The Evolution and Impact of Stud and Track Frame Forming Machines

In the realm of modern construction and manufacturing, efficiency and precision are paramount. One of the pinnacle innovations catering to these demands is the stud and track frame forming machine. This sophisticated piece of equipment streamlines the production of metal framing components essential for wall construction, significantly enhancing productivity while maintaining high-quality standards.

Understanding Stud and Track Frame Forming Machines

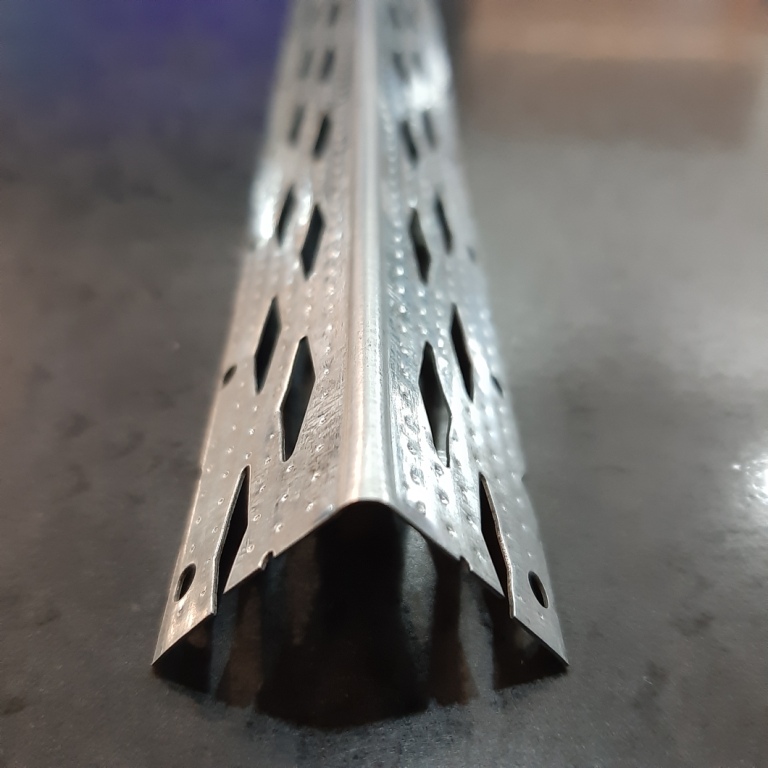

Stud and track frame forming machines are designed to produce the metal framing components used in constructing non-load-bearing walls, typically made from steel. The essential function of these machines is to create 'studs'—vertical members of the frame—and 'tracks'—horizontal components that guide and support the studs. Both elements are crucial for forming the structural framework for various building projects, including residential and commercial spaces.

The automation of this process not only allows for a consistent production quality but also reduces labor costs and manufacturing time. Advanced models utilize computer numerical control (CNC) technology, enabling precise cuts, holes, and bends as specified by digital designs. This increased accuracy minimizes material waste and supports the sustainability objectives of modern construction practices.

Key Features and Benefits

The modern stud and track frame forming machine comes equipped with a range of features that enhance its utility

1. High-Speed Production High-output machines can produce several feet of framing material in mere minutes. This rapid cycle time significantly accelerates the production process, allowing projects to meet tight deadlines.

2. Precision Engineering With CNC capabilities, these machines ensure that each piece is produced to exact specifications, reducing the need for excessive manual adjustments or corrections on-site. This precision translates to fewer construction errors and faster assembly.

3. Material Versatility These machines can often handle a variety of steel gauges and profiles, making them adaptable for different project requirements. This versatility is crucial as builders seek to optimize performance based on the unique demands of each construction project.

4. User-Friendly Interface Modern machines come with intuitive interfaces allowing operators to quickly set up and adjust parameters for different profiles and dimensions, reducing training time and improving operational efficiency.

5. Safety Features With built-in safety protocols and emergency shutdown capabilities, these machines are designed to protect operators while ensuring smooth production processes.

The Future of Construction

The advent of stud and track frame forming machines represents a significant leap forward in the construction industry. They facilitate faster project completion, enhance structural integrity, and contribute to cost savings that can be redirected towards other essential areas of building and design.

As the construction landscape evolves, the demand for energy-efficient and sustainable building practices is projected to increase. These machines can integrate with modern building methods such as prefabrication and modular construction, further revolutionizing how structures are erected. The ability to produce framing components in a controlled environment and transport them to the construction site for quick assembly aligns perfectly with the industry's shift towards efficiency and sustainability.

Conclusion

In conclusion, the stud and track frame forming machine is a crucial technological advancement in the construction industry. Its automation, precision, and efficiency not only optimize the production of essential building components but also support broader goals of sustainability and cost-effectiveness. As the industry continues to evolve, the role of these machines will undoubtedly grow, paving the way for innovative construction techniques and enhanced building practices worldwide. Embracing such technology is essential for stakeholders aiming to improve their competitive edge in an ever-demanding market.