The Evolution and Importance of Storage Rack Shelf Frame Roll Forming Machines

In the quest for efficient storage solutions, the design and construction of storage rack shelf frame systems have become crucial in various sectors, including warehousing, retail, and manufacturing. One of the key technologies that has enabled the effective production of these systems is the roll forming machine, specifically designed for creating storage rack shelf frames.

Understanding Roll Forming Technology

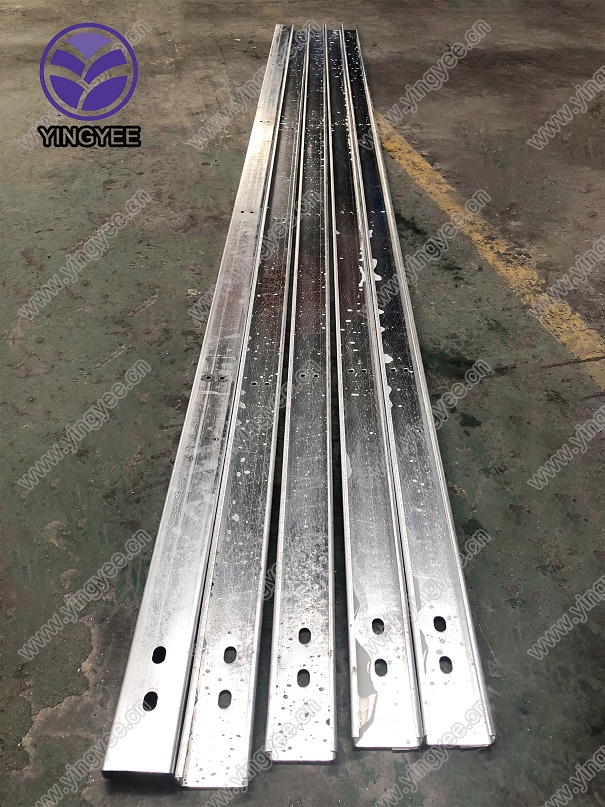

Roll forming is a continuous bending operation in which a long strip of metal is gradually shaped into a desired profile by passing it through a series of rollers. This method is particularly advantageous for producing uniform and precise components, making it ideal for the high-demand manufacturing of storage rack shelves. Storage rack shelf frame roll forming machines are engineered to produce components that are not only structurally sound but also optimized for strength and weight.

Features of Storage Rack Shelf Frame Roll Forming Machines

Modern roll forming machines are equipped with several features that enhance their productivity and versatility. Typically, these machines allow for

1. Customizable Designs Manufacturers can modify roll forming dies to produce various shelf frame designs. This flexibility enables the production of different rack structures to meet specific market needs.

2. High Production Speeds Roll forming machines are renowned for their high throughput, allowing manufacturers to produce large quantities of frames quickly, thus meeting increasing market demands.

3. Material Efficiency Roll forming processes minimize material waste as they utilize long strips of metal, ensuring that every inch of material is used effectively. This efficiency reduces production costs and environmental impact.

4. Durability and Strength The continuous bending process enhances the strength of the metal, making the resulting storage racks capable of holding substantial weight, crucial for warehouses that store heavy items.

Applications of Storage Rack Shelf Frames

The application of roll formed shelf frames spans numerous industries. In warehouses, adjustable shelving systems aid in maximizing space utilization and improving organizational efficiency. In retail, storage racks created with these machines are vital for displaying products attractively while ensuring they are easily accessible to customers. The manufacturing sector relies on these robust storage solutions for organizing raw materials and finished goods, promoting an efficient workflow.

The Future of Roll Forming Machines

With the advancement of technology, the future of storage rack shelf frame roll forming machines looks promising. Innovations such as automated processing, smart manufacturing, and AI-driven quality control systems are on the rise. These technologies will increase production efficiency, enhance safety measures, and further reduce material waste. Furthermore, the integration of sustainable practices in manufacturing processes is becoming a standard, shaping the future of production in various industries.

Conclusion

In conclusion, the role of storage rack shelf frame roll forming machines is paramount in the modern manufacturing landscape. Their ability to produce strong, durable, and customizable storage solutions positions them as essential tools for meeting the demands of various industries. As technology continues to evolve, these machines will likely become even more efficient, offering manufacturers enhanced capabilities to succeed in an increasingly competitive market. The importance of having reliable and innovative storage solutions cannot be overstated, and roll forming machines are at the forefront of this revolution. Through continued investment in technology and sustainability, the future of storage rack systems looks bright and resilient.