The significance of strut channel roll forming emerges as a game-changer in the industrial landscape, especially for those seeking unparalleled precision and efficiency. This technology represents a leap forward in how metal channels are manufactured, offering businesses a competitive edge through innovation and advanced engineering.

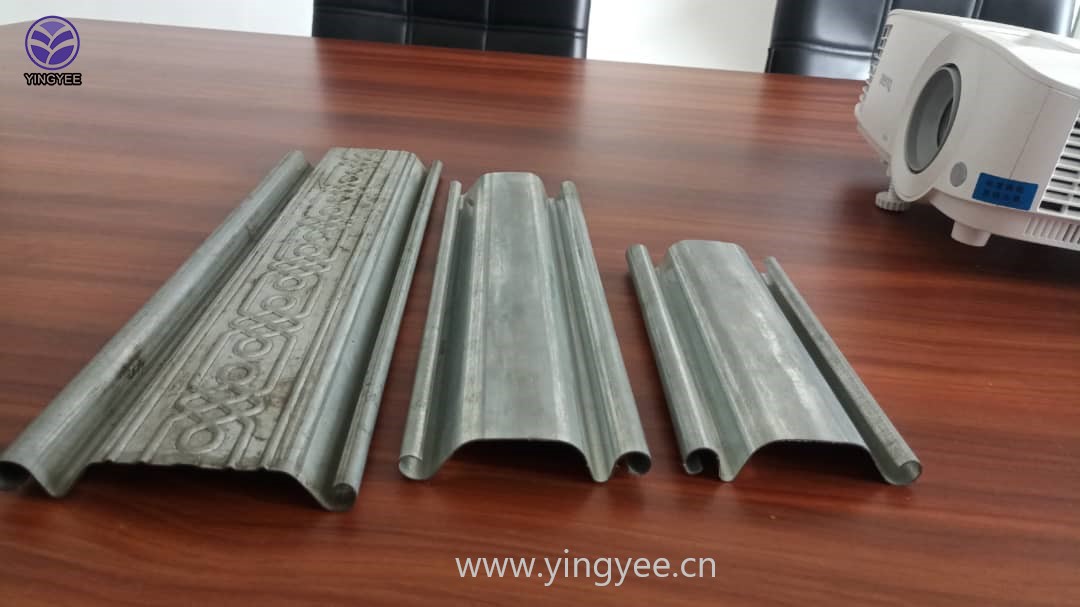

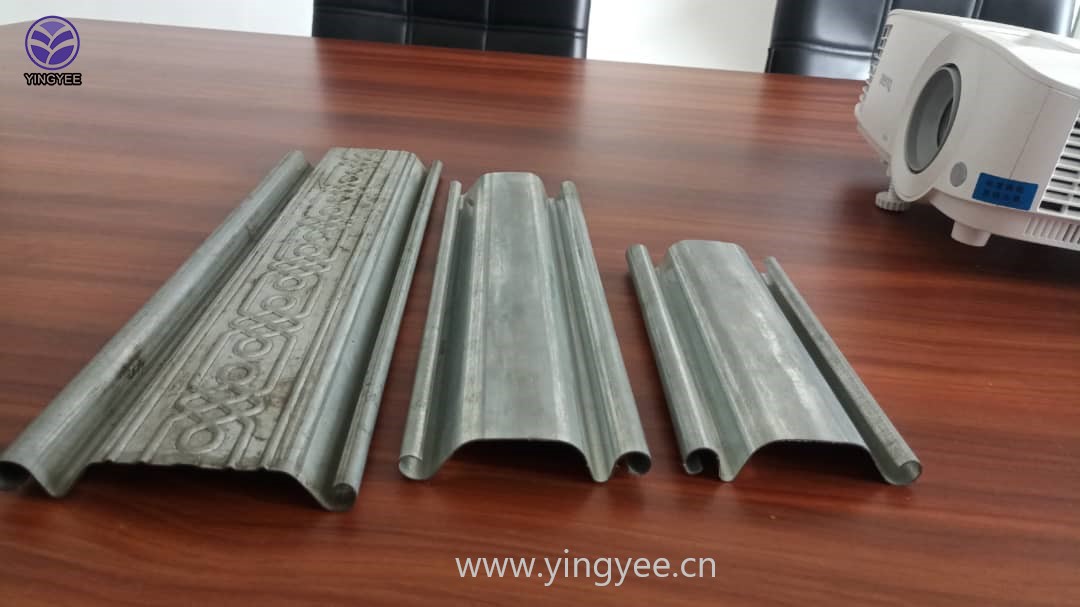

Strut channels, primarily made from materials like steel or aluminum, are integral to countless applications ranging from construction to electrical support systems. The roll forming process transforms flat metal sheets into structured channels, utilizing a series of precisely calibrated rollers. This method not only enhances the material’s structural integrity but also ensures consistent quality across largescale production.

From an engineering perspective, roll forming offers distinct advantages over conventional manufacturing techniques. It provides superior strength-to-weight ratios, making the strut channels ideal for structural applications that demand durability without excessive weight. This precision is achieved through expert calibration of tooling equipment, which is a testament to the process's expertise and meticulous engineering.

Moreover,

roll forming is lauded for its efficiency. Unlike traditional stamping or bending methods, it minimizes waste and accelerates production speed. A continuous process allows for longer lengths of strut channels to be produced with minimal interruptions, thus reducing downtime and lowering production costs. This efficiency translates to competitiveness in pricing, benefitting both manufacturers and their customers by offering high-quality products at more affordable rates.

The authoritativeness of strut channel roll forming is underscored by the technology’s adaptability. Customization is at the forefront, with advanced software and machinery allowing for the adjustment of dimensions and profiles to meet specific project requirements. This flexibility is invaluable in industries where bespoke solutions are requisite for success.

strut channel roll forming

Beyond customization, the trustworthiness of the roll forming process is evident in its widespread adoption by leading manufacturers. Companies choose roll forming for its proven track record in delivering precise and reliable components that meet rigorous industry standards. This adherence to quality is crucial, particularly in sectors where safety and performance cannot be compromised.

Furthermore, real-world applications illustrate the transformative impact of strut channel roll forming. In the renewable energy sector, for instance, these channels are essential for mounting solar panels. Their strength and adaptability ensure panels are securely positioned, even in challenging environments. This reliability bolsters confidence among engineers and end-users alike, who seek sustainable and long-lasting solutions.

Finally, sustainability is another aspect where roll forming technology shines. The process inherently conserves material, reducing surplus and encouraging eco-friendly production practices. As industries increasingly prioritize sustainability, the eco-conscious nature of roll forming becomes a compelling reason for its adoption.

In summary, the strut channel roll forming process stands out for its sophisticated combination of experience, expertise, authoritativeness, and trustworthiness. By delivering high-quality, customizable, and efficient metal channels, it supports various industries in achieving their performance and sustainability goals.