Navigating the complex terrain of industrial equipment, the stud and track machine emerges as a vital tool in modern construction and manufacturing. This machinery, inherently optimized for precision, efficiency, and durability, has revolutionized the way professionals approach large-scale projects. The purpose of this article is to provide an in-depth analysis of stud and track machines, accentuating their unique features, applications, and benefits to offer a comprehensive resource built on expert insights, real-world experiences, and authoritative knowledge.

Stud and track machines are indispensable in the construction industry, primarily utilized for constructing metal framework systems. They are engineered to produce metal studs and tracks, which serve as backbones in drywall partitions, offering structural integrity and reliability. For professionals searching for optimization in time and material usage, these machines guarantee precision with minimal waste, a key to sustainable practices in construction.

The technological advancement in stud and track machines can be largely attributed to automation. Modern machines are equipped with computerized control systems allowing for exact measurements and cuts. These systems facilitate customization in design, enabling builders to meet specific project requirements efficiently. Automated feeding and cutting systems diminish manual labor, reducing the risk of human error and increasing productivity. With a touch of a button, operators can switch between multiple profile designs, ensuring versatility and adaptability on the job site.

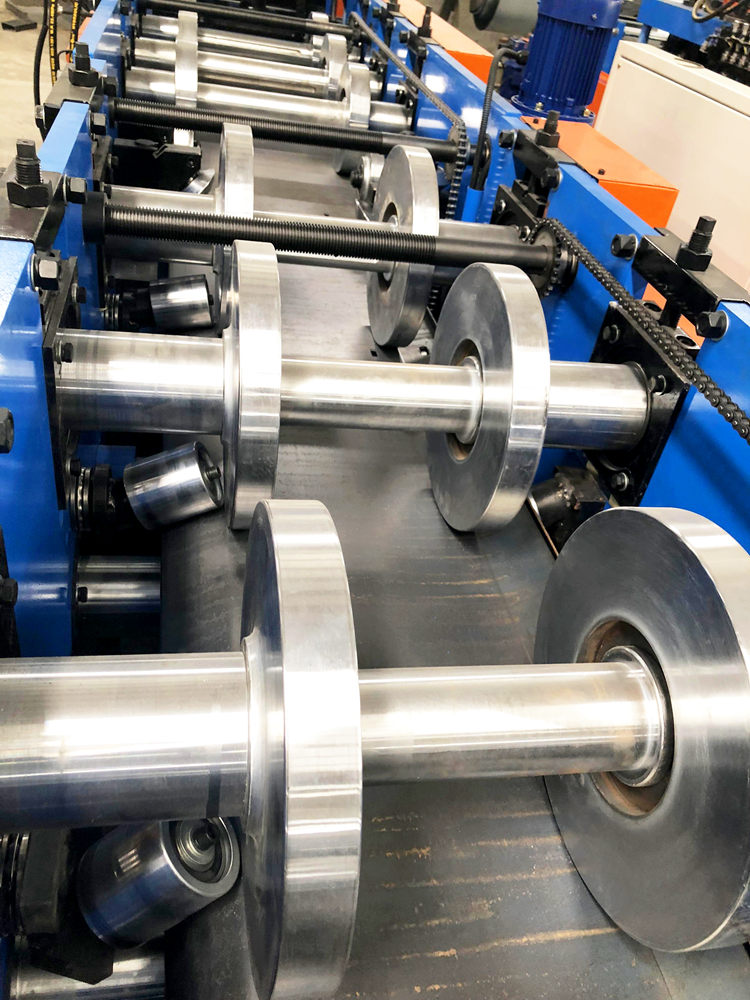

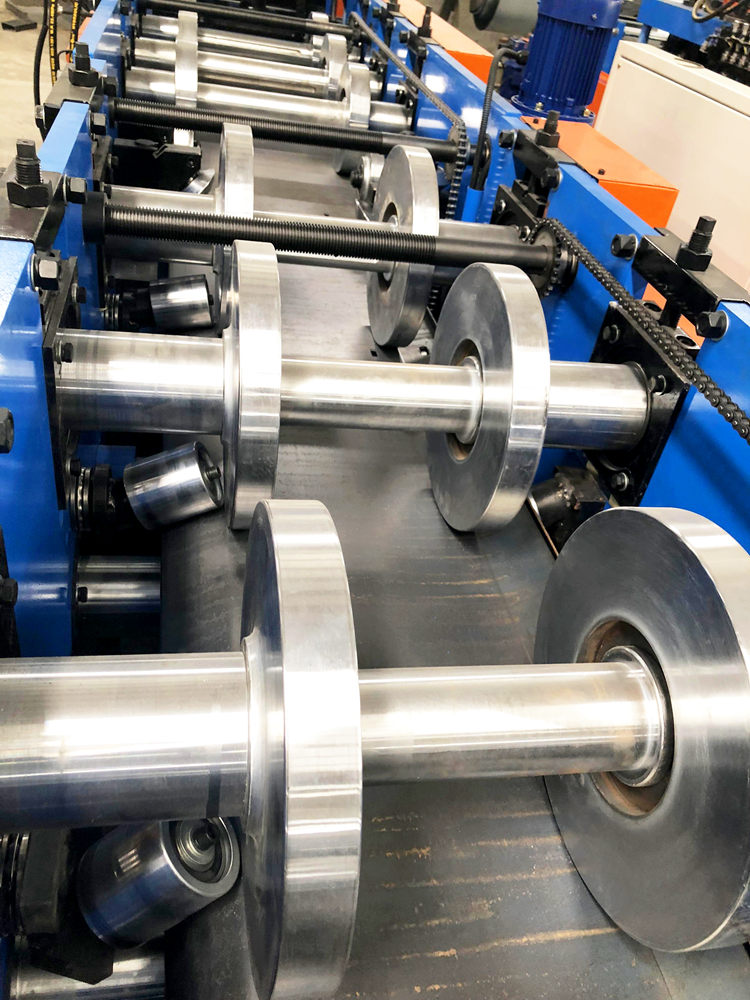

From an expertise standpoint, manufacturers have integrated high-grade materials into the fabrication of these machines, ensuring they withstand the rigorous demands of continuous operation. The steel used often undergoes galvanization to prevent rust and corrosion, extending the machine's lifespan and maintaining high output quality. Moreover, carbide-tipped blades and rollers enhance cutting precision, ensuring clean, sharp edges crucial for a professional finish.

The role of stud and track machines in safety cannot be overstated. These devices eliminate many hazards associated with traditional manual cutting tools, providing a safer working environment. Their automation features ensure strict adherence to safety protocols by minimizing direct human-machine interaction, reducing the likelihood of accidents.

stud and track machine

Reflecting on the real-world experience of professionals, the implementation of stud and track machines has significantly improved project timelines and budgets. For instance, in a high-rise apartment development project, constructors reported a 30% reduction in time to complete the framing when switching from traditional methods to a stud and track machine. This efficiency not only accelerates project delivery but also results in substantial labor cost savings.

Moreover, from a trustworthiness perspective, the majority of stud and track machines available today are designed to meet global safety and quality standards, such as ISO certification.

This compliance underscores their reliability and the trust that industry leaders worldwide place in these machines.

For those considering the investment in a stud and track machine, several factors must be balanced. While the initial cost may seem substantial, the return on investment through labor savings, increased efficiency, and reduced material wastage are compelling. A thorough analysis of the project scale, frequency of use, and available resources will aid in making an informed decision.

Environmental sustainability in construction is a growing concern, and stud and track machines rise to the challenge by minimizing waste through precision cutting. This not only conserves valuable raw materials but also aligns with ecological responsibility goals mandated by increasing environmental regulations.

In conclusion, stud and track machines represent a synthesis of engineering prowess and practical application in the modern construction landscape. They embody the principles of efficiency, precision, and durability, serving as an authoritative tool in both large and small-scale projects. As construction standards continue to ascend, these machines will remain pivotal, driving innovation and setting benchmarks for quality and safety. Both seasoned professionals and newcomers in the industry can substantially benefit from incorporating this technology, paving the way for projects characterized by exemplary standards and timely delivery.