Understanding the Stud and Track Ceiling Forming Machine

In the realm of modern construction and drywall installation, efficiency and precision are paramount. One of the most innovative tools that has emerged to meet these demands is the stud and track ceiling forming machine. This versatile equipment revolutionizes the way suspended ceilings are constructed, ensuring not only speed but also the quality of the finished product.

What is a Stud and Track Ceiling Forming Machine?

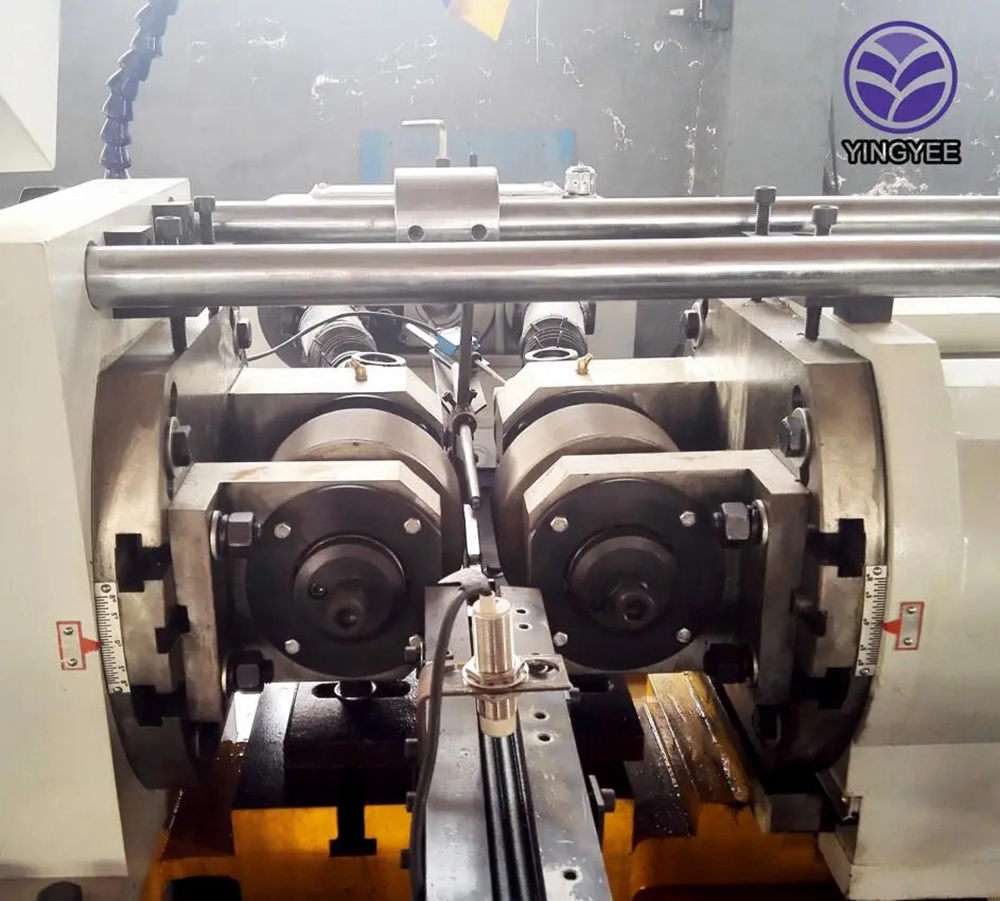

A stud and track ceiling forming machine is a specialized piece of machinery designed to fabricate metal tracks and studs used in ceiling construction. These components form the skeletal framework upon which drywall or other ceiling materials are attached. By automating the manufacturing process, this machine significantly reduces the time and labor involved in creating these structural elements.

Key Features and Benefits

1. Automated Production One of the primary advantages of using a stud and track ceiling forming machine is its ability to automate the production process. With programmable settings, operators can quickly switch between different sizes and specifications of studs and tracks, increasing versatility and reducing setup time.

2. Accuracy and Consistency Precision is crucial in construction to ensure that components fit correctly. These machines are designed to produce components with high accuracy, minimizing the risk of errors that can lead to costly rework. The consistency in output helps maintain the structural integrity of the ceiling systems.

3. Material Efficiency By optimizing the cutting and forming processes, a stud and track ceiling forming machine can minimize waste. This not only reduces costs but also contributes to more sustainable construction practices. More efficient use of raw materials leads to less environmental impact.

4. Higher Output Compared to manual fabrication methods, automated machines can produce significantly higher volumes of components in a fraction of the time. This increased productivity allows construction projects to stay on schedule, meeting tight deadlines without compromising quality.

5. User-Friendly Operation Modern machines often come equipped with intuitive control panels and user interfaces, making them easier to operate even for those who may not have extensive technical training. This accessibility can lead to a smoother adoption of the technology on job sites.

Applications in Construction

The stud and track ceiling forming machine is widely used in both commercial and residential construction projects. It is particularly beneficial in large-scale developments where speed and precise measurements are essential. From office buildings to retail spaces, the ability to quickly deliver high-quality framing components has made this machine a staple in the contractor’s toolkit.

Additionally, interior renovations and remodeling projects also benefit from this technology. As spaces are reconfigured and ceilings are redesigned, the ability to produce custom-sized studs and tracks on-site can significantly enhance the speed of the renovation process.

Future Trends

Looking ahead, the stud and track ceiling forming machine is likely to evolve along with advancements in technology. Innovations such as artificial intelligence and machine learning may lead to smarter machines capable of adapting to various design specifications in real-time. Additionally, integration with Building Information Modeling (BIM) systems can streamline workflows further, allowing for even greater precision and efficiency in construction.

Conclusion

The stud and track ceiling forming machine represents a significant advancement in construction technology. By automating the production of essential components for ceiling systems, it offers numerous benefits including enhanced productivity, reduced waste, and improved accuracy. As the construction industry continues to embrace innovation, this machine will undoubtedly play a crucial role in shaping the future of building design and construction practices. Investing in such technology not only facilitates quicker project completions but also helps sustain quality standards in an ever-demanding environment.