In the ever-evolving landscape of manufacturing, the stretch bending forming machine emerges as a pivotal innovation, offering precision and efficiency in shaping complex metal components. This specialized equipment is indispensable in industries like automotive, aerospace, and construction, where the demand for high-quality, contoured metal parts is ever-increasing.

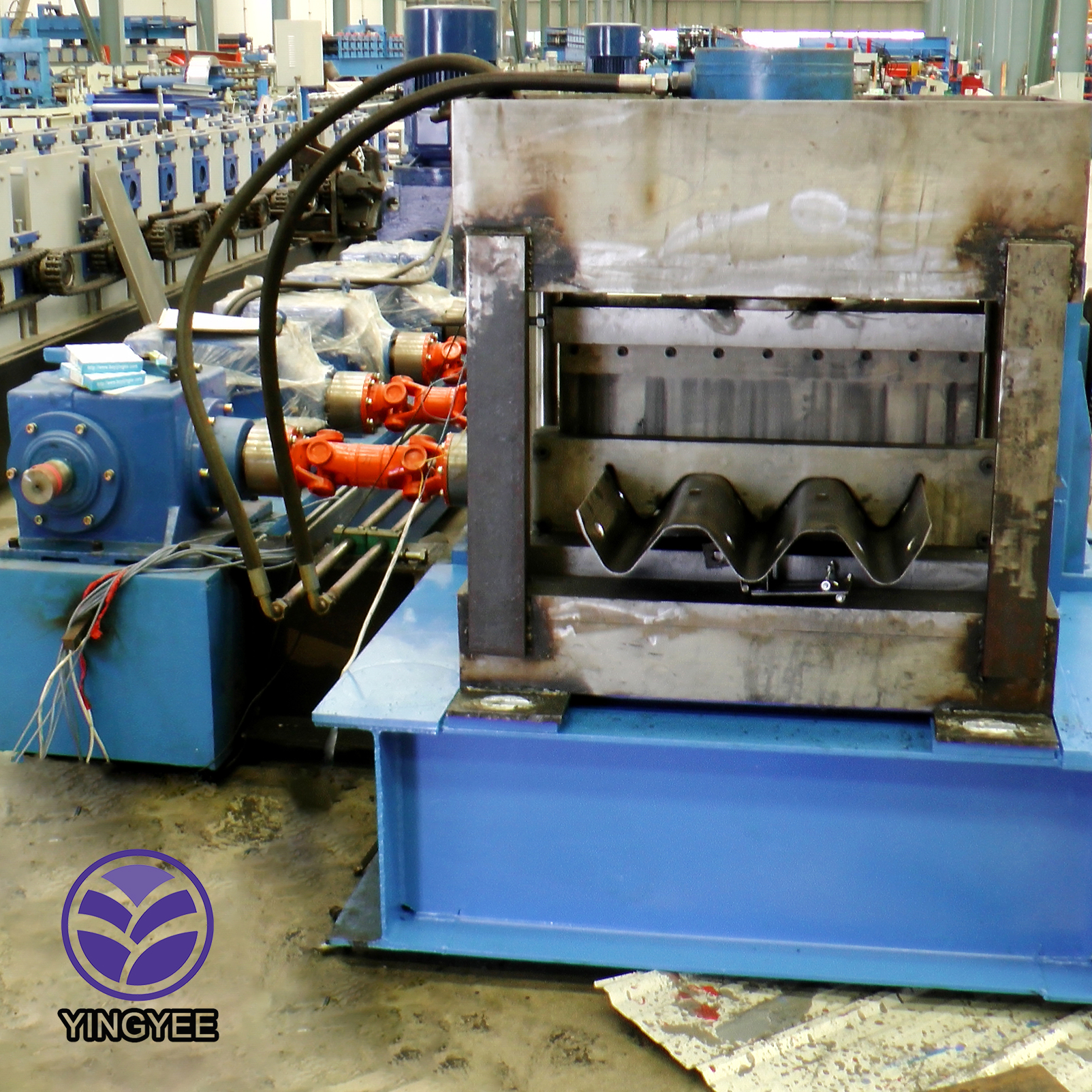

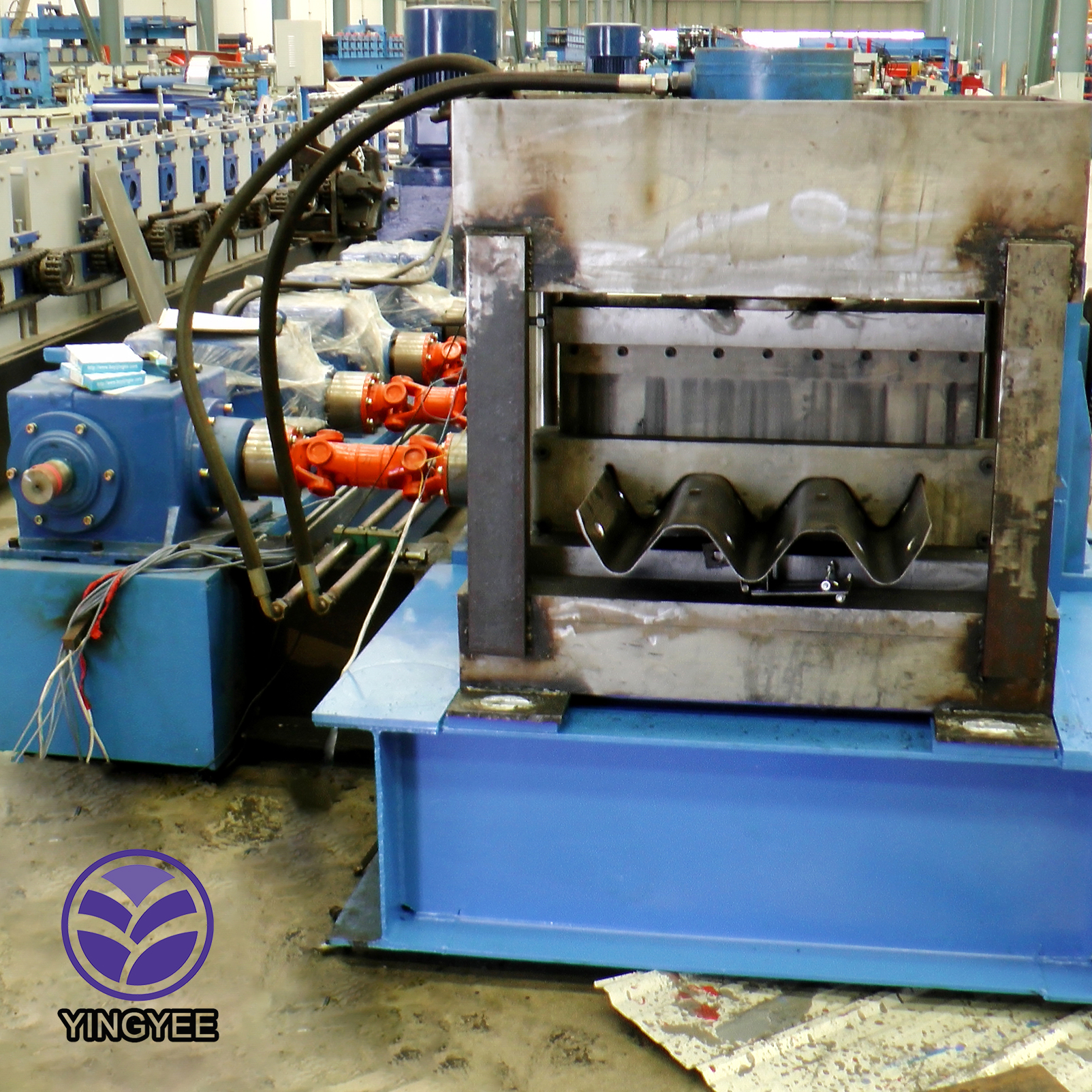

Granted a front-row seat to the realms of engineering marvels, the stretch bending forming machine exemplifies the synergy of state-of-the-art technology and material science. At its core, this machine is designed to bend and form metal profiles into predetermined shapes with minimal deformation or structural compromise, a crucial requirement in critical applications.

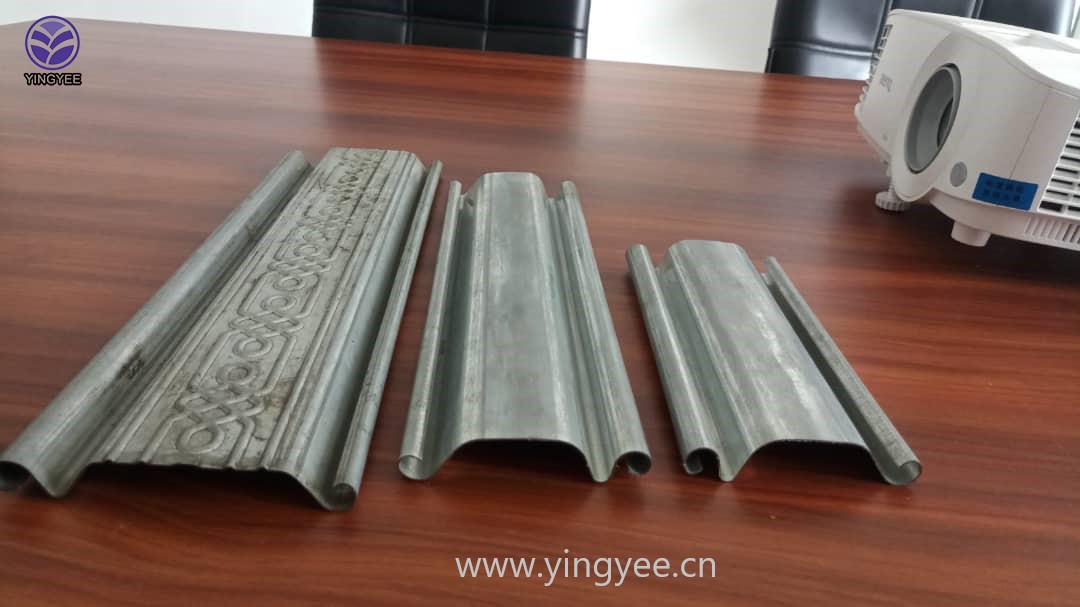

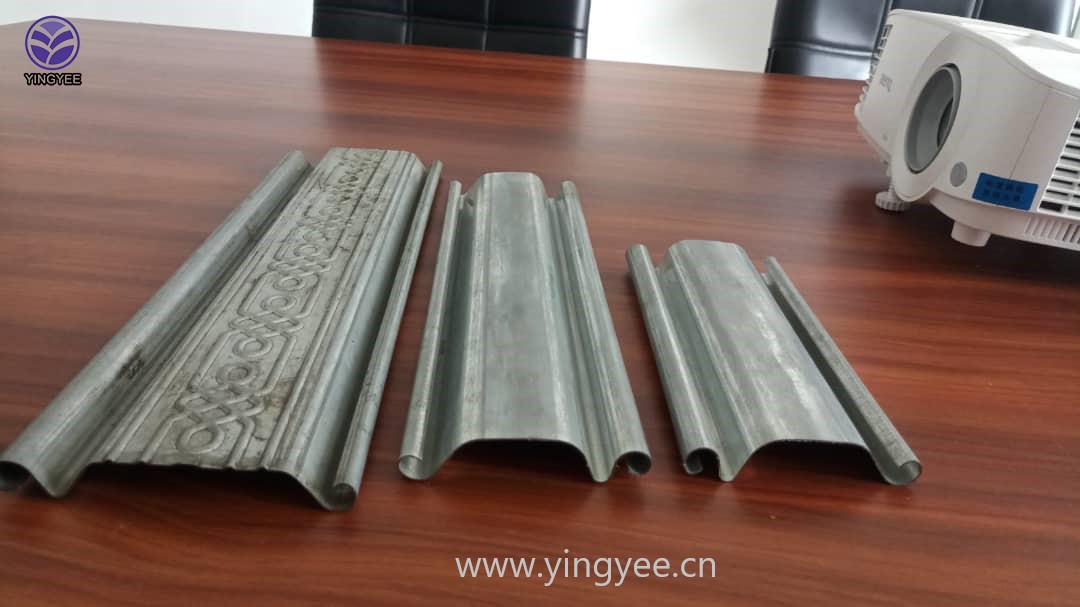

Imagine crafting the sleek curves of an aircraft fuselage or the seamless edges of automotive body panels. Such precision would be elusive without the stretch bending process—a marvel in the ability to exert even force distribution across the metal surface. The inherent flexibility in its application makes it suitable for a range of materials, from aluminum and steel to more exotic alloys, addressing diverse industrial needs.

Expertise in the operation of stretch bending forming machines is not merely about understanding the mechanical nuances of the equipment; it encompasses an in-depth grasp of the materials being used and the intended applications of the formed components. An adept operator combines technical acumen with an artist’s eye, ensuring each component retains not only its structural integrity but also the specified aesthetic characteristics.

One of the standout features of OEM (Original Equipment Manufacturer) stretch bending forming machines is the customization they offer. Tailoring this equipment to meet specific manufacturing parameters allows companies to optimize production lines, enhancing productivity and reducing waste. This is where the expertise of OEMs becomes a cornerstone offering bespoke solutions that align with intricate project specifications, ensuring companies stay competitive in a global marketplace.

stretch bending forming machine oem

The authoritativeness of a stretch bending forming machine OEM is often measured by the breadth of their industry experience and the extent of their technological advancements. Trusted OEMs not only supply machinery but also provide comprehensive support services, from the installation and initial training to ongoing maintenance and optimization. This relationship ensures that clients can achieve maximum operational efficiency, with minimal downtime—an essential factor in today's fast-paced manufacturing environment.

Delving deeper into the trustworthiness of these OEMs, their commitment to innovation, quality standards, and customer satisfaction plays a pivotal role. By investing in cutting-edge research and adhering to stringent quality controls, reputable OEMs safeguard their client’s investments, guaranteeing machinery longevity and consistent performance under demanding conditions.

Moreover, a trusted OEM will have a transparent operational ethos, offering clients visibility into their manufacturing processes, raw material sourcing, and after-sales service policies. This transparency builds trust, fostering long-term partnerships that benefit both the provider and the client through shared success stories and technological advancements.

From an SEO perspective, capturing the essence of a stretch bending forming machine’s role in modern industry involves a strategic balance of experiential narratives and technical prowess. Crafting compelling content that weaves testimonials, case studies, and expert insights ensures visibility and engagement, catering not only to search engine algorithms but to the discerning reader seeking authoritative information.

In conclusion, the stretch bending forming machine stands as a testament to industrial ingenuity, seamlessly blending experience, expertise, authoritativeness, and trustworthiness. Whether for an engineer designing the next generation of electric vehicles or an architect envisioning groundbreaking skyscrapers, this machinery offers the precision and reliability needed to transform visionary ideas into tangible realities. As industries continue to evolve, the stretch bending forming machine remains an invaluable asset, driving efficiency and innovation across the manufacturing spectrum.