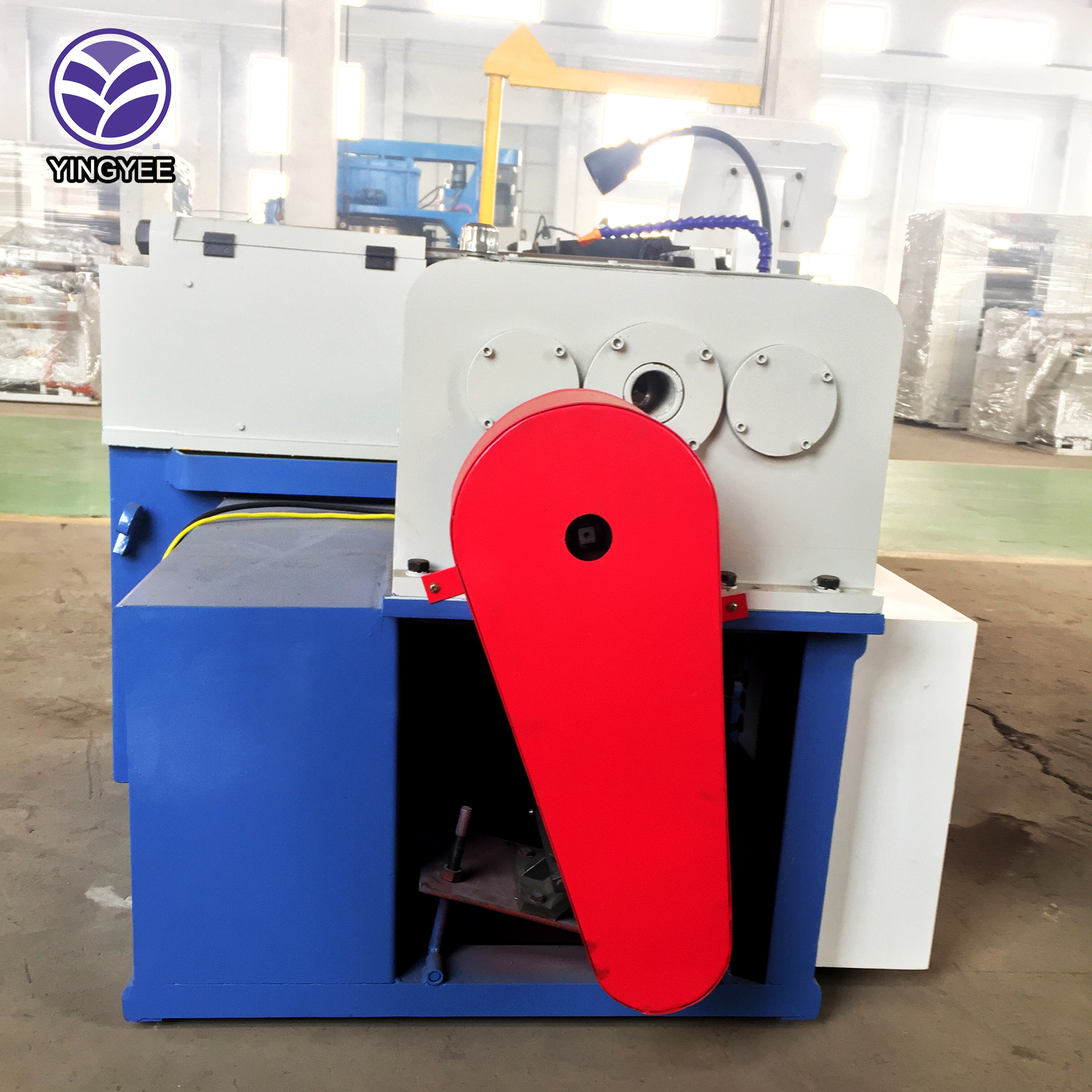

Understanding Stretch Bending Forming Machines An Overview of OEM Solutions

Stretch bending forming machines have become indispensable tools in various manufacturing processes, particularly in the fabrication of metal parts. These machines are designed to perform stretch bending operations, which involve selectively deforming materials to achieve desired shapes and configurations. As Original Equipment Manufacturers (OEMs) develop tailored solutions to meet industry-specific needs, understanding the functionality and benefits of stretch bending forming machines is crucial for manufacturers seeking efficiency and precision.

The Basics of Stretch Bending

Stretch bending is a metal forming process that combines tensile and bending forces to shape a material. Unlike traditional bending methods, where material is merely pushed or pulled to achieve a form, stretch bending ensures that the material is elongated as it is bent. This technique is particularly useful for producing components with complex geometries and tight radii that would be difficult to accomplish with standard bending methods.

The stretch bending process begins with the material, usually in sheet or profile form, being clamped at both ends. While one end remains stationary, hydraulic or mechanical force is applied to the other end, creating tension. This tension, combined with bending, allows for a more controlled and accurate deformation, minimizing the risk of wrinkling or cracking.

Key Features of Stretch Bending Forming Machines

1. Precision Control Modern stretch bending machines are equipped with advanced control systems that allow operators to program specific bending angles, lengths, and tension levels. This precision not only enhances the quality of the output but also provides flexibility in the production of different parts without the need for extensive tool changes.

2. Versatility Stretch bending forming machines are capable of working with various materials, including metals and certain composites. This versatility enables manufacturers to use the same machine for different projects, saving time and resources.

3. Efficiency Automation plays a significant role in the efficiency of these machines. Automated feeding systems and robotic loaders can significantly reduce manual labor, speed up production cycles, and increase overall output.

4. Durability OEM stretch bending machines are built to withstand the rigors of industrial use. High-quality materials and superior engineering ensure longevity and reliability, which are critical in production settings where downtime can be costly.

5. Customization OEMs often offer customized solutions that cater to the specific needs of a manufacturer. This can involve adjustments in machine size, additional features for processing specific materials, or modifications to accommodate unique production workflows.

Applications of Stretch Bending Forming Machines

Stretch bending forming machines are utilized across various industries, including automotive, aerospace, construction, and furniture manufacturing. In the automotive sector, for instance, these machines are used to fabricate components such as structural beams and chassis parts, which require both strength and precision. In aerospace, stretch bending is crucial for the production of fuselage frames and wing structures, where weight reduction and structural integrity are paramount.

Moreover, in the construction industry, stretch bending machines are used to create architectural elements and structural components, allowing for innovative designs that integrate strength and aesthetic appeal. The furniture industry also benefits, producing elegantly curved furniture pieces that combine form and function.

The Future of Stretch Bending Technology

As technology continues to evolve, the future of stretch bending forming machines looks promising. The incorporation of Industry 4.0 principles—such as real-time data monitoring, predictive maintenance, and smart automation—will further enhance the capabilities and efficiency of these machines. Additionally, the ongoing exploration of new materials and forming techniques may lead to even more advanced stretch bending applications.

Conclusion

Stretch bending forming machines represent a critical technological advancement in the realm of metal forming processes. Their ability to provide precise, efficient, and versatile solutions makes them an essential asset for manufacturers across various industries. As OEMs continue to innovate and refine their offerings, the potential for stretch bending technology to meet the evolving demands of production will only grow, paving the way for more sophisticated and efficient manufacturing practices in the future. For businesses looking to optimize their production capabilities, investing in a stretch bending forming machine can yield significant returns in terms of quality, efficiency, and versatility.