The Importance of Structural Roof Deck Cold Bending Machines in Modern Construction

In the rapidly evolving world of construction, the demand for efficiency, durability, and precision has led to the development of specialized machinery that can cater to these needs. One such innovation is the structural roof deck cold bending machine. This device plays a crucial role in the fabrication of roof decks, a component essential for ensuring the structural integrity and longevity of buildings. In this article, we will explore the functionality, benefits, and applications of cold bending machines, shedding light on their significance in the construction industry.

Understanding Cold Bending

Cold bending, as a process, involves the deformation of metal without the application of heat. This technique is particularly beneficial for materials such as steel, which can be manipulated to various shapes while retaining its structural properties. The cold bending process is favored in structural applications as it allows for the creation of complex profiles that are both lightweight and strong.

Features of Structural Roof Deck Cold Bending Machines

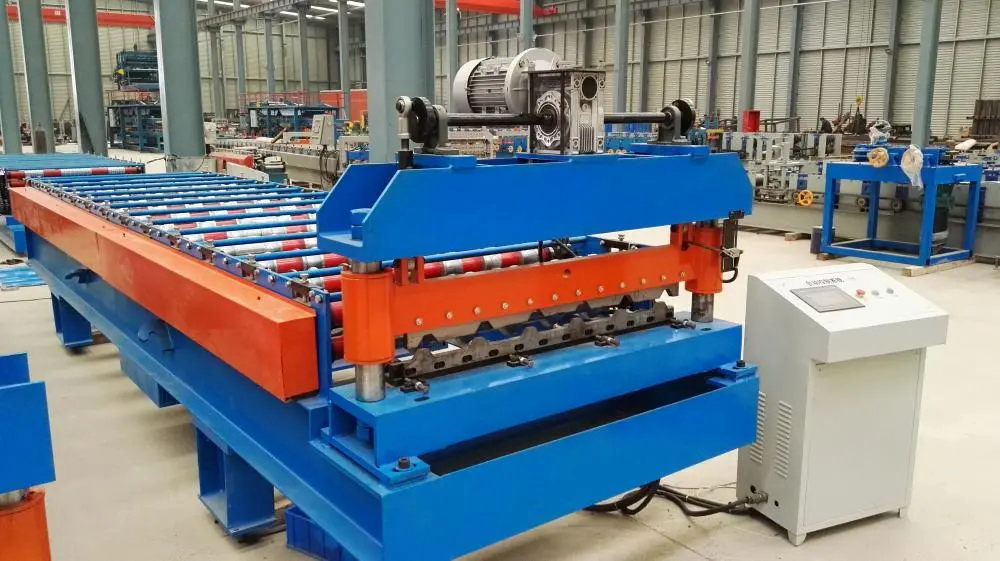

Structural roof deck cold bending machines are specifically designed to shape metal sheets into roof deck profiles. These machines typically feature an array of rollers and guides that facilitate precise bending. The primary features include

1. Adjustable Rollers These machines allow for the adjustment of roller positions to accommodate different material thicknesses and bending angles. This versatility is necessary for adapting to various project requirements.

2. High Production Speed Cold bending machines are capable of high-speed operation, significantly reducing the time required to produce roof deck components. This efficiency is essential in meeting tight construction deadlines.

3. Automated Controls Many modern machines incorporate advanced automation technologies, enabling operators to input specifications easily and achieve consistent results with minimal manual intervention.

4. Durability and Reliability Built from robust materials, these machines are designed to withstand the rigors of daily use in a manufacturing environment, ensuring long-term reliability and minimal downtime.

Advantages of Using Cold Bending Machines

Employing structural roof deck cold bending machines yields numerous advantages for construction professionals

1. Cost-Effectiveness By streamlining the production process, these machines reduce labor costs and minimize material wastage, leading to overall savings on construction projects.

2. Enhanced Structural Integrity The precision with which these machines produce roof deck profiles translates to better fitting components, ultimately contributing to the structural integrity of the building.

3. Flexibility and Customization Cold bending machines can produce a variety of shapes and sizes, allowing for customized solutions that cater to specific architectural designs or engineering requirements.

4. Improved Safety With reduced manual handling of materials and automated processes, the risk of workplace accidents decreases. Operators can perform tasks with enhanced safety and comfort.

Applications in Construction

Cold bending machines are widely used in various construction applications, particularly in commercial buildings, warehouses, and industrial facilities. Some specific uses include

- Metal Roof Decks These machines can create the desired profiles for metal roof decks, which serve as a support system for roofing materials. The high strength-to-weight ratio of cold-bent steel makes it ideal for this application.

- Floor Decking Cold bending machines also produce floor decking components, contributing to the floor structures of multi-story buildings.

- Bracing Systems In addition to roofs and floors, these machines can create components used in bracing systems, enhancing the overall stability and safety of structures.

Conclusion

The structural roof deck cold bending machine represents a significant advancement in construction technology, providing an efficient and effective means of producing essential building components. As the construction industry continues to embrace innovative solutions to improve productivity and quality, cold bending machines will undoubtedly play a vital role in shaping the future of building design and fabrication. Investing in modern machinery not only enhances operational capabilities but also ensures that construction professionals can meet the ever-evolving demands of the industry. In a field where safety, efficiency, and precision are paramount, the cold bending machine stands out as an invaluable asset.