Understanding the Storage Rack Forming Machine An Essential Tool for Modern Warehousing

In today's fast-paced industrial environment, the efficient management of storage space is critical for operational success. Storage racks play a pivotal role in organizing inventory and maximizing available space. To achieve high levels of efficiency and durability in storage solutions, businesses are increasingly turning to specialized machinery, such as the storage rack forming machine. This advanced equipment is designed to produce high-quality storage racks that meet the varying demands of modern warehousing and logistics.

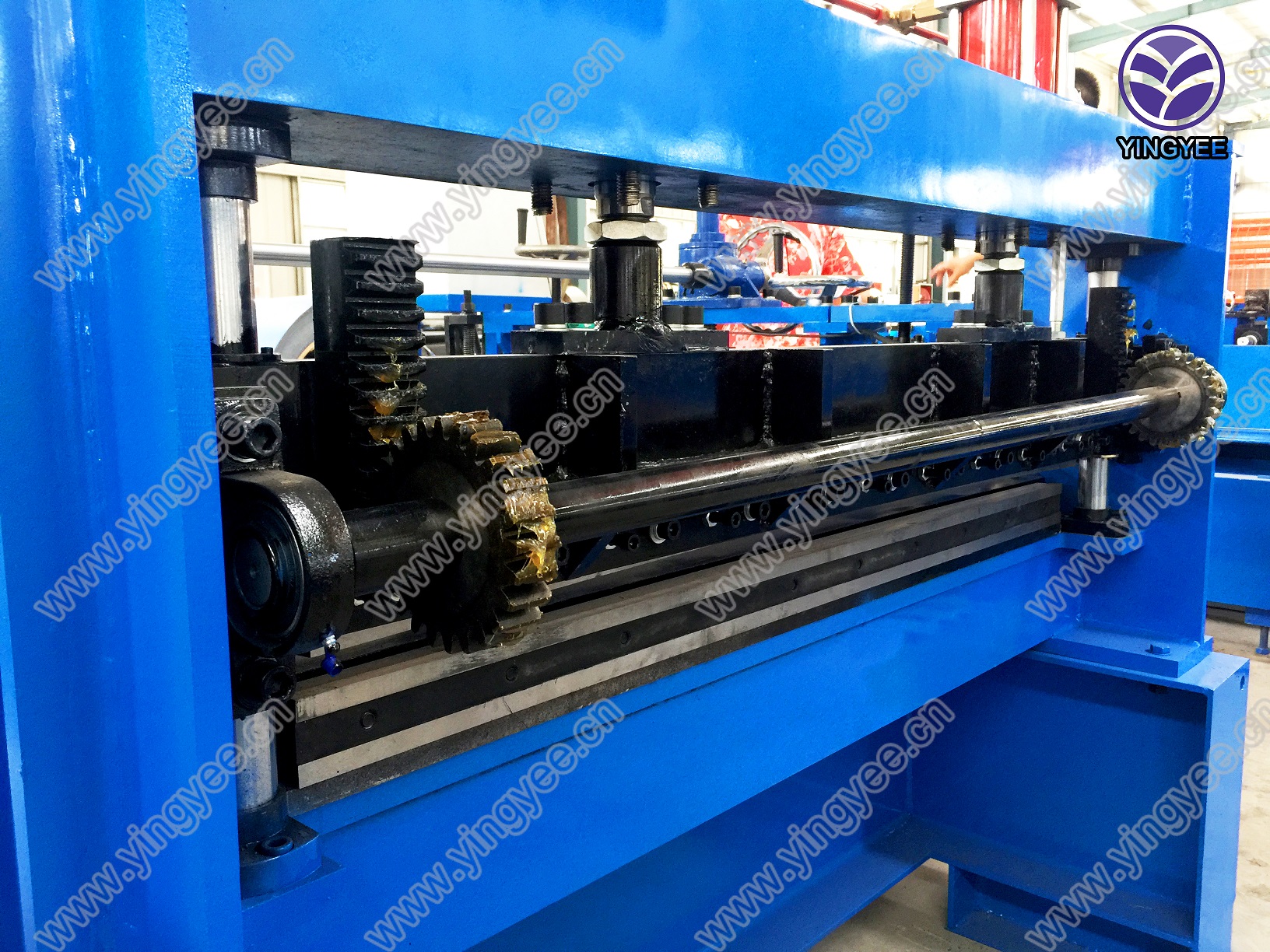

A storage rack forming machine operates by utilizing a series of processes that shape and assemble metal components into robust rack systems. Typically, this machine employs a roll forming technique, where flat steel coils are fed into the machine and progressively transformed into shaped sections. This process allows for the continuous production of storage rack components, such as beams, uprights, and braces, ensuring uniformity and precision in every piece.

One of the primary advantages of using a storage rack forming machine is the significant boost in production efficiency. Traditional methods of manufacturing storage racks, which often involve manual labor and separate machining processes, can be time-consuming and prone to errors. In contrast, a forming machine automates these tasks, reducing labor costs and speeding up the manufacturing cycle. This automation not only translates to lower production costs but also enables businesses to respond swiftly to changing market demands.

In addition to efficiency, storage rack forming machines also enhance product quality. The precision of the roll forming operation ensures that all components are made to exact specifications, resulting in strong and reliable storage racks. This is crucial for businesses that require heavy-duty racking solutions to support substantial loads. The uniformity in the manufacturing process also facilitates easy assembly and installation, thereby reducing downtime during warehouse setup.

Another key feature of modern storage rack forming machines is their adaptability. These machines can be configured to produce various styles and sizes of storage racks, which is particularly beneficial for companies with diverse warehousing needs. Whether a business requires classic pallet racking systems, mobile shelving units, or custom-designed fixtures, a storage rack forming machine can be adjusted accordingly, making it a versatile solution for any storage requirement.

Moreover, the evolving landscape of e-commerce and supply chain practices has increased the demand for dynamic storage solutions. As warehouses need to accommodate more products and changing inventory levels, the flexibility offered by storage rack forming machines becomes even more crucial. Companies can easily revise their storage rack designs without extensive retooling or reconfiguration, allowing for a more agile response to market trends.

Finally, the environmental impact of manufacturing processes cannot be overlooked. Many modern storage rack forming machines are designed to minimize waste production by optimizing material usage. Innovations in technology mean that metal scraps and offcuts can be recycled, contributing to a more sustainable production cycle. This aspect appeals to companies striving for greener operations and improved corporate responsibility.

In conclusion, the storage rack forming machine is an invaluable asset in the industrial sector. Its ability to enhance efficiency, ensure product quality, provide adaptability, and promote sustainability makes it an essential tool for businesses aiming to optimize their storage solutions. As industries continue to evolve, investing in such machinery will undoubtedly lead to a more organized and productive future for warehousing and logistics.