The Evolution of Stud and Track Forming Machines

In the world of manufacturing and construction, efficiency, accuracy, and cost-effectiveness are paramount. Among the tools that enhance these factors, stud and track forming machines have emerged as invaluable assets. These machines are specially designed for the production of steel studs and tracks, which are essential components in the framing of modern buildings, particularly in the construction of interior walls and ceilings.

Understanding Stud and Track Forming Machines

Stud and track forming machines are intricate pieces of equipment that automate the process of creating metal studs and tracks from rolled steel. These machines operate by feeding raw steel coils into a specialized forming system that bends and cuts the metal into predefined shapes. The final products are lightweight, durable, and easily transported, making them a popular choice among contractors and builders.

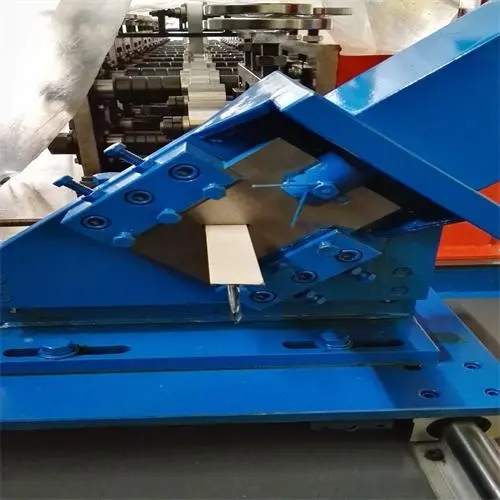

The fundamental design of these machines includes several critical components the uncoiler, forming stations, a punching unit, and a shear cutter. The uncoiler releases the steel coil, which is then fed through multiple forming stations where it is continuously bent to create the desired profile. The punching unit makes any necessary holes in the studs or tracks for electrical or plumbing installations. Finally, the shear cutter provides precise lengths, ensuring that the studs and tracks meet the specific requirements of the project.

Advancements in Technology

The technology surrounding stud and track forming machines has witnessed significant advancements over the years

. Modern machines are increasingly equipped with computer numerical control (CNC) systems that allow for greater precision and configurability. This innovation enables manufacturers to adjust the machine settings for different stud designs quickly, catering to diverse construction needs without requiring extensive downtime for recalibration.

Additionally, the integration of automation and robotics can be seen in newer models of forming machines. These machines can operate with minimal human intervention, reducing labor costs and increasing overall production efficiency. The use of sensors and real-time monitoring systems also enhances operational safety and quality control, ensuring that each product is manufactured to the highest standards.

Benefits to the Construction Industry

The benefits of utilizing stud and track forming machines in the construction industry are manifold. First and foremost, these machines significantly accelerate the production process. Traditional methods of stud and track creation involve manual labor and excessive time, which can lead to project delays. With a forming machine, thousands of studs and tracks can be produced in a single day, streamlining construction timelines.

Moreover, the consistency and precision achieved through automated processes are crucial. Errors in dimensions or quality can result in costly repairs and rework, compromising the integrity of the entire structure. By using stud and track forming machines, builders can ensure uniformity across all components, which directly translates to higher quality buildings.

Finally, the initial capital investment in a stud and track forming machine can lead to substantial long-term savings. While the upfront cost may seem daunting, the reduction in labor costs, the speed of production, and the decrease in material wastage make these machines a wise investment for construction firms looking to expand their operational capabilities.

Conclusion

In conclusion, stud and track forming machines play an essential role in the modern construction landscape. Their ability to produce high-quality, cost-effective framing components rapidly has transformed the building process, enabling faster project execution and enhanced structural reliability. As technology continues to evolve, these machines will likely become even more advanced, further solidifying their importance in the manufacturing and construction industries. For businesses aiming to stay competitive, investing in a stud and track forming machine is not just beneficial; it's imperative.