Understanding Strut Channel Roll Forming A Comprehensive Overview

Strut channel roll forming is a specialized manufacturing process used to create metal channels that offer structural support in various construction and industrial applications. This method allows manufacturers to produce high-quality, cost-effective strut channels that are essential for assembly and mounting purposes in buildings, machinery, and numerous fixtures.

What is Strut Channel?

Strut channels, commonly known as strut, are metal framing systems that provide versatile and robust support structures. Made primarily from steel, aluminum, or other alloys, these channels are characterized by their U-shaped profile with pre-punched holes along their length. This design facilitates the attachment of various components, making strut channels an ideal choice for mounting electrical conduits, pipe systems, and HVAC equipment.

The Roll Forming Process

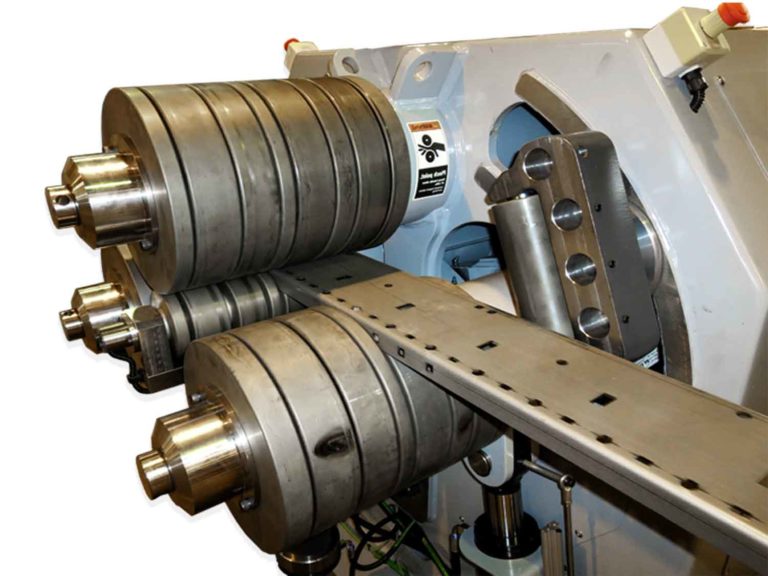

Roll forming is a continuous bending operation in which a long strip of metal is progressively shaped through a series of rollers. This method allows for the creation of complex profiles without the need for extensive cutting or machining, making it highly efficient. The roll forming process consists of the following steps

1. Material Preparation Sheets or coils of metal are prepared for processing. The choice of material and thickness is crucial, as it directly impacts the strength and durability of the final product.

2. Feeding The prepared metal is fed into the roll forming machine, which consists of multiple sets of rollers. Each set of rollers is designed to progressively shape the metal strip into the desired profile.

3. Shaping As the metal passes through the rollers, it is gradually bent into the specified strut channel shape. This step requires precise alignment and control to ensure uniformity in the finished product.

4. Cutting Once the desired length is achieved, the continuous strip is cut to size. This can be done using shearing tools or laser cutting, depending on the required precision.

5. Finishing After forming and cutting, the channels may undergo additional finishing processes such as surface treatment, coating, or galvanization to enhance corrosion resistance.

Advantages of Strut Channel Roll Forming

1. Precision and Consistency Roll forming is known for its ability to produce uniform profiles with tight tolerances. This precision ensures components fit together seamlessly during assembly.

2. Efficiency The continuous nature of roll forming allows for high production speeds, making it a cost-effective solution for large-scale manufacturing.

3. Material Optimization Minimal waste is generated during the roll forming process as the metal strip is utilized efficiently. Any scrap metal can often be recycled, reducing overall material costs.

4. Customization Roll forming allows for a wide range of custom profiles. Manufacturers can design channels to meet specific load requirements or accommodate unique installation conditions.

5. Reduced Labor Costs Automation in the roll forming process minimizes the need for manual labor, thus lowering production costs and increasing safety in the workplace.

Applications of Strut Channels

Strut channels find extensive use across various industries. In construction, they are commonly employed in electrical and plumbing installations, where they support conduit and piping systems. The automotive industry utilizes strut channels for assembling various components, and manufacturing plants often use them for creating frames to support equipment. Additionally, in HVAC systems, strut channels provide necessary reinforcement for ductwork, ensuring stability and durability.

Conclusion

Strut channel roll forming is a highly effective manufacturing process that plays a critical role in producing essential structural components used throughout multiple industries. Combining efficiency, precision, and versatility, this process not only meets the demands of modern construction and manufacturing but also supports innovations in design and engineering. As industries continue to evolve, the importance of reliable, high-quality strut channels will undoubtedly remain a cornerstone of structural integrity and functionality. By understanding the advantages and applications of strut channel roll forming, businesses can better appreciate the value it brings to their operations and the broader marketplace.