Understanding the stud and track frame forming machine is essential for anyone engaged in building construction and steel framing. These machines play a pivotal role in the fabrication of frames used in drywall construction, providing precision and efficiency that manual methods simply cannot match. With advancements in technology, the modern stud and track frame forming machines have revolutionized the construction industry by enhancing both productivity and quality.

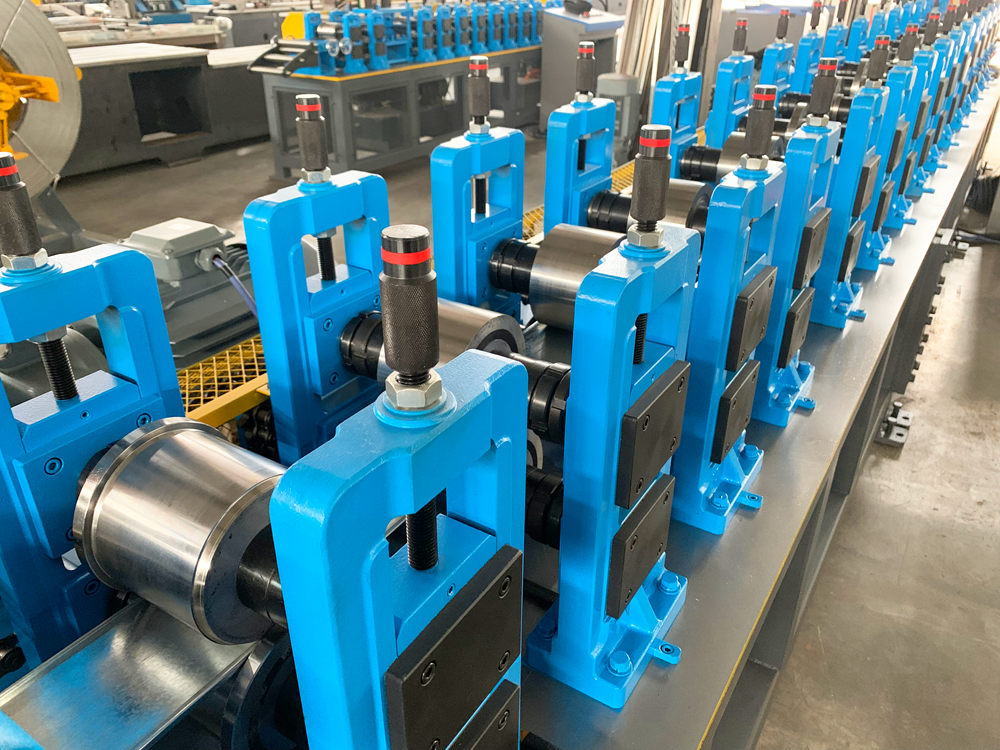

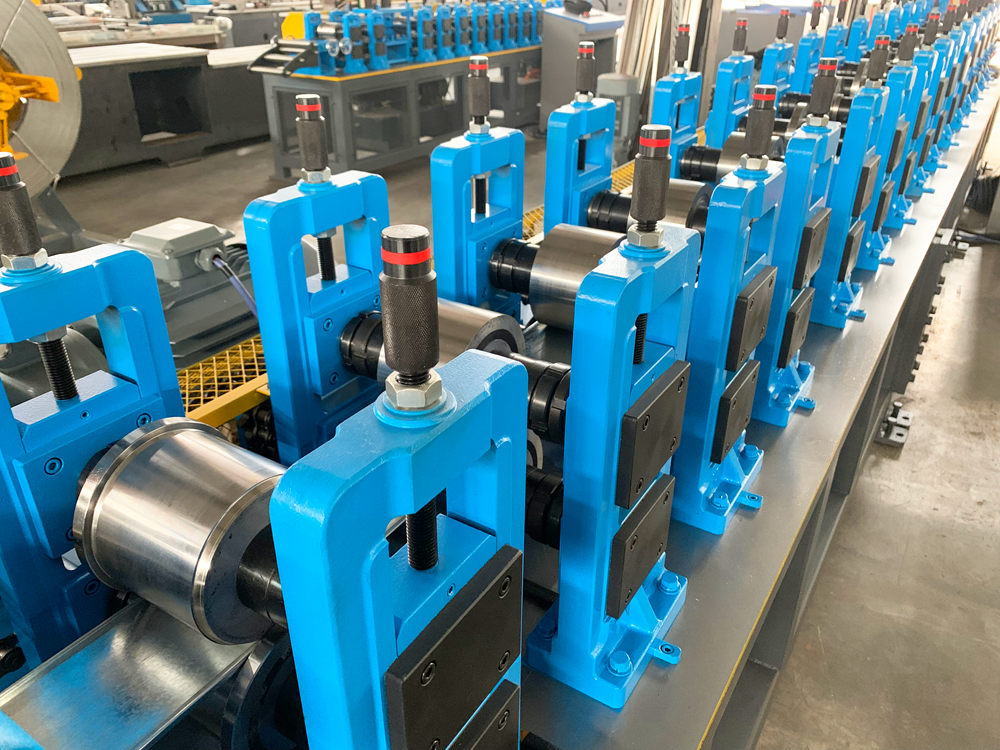

A stud and track frame forming machine operates by taking coil material—often galvanized steel—and processing it into precision-engineered studs and tracks. The process begins with feeding the coil into the machine, which then uses a series of rollers to shape the metal into the desired cross-section. This automatic process not only increases the speed of production but also significantly reduces material wastage, thus optimizing cost-efficiency. The machine cuts the formed sections to precise lengths, ready for immediate use in construction projects.

Experience with stud and track frame forming machines reveals their unmatched accuracy and speed. A well-calibrated machine ensures that all components produced are dimensionally consistent, reducing the risk of errors during onsite installation. This level of precision is crucial in constructing frames that must meet stringent engineering specifications and safety standards. Operators with extensive experience can attest to the reliability and performance that these machines bring to the table, often citing improved workflow and project turnaround times.

The expertise required to operate a stud and track frame forming machine is underscored by the need for skilled technicians who can manage the machine’s settings and troubleshoot potential issues. These professionals not only understand the mechanics of the machine but also have a keen understanding of the material properties they are working with. Their technical know-how ensures that the machine functions optimally and safely, providing peace of mind to project managers and builders alike.

stud and track frame forming machine

Authoritativeness in the realm of stud and track frame forming machines is evident in the rigorous standards and certifications these machines must meet. Leading manufacturers of these machines are often involved in the development of industry standards, contributing their insights to ensure that all equipment aligns with current safety and performance criteria. Clients often look for machines that are certified by recognized bodies, as this endorsement is an assurance of quality and dependability.

Trustworthiness is a core consideration in evaluating stud and track frame forming machines.

Construction companies rely on the guarantees of performance and durability that reputable manufacturers provide. Machines built with high-quality components and the latest technology are less likely to experience downtime, a critical factor in maintaining project timelines and budgets. Suppliers that offer comprehensive after-sales support and maintenance plans further enhance the trustworthiness of their products, ensuring that users have the assistance they need whenever issues arise.

The stud and track frame forming machine represents a leap forward in construction technology. As building design trends increasingly lean towards prefabrication and modular construction, these machines will continue to be at the forefront of innovation. They not only streamline the construction process but also contribute to more sustainable building practices by reducing waste and energy consumption.

In summary, the stud and track frame forming machine is indispensable in modern construction. Its role in producing high-quality building components quickly and efficiently cannot be understated. With experienced operators, expert design, authoritative certification, and trustworthy manufacturing, these machines exemplify the future of construction technology. As the industry evolves, keeping abreast of advancements in these machines will be essential for construction firms looking to maintain a competitive edge.