Storage Rack and Beam Roll Forming Machine A Revolution in Warehouse Solutions

In today’s fast-paced industrial environment, efficiency and space optimization are paramount for businesses looking to thrive. One of the most effective solutions for maximizing storage capabilities is the use of storage racks. The underlying technology that enables these racks to be produced at scale is the roll forming machine, specifically designed for the manufacturing of storage racks and beams. This article delves into the mechanics and advantages of the storage rack and beam roll forming machine, illuminating its critical role in modern warehousing.

Understanding Storage Racks

Storage racks are essential fixtures in warehouses and distribution centers, significantly enhancing the organization and accessibility of inventory. They come in various designs, including selective racks, drive-in racks, and pallet flow racks, each catering to specific storage needs. The design and manufacturing of these racks demand precision and strength, which is where roll forming technology steps in.

What is a Roll Forming Machine?

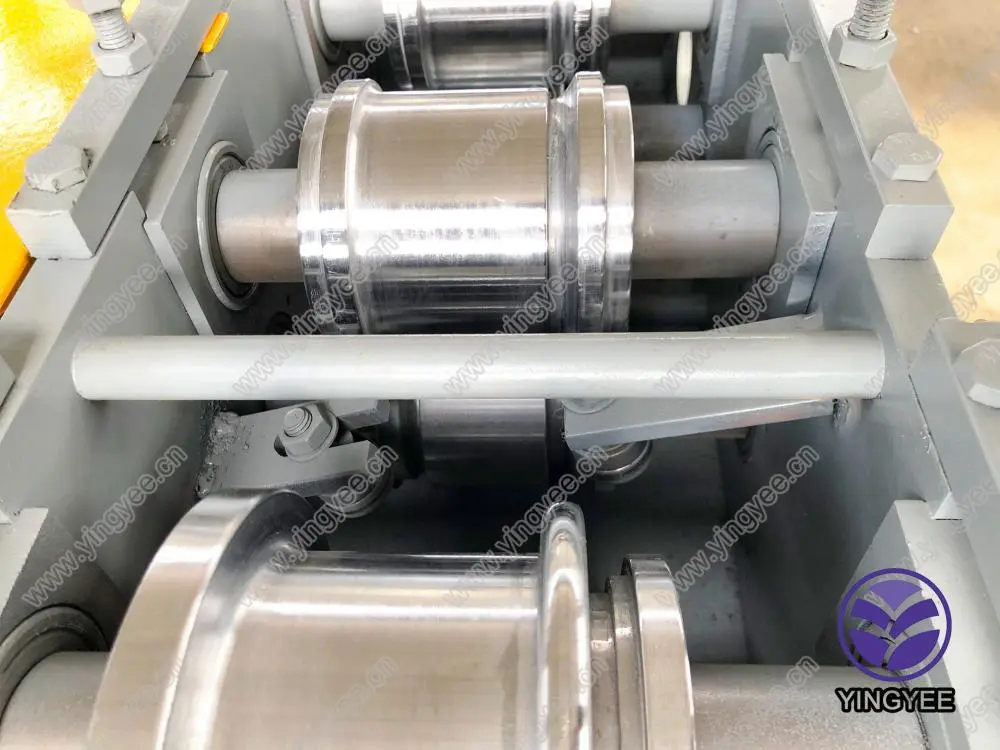

A roll forming machine is a specialized piece of equipment used to convert flat metal sheets into shaped profiles through a continuous bending operation. As the sheet metal passes through a series of rollers, it undergoes sequential bending and shaping to achieve the desired cross-sectional configuration. In the context of storage racks, roll forming machines are crucial for producing the vertical sides (uprights) and horizontal beams that provide structural integrity and load-bearing capacity.

The Process of Roll Forming for Storage Racks

The roll forming process begins with the selection of the appropriate metal, often cold-rolled steel or galvanized steel, for its strength and durability. The sheet metal is then fed into the roll forming machine, where it is guided through a series of forming stations. Each station is designed to shape the metal incrementally, ensuring consistent dimensions and surface quality.

One of the key advantages of roll forming is its efficiency. It allows for the production of long lengths of material with minimal waste, making it a cost-effective option for manufacturers. Furthermore, the continuous nature of the process means that high volumes of storage rack components can be produced rapidly, aligning with the ever-increasing demand for storage solutions in various industries.

Advantages of Using Roll Forming Machines for Storage Racks

1. Customizability Roll forming machines can be easily adjusted to produce different profiles and sizing, allowing manufacturers to cater to specific client requirements. This flexibility is a significant advantage in a market where customization is often necessary.

2. High Strength and Durability The continuous nature of the roll forming process improves the structural integrity of the products. Storage racks made from rolled steel exhibit excellent strength-to-weight ratios, making them capable of supporting heavy loads without compromising safety.

3. Cost-Effectiveness The efficiency of the roll forming process results in lower production costs. Fewer material scraps and faster production times lead to savings that can be passed on to the customer, making roll-formed storage racks a competitive option in the market.

4. Enhanced Quality Control Automated roll forming machines often come equipped with advanced monitoring and control systems, ensuring that each component is manufactured to stringent quality standards. This minimizes defects and enhances the overall reliability of the storage systems.

5. Reduced Lead Times With the capability for rapid production runs, companies can significantly reduce lead times for their storage systems. This is especially important in fast-paced industries where space optimization and inventory management are critical for maintaining competitive advantage.

Conclusion

The storage rack and beam roll forming machine represents a significant advancement in warehouse technology, providing solutions that cater to the growing demands of industry. By improving efficiency, offering customization options, and ensuring high-quality products, this technology is instrumental in helping businesses optimize their operations. As industries continue to evolve and expand, the importance of reliable and effective storage solutions will only increase, making roll forming machines a vital piece of the logistics and warehousing puzzle. Embracing this technology will empower companies to meet their storage needs while maximizing productivity and safety.