Stud and Track Forming Machine Revolutionizing Construction and Manufacturing

In the ever-evolving landscape of construction and manufacturing, efficiency and precision are paramount. One technological advancement that has significantly contributed to these sectors is the stud and track forming machine. This specialized equipment is designed to streamline the production of metal frames, particularly for commercial and residential buildings, thereby enhancing productivity and reducing labor costs.

At its core, a stud and track forming machine is engineered to produce C-shaped and U-shaped steel studs and tracks, which are essential components in drywall systems. The machine utilizes high-quality steel coils, feeding them through a series of rollers that sequentially bend and shape the metal into the required profile. This innovative process ensures consistent quality and dimensional accuracy, which are critical for structural integrity.

One of the main advantages of using a stud and track forming machine is its ability to automate the manufacturing process. By reducing the need for manual labor, it minimizes human error while increasing output. Operators can set specific parameters on the machine for different profiles, allowing for quick changes between production runs. This versatility is particularly beneficial for contractors who require various sizes and shapes for different projects, as it allows for rapid adaptation to client needs without compromising on quality.

Moreover, the stud and track forming machine contributes to sustainability efforts within the construction industry. The use of steel, a recyclable material, helps reduce waste and promotes a more environmentally friendly approach to building. Additionally, the machine's efficiency means less energy consumption compared to traditional framing methods, further supporting eco-friendly practices.

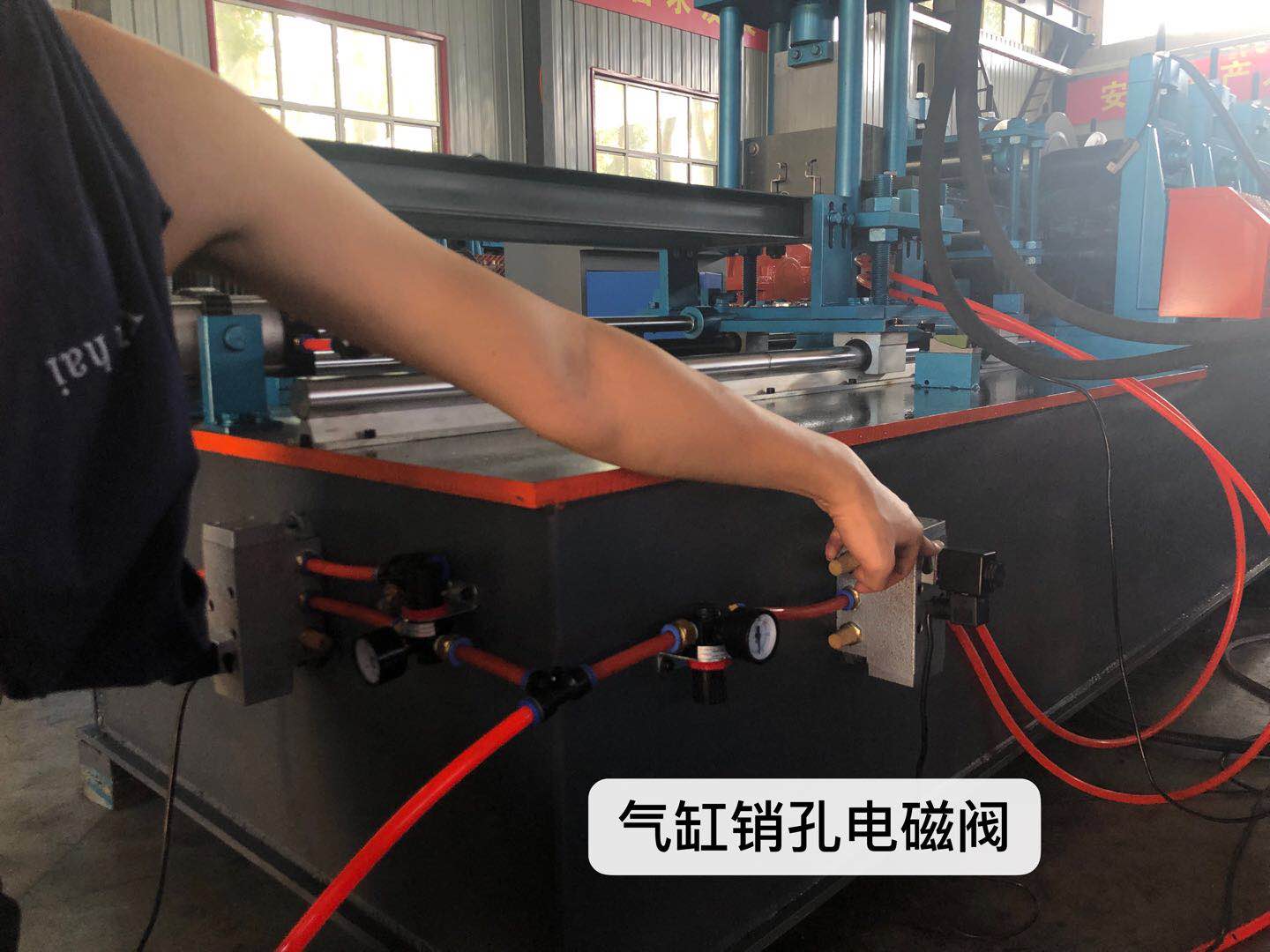

Maintenance and operational ease are also noteworthy features of these machines. With user-friendly interfaces and advanced monitoring systems, operators can quickly identify issues and perform routine maintenance, ensuring minimal downtime. This reliability is crucial in fast-paced construction environments where delays can result in significant financial losses.

Furthermore, the evolution of stud and track forming machines has seen the integration of advanced technologies like computer numerical control (CNC) and automated cutting systems. These innovations enable even greater precision and customization, as machines can be programmed for complex designs, enhancing their adaptability to various architectural styles.

In conclusion, the stud and track forming machine stands as a testament to the advancements in construction technology. Its efficiency, versatility, and sustainability make it an invaluable asset for modern manufacturing and construction projects. As the industry continues to embrace automation and innovation, these machines will play a crucial role in shaping the future of building practices, leading to faster, more reliable, and environmentally friendly construction processes. The potential for growth and adaptation in this field is vast, marking an exciting era for construction professionals and stakeholders alike.