, highlighting the importance of these machines in everyday products.

Future Trends and Innovations

The evolution of stud forming machines is far from over. As manufacturers continue to seek ways to improve efficiency and reduce costs, advancements in technology will drive innovations in this field. The integration of smart manufacturing concepts, such as IoT (Internet of Things) and AI (Artificial Intelligence), is expected to enhance the capabilities of stud forming machines. These technologies can enable predictive maintenance, improve process monitoring, and allow for more sophisticated process optimization.

Moreover, as sustainability becomes a focal point in manufacturing, future stud forming machines may increasingly incorporate eco-friendly practices, such as using recycled materials and minimizing energy consumption.

Conclusion

In conclusion, stud forming machines represent a vital component of modern manufacturing, providing efficiency, accuracy, and versatility in the production of fasteners that are essential across numerous industries. As technology continues to advance, these machines will likely become even more integrated into the manufacturing process, driving further innovations and improvements. Understanding their significance and capabilities is essential for manufacturers looking to stay competitive and responsive in a dynamic market.