Stud and Track Forming Machine Revolutionizing Manufacturing Efficiency

In the rapidly evolving landscape of modern manufacturing, machinery plays a pivotal role in enhancing efficiency and precision. Among the significant advancements in manufacturing technology is the stud and track forming machine. This innovative equipment is designed to streamline the production of studs and tracks, which are essential components in various construction and industrial applications.

Understanding Stud and Track Forming Machines

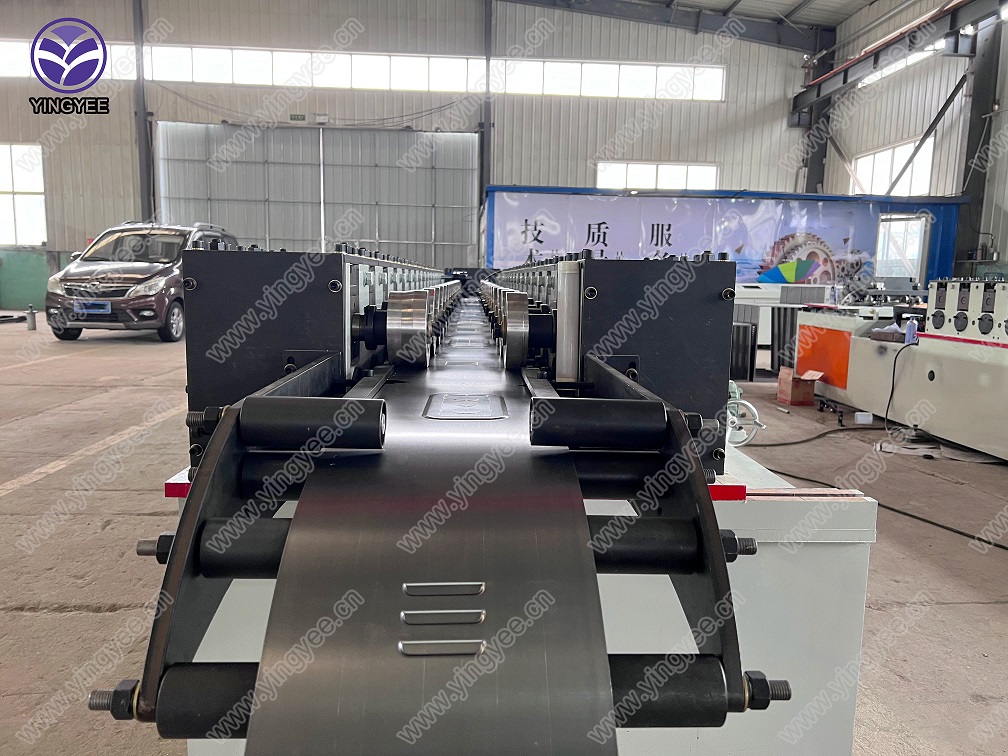

A stud and track forming machine is a specialized piece of equipment that creates metal studs and tracks used primarily in the construction of wall framing systems. These systems are crucial for supporting drywall and creating the internal structure of buildings. The machine operates on the principle of cold forming, which involves shaping metal sheets into desired profiles without the application of heat. This method not only enhances the strength of the material but also improves dimensional accuracy.

The forming process begins with a coil of steel, which is fed into the machine. The machine then uses a series of rollers to gradually shape the steel into the required stud or track profile. The versatility of these machines allows for the production of various sizes and configurations, making them invaluable to contractors and builders who need customized solutions.

Key Benefits of Stud and Track Forming Machines

1. Increased Efficiency One of the primary advantages of using a stud and track forming machine is the significant increase in production speed. Traditional methods, such as manual cutting and welding, are time-consuming and labor-intensive. In contrast, modern forming machines can produce large quantities of metal components in a fraction of the time, allowing businesses to meet demanding project deadlines.

2. High Precision and Consistency Consistency is crucial in construction, where even minor deviations can lead to structural issues. Stud and track forming machines deliver high precision in measurements, ensuring that each component meets strict tolerances. This uniformity reduces the likelihood of errors during installation, leading to overall enhanced quality in construction projects.

3. Cost-Effectiveness By automating the production process, businesses can significantly reduce labor costs associated with manual manufacturing. Additionally, the efficient use of raw materials minimizes waste, further contributing to cost savings. Companies can redirect these savings towards other critical areas of their operations, thereby enhancing overall profitability.

4. Design Flexibility Modern stud and track forming machines are equipped with advanced technology that allows for easy adaptation to different design specifications. This flexibility is crucial in the construction industry, where project requirements can frequently change. The ability to quickly switch between different profiles and dimensions enables manufacturers to serve a broader range of clients.

5. Improved Safety The automation provided by stud and track forming machines reduces the number of workers required on the factory floor, minimizing the risk of accidents associated with manual handling. Moreover, operators can control the machinery from a safe distance, further enhancing workplace safety.

Applications in the Construction Industry

Stud and track forming machines find diverse applications in the construction sector. They are primarily used in the production of

- Metal Studs These are essential for framing in commercial and residential buildings. Metal studs are known for their strength and resistance to warping compared to traditional wood studs.

- Tracks Tracks serve as the base support for metal studs, ensuring a robust framework for wall systems.

- Specialty Products Advanced machines can also create custom profiles for specific applications, catering to niche markets within the construction industry.

Conclusion

The stud and track forming machine represents a significant leap forward in manufacturing technology, particularly within the construction sector. Its ability to produce high-quality, precise components at an accelerated pace positions it as a crucial tool for builders and contractors seeking to enhance efficiency and reduce costs. As the demand for rapid and reliable construction solutions continues to grow, investing in advanced machinery like the stud and track forming machine will undoubtedly yield substantial benefits for manufacturers and stakeholders alike. As we look to the future, the importance of such innovative solutions will only increase, driving further advancements in manufacturing and construction practices.