The Importance of Straightening Machines in Modern Manufacturing

In the ever-evolving landscape of manufacturing and industrial production, precision and efficiency are paramount. As industries strive to enhance quality and reduce production times, specialized equipment has become indispensable. Among these tools, straightening machines emerge as a critical component, particularly in the processing of metal and other materials. This article explores the significance of straightening machines, their types, applications, and technological advancements shaping their future.

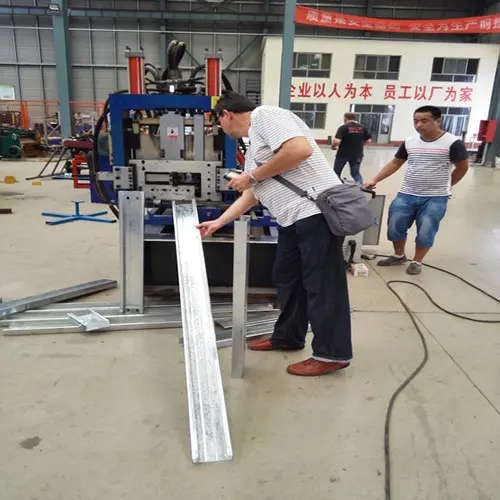

Straightening machines are designed to correct the shape and alignment of metal components. These machines are crucial in various industries, including automotive, aerospace, construction, and electronics. They serve to eliminate any warping or deformation that may occur during manufacturing or handling processes. The business of metalworking relies heavily on the integrity and accuracy of metal parts, making straightening machines essential for ensuring that components meet stringent specifications.

There are several types of straightening machines available, each tailored to specific materials and applications. The most common types include roll straighteners, press straighteners, and stretch straighteners. Roll straighteners involve a series of rollers that progressively apply pressure to the material, gradually aligning it to the desired specifications. This method is particularly effective for long materials such as bars and tubes. Press straighteners utilize hydraulic presses to exert significant force on deformed parts, making them suitable for thick and robust materials. Stretch straighteners, on the other hand, work by applying a tensile force to the material, making them ideal for thin sheets and delicate components.

The applications of straightening machines are diverse and far-reaching. In the automotive industry, for instance, manufacturers rely on straightening machines to ensure that chassis components, axles, and frames are perfectly aligned, contributing to vehicle safety and performance. In aerospace, precision is critical; straightened parts contribute to the structural integrity of aircraft, where even the slightest deviation can lead to catastrophic failures. Furthermore, in construction, straightened steel beams and reinforcements are essential for the stability and durability of buildings and infrastructure.

Technological advancements have significantly influenced the design and functionality of straightening machines. Automation and computerization have led to enhanced precision and efficiency. Modern straightening machines are often equipped with sensors and software that monitor the shape of components in real time, allowing for immediate adjustments to be made during the straightening process. This not only improves the accuracy of the straightened products but also minimizes waste and rework, ultimately leading to cost savings for manufacturers.

Moreover, advancements in materials and engineering practices have allowed for the creation of more robust and efficient straightening machines. Manufacturers are increasingly turning to lightweight materials and innovative designs that increase the machine's capacity and speed, enabling them to handle a wider range of materials and thicknesses.

Sustainability is another critical factor influencing the development of straightening machines. As industries aim to reduce their environmental footprint, manufacturers are exploring energy-efficient designs and eco-friendly materials. Straightening processes that consume less energy and produce minimal waste are gaining traction, aligning with the global move towards sustainable manufacturing practices.

In conclusion, straightening machines play a vital role in ensuring the quality and precision of metal components across various industries. With advancements in technology and a growing emphasis on sustainability, these machines are poised to become even more efficient and pivotal in modern manufacturing. As industries continue to evolve, the importance of straightening machines will undoubtedly remain at the forefront, driving improvements in product quality and operational efficiency.