The Evolution and Importance of Stud and Track Ceiling Forming Machines

In the realm of construction and interior design, ceiling systems play a crucial role in both aesthetics and functionality. Among the various methods used to create these ceilings, the stud and track system has gained significant popularity for its versatility and efficiency. The introduction of stud and track ceiling forming machines has revolutionized the construction industry by streamlining the process of creating these essential components.

Understanding Stud and Track Systems

The stud and track ceiling system consists of metal framework that supports ceiling panels or drywall. It is typically composed of horizontal tracks that are firmly attached to the walls and vertical studs that are placed within these tracks. This system provides a lightweight yet sturdy framework that can accommodate various ceiling designs, including acoustical treatments and recessed lighting.

One of the main advantages of using a stud and track system is its ability to create a smooth and even ceiling surface, which is crucial for both aesthetic appeal and functionality. Additionally, this system allows for considerable flexibility in design, enabling architects and contractors to experiment with different shapes and heights.

The Role of Stud and Track Ceiling Forming Machines

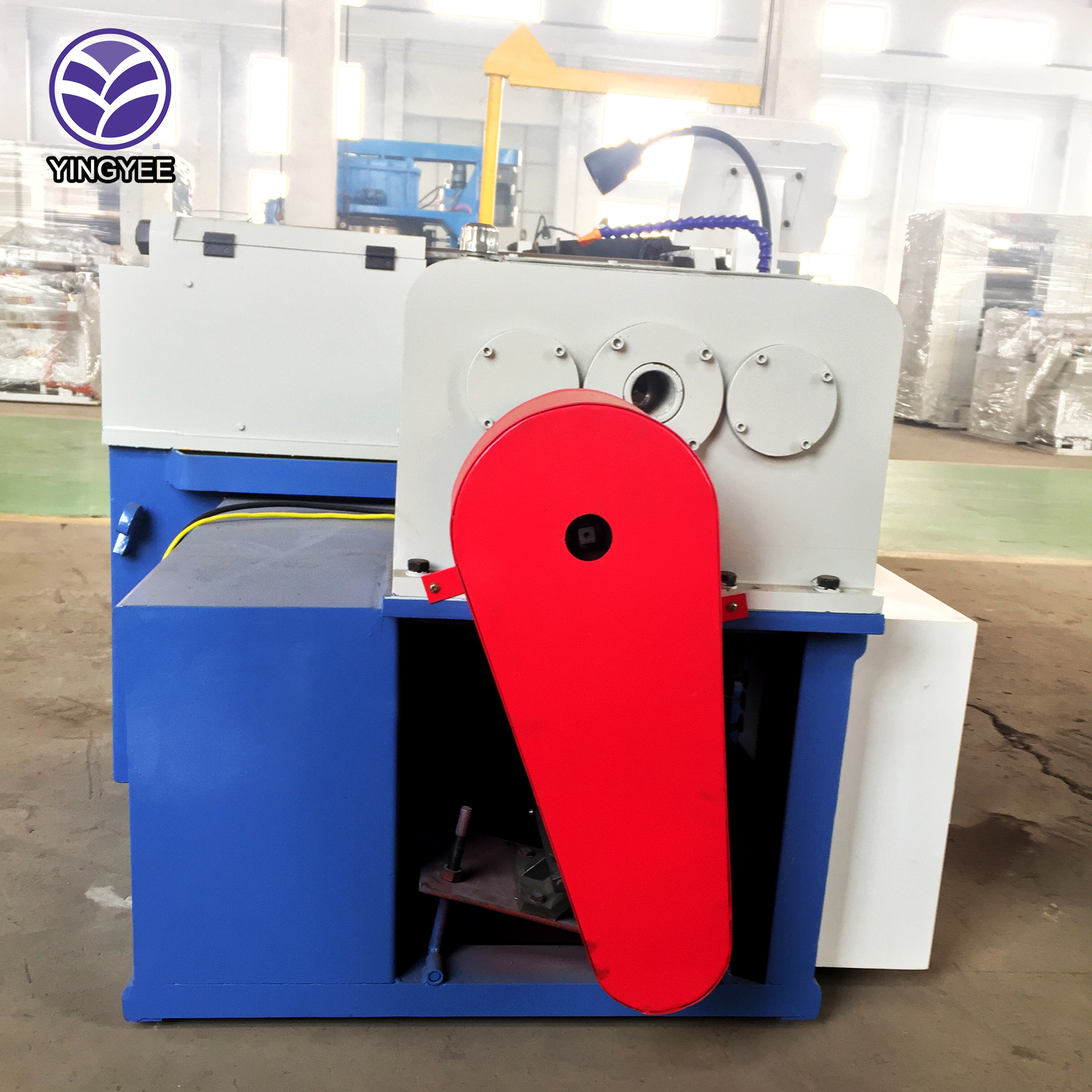

Stud and track ceiling forming machines are specialized tools designed to produce the metal components necessary for the installation of stud and track systems

. These machines automate the manufacturing process, significantly enhancing speed and precision. The use of such machines results in consistent quality, which is essential for meeting building codes and ensuring structural integrity.These machines can bend, cut, and assemble metal sheets into the required shapes for tracks and studs. Advanced models equipped with computer numerical control (CNC) technology allow for greater customization, enabling users to achieve specific dimensions and profiles based on project requirements. The automation of these processes not only saves time but also minimizes human error, which is a common issue in manual fabrication.

Benefits of Using Stud and Track Ceiling Forming Machines

1. Efficiency The automation provided by forming machines significantly reduces the time needed for production. This allows construction projects to progress more rapidly, minimizing delays and labor costs.

2. Precision With CNC technology, the machines produce factory-quality components that ensure uniformity in size and shape. This precision is critical in achieving a seamless installation of ceilings.

3. Cost-Effectiveness While the initial investment in forming machines may be substantial, the long-term savings in labor costs and material waste can be significant. Improved efficiency and accuracy lead to a better overall bottom line for contractors.

4. Customization Modern stud and track ceiling forming machines allow for intricate designs and specifications, offering greater flexibility to architects and builders. Whether it is for commercial spaces, residential homes, or unique architectural projects, these machines can cater to diverse needs.

5. Sustainability By optimizing material usage and decreasing waste, the operation of these machines contributes to more sustainable construction practices. Metal components are recyclable, further enhancing the ecological aspect of using stud and track systems.

The Future of Stud and Track Ceiling Forming Machines

As the construction industry continues to evolve, the technology behind stud and track ceiling forming machines is expected to advance significantly. Future trends may include the integration of artificial intelligence (AI) and machine learning for even more sophisticated customization and automation. Additionally, as sustainability becomes an increasingly important focus, machines that utilize eco-friendly materials and processes will likely gain traction.

In conclusion, stud and track ceiling forming machines represent a significant advancement in construction technology. They not only enhance efficiency and precision but also contribute to the overall quality and sustainability of building projects. As we look toward the future, embracing these innovations will be essential for contractors and architects aiming to create durable, attractive, and functional ceilings that meet the demands of modern spaces.