Stud and Track Machine Manual Changes by Spacer for Size Adjustment

In today's rapidly evolving industrial landscape, the need for flexible equipment that can adapt to various operational demands is crucial. One such piece of machinery is the stud and track machine, which is primarily used in construction and manufacturing processes to assemble components efficiently. One of the significant challenges faced by operators of these machines is the need to change sizes based on different project specifications. Implementing a manual spacer system can significantly simplify this process, allowing for swift adjustments while ensuring precision and reliability.

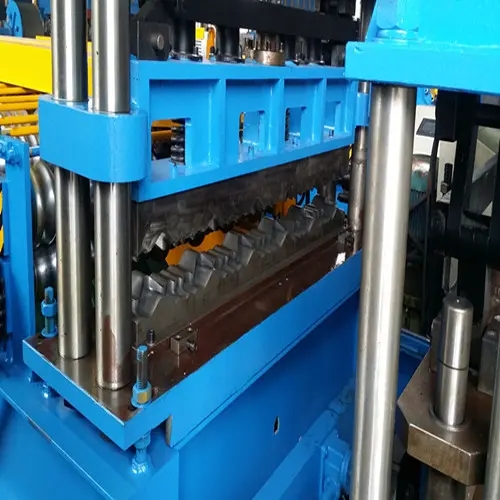

The stud and track machine operates by attaching studs to tracks, forming a stable framework that can support drywall, insulation, and other construction materials. Given the diverse nature of construction projects, the required stud and track sizes can vary greatly. Therefore, it becomes essential for operators to adjust their machines accordingly. This is where the manual control of spacers comes into play.

Manual spacers are designed to provide a quick and efficient method for size adjustments. By incorporating adjustable spacers into the stud and track machine's design, operators can easily alter the distance between the studs, enabling the assembly of different track sizes without the need to replace entire components. This not only saves time but also reduces the costs associated with purchasing multiple machinery setups for various sizes.

The first step in utilizing manual spacers effectively involves a thorough understanding of the machine's configuration. Operators should familiarize themselves with the machine's components and how spacers can be integrated into the system. Clear documentation and training sessions can equip workers with the knowledge they need to make changes confidently and correctly.

Once operators have a solid grasp of the machine's working parts, they can begin the process of adjusting size configurations. This typically involves loosening specific bolts or clamps that secure the existing spacers in place. Using a wrench or other tools, operators can insert additional spacers or remove them altogether to achieve the desired distance between studs. After making these adjustments, it is crucial to tighten all connections securely to maintain the integrity of the machine during operation.

While manual adjustment of spacers might seem straightforward, attention to detail is vital to ensure accurate measurements. Operators should have a reliable measurement tool handy to verify that the spacing is correct before proceeding with the assembly process. Moreover, regular checks and calibrations of the machine are advised to keep it running at optimal performance.

Furthermore, integrating best practices for maintenance can enhance the longevity and reliability of the stud and track machine. Keeping a log of adjustments and the conditions under which the machine operates can help identify patterns or recurring issues that might arise due to improper size changes.

In conclusion, manually adjusting spacer sizes on a stud and track machine offers a practical solution for accommodating varying project requirements in the construction industry. By allowing quick modifications, operators can efficiently respond to changing demands while maintaining productivity. As industries continue to embrace automation and advanced technologies, the significance of adaptable machinery such as the stud and track machine becomes increasingly apparent. Emphasizing training, careful adjustment processes, and maintenance ensures that operations run smoothly and effectively, meeting the challenges of a dynamic work environment.