Strong Structure Furring Channel Making Machine Enhancing Efficiency in Construction

In the ever-evolving construction industry, efficiency and precision have become paramount to meeting the demands of modern architecture. One of the innovations that have significantly impacted the field is the Furring Channel Making Machine. This advanced equipment plays a crucial role in the production of furring channels, which are integral in the installation of drywall and other facade elements. This article delves into the importance of strong structure furring channel making machines and how they benefit the construction sector.

Understanding Furring Channels

Furring channels are horizontal members made of galvanized steel or other durable materials. They are used as a support framework for attaching drywall or plasterboard to walls and ceilings. By creating a level surface, furring channels help in achieving a smooth finish for interior surfaces. The strength and quality of these channels are crucial, as they must support heavy materials while ensuring stability and alignment in the construction process.

The Role of Furring Channel Making Machines

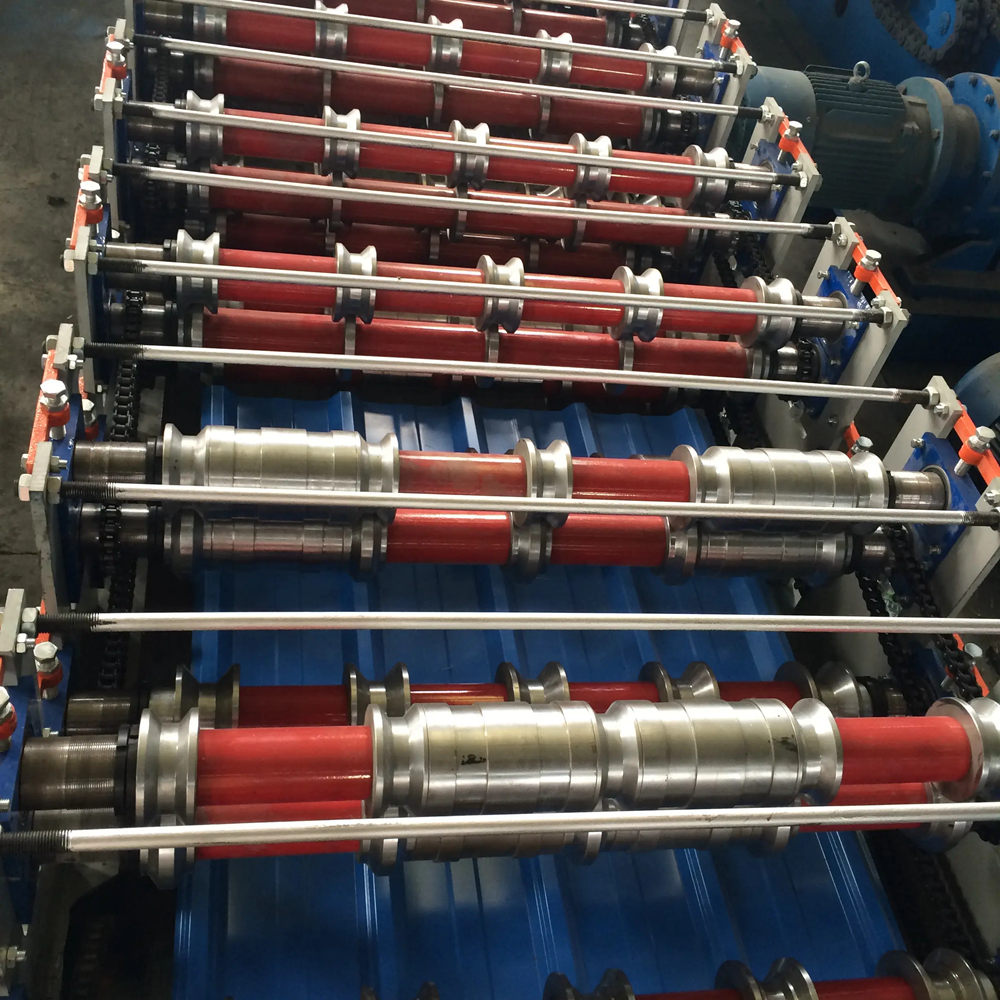

Furring channel making machines are specialized equipment designed for the high-speed production of these essential building components. They streamline the manufacturing process by enabling the rapid and precise fabrication of furring channels in various sizes and specifications. The machines utilize advanced technology to cut, bend, and shape metal strips into the desired channel profiles, ensuring uniformity and high quality in each product.

Key Features and Benefits

1. Efficiency and Speed One of the most significant advantages of using a furring channel making machine is the increase in production efficiency. These machines can produce furring channels much faster than manual methods, allowing manufacturers to meet high demand with minimal lead time.

2. Precision Engineering With automated processes, furring channel machines reduce human error, ensuring that each channel is manufactured to exact specifications. This precision is vital in construction, where even minor discrepancies can lead to significant problems during installation.

3. Cost-Effectiveness By automating the production process, companies can lower their labor costs and maximize output. This efficiency translates to cost savings, making it more economical for businesses to produce high-quality furring channels.

4. Versatility Modern furring channel making machines are designed to handle a variety of profiles and materials. This versatility allows manufacturers to cater to different construction needs, producing channels that comply with various building codes and standards.

5. Durable Construction Strong structure furring channels, produced using advanced machinery, can effectively withstand environmental stresses and load requirements. The enhanced strength of these channels contributes to the overall integrity of buildings, ensuring safety and longevity.

Technological Advancements

Recent advancements in technology have further refined the capabilities of furring channel making machines. Features such as computer numerical control (CNC) allow for greater customization and the ability to program complex designs with ease. These machines can be integrated with production management systems, enabling real-time monitoring and optimization of the manufacturing process.

Moreover, innovations in material science have led to the development of stronger, lightweight metals, which can be processed by these machines. This progress not only enhances the functionality of the furring channels but also contributes to sustainable construction practices by reducing material waste.

Conclusion

The strong structure furring channel making machine represents a pivotal development in the construction industry. By enhancing the production of furring channels, these machines increase efficiency, precision, and cost-effectiveness, ultimately leading to better-quality construction outcomes. As the demand for innovative and durable building solutions continues to grow, the role of such advanced machinery will only become more critical. For contractors and builders looking to improve their processes and ensure reliable installations, investing in a furring channel making machine is a strategic move towards achieving long-term success in a competitive market.