Understanding Storage Rack and Beam Roll Forming Machines

In the realm of modern manufacturing, efficiency and precision are paramount. One technological advancement that has significantly contributed to these goals is the introduction of storage rack and beam roll forming machines. These machines are integral in producing one of the core structures used in warehouses and logistics—storage racks. This article will delve into the functionality, advantages, and significance of these machines in industrial applications.

What is a Roll Forming Machine?

A roll forming machine is a type of industrial equipment that shapes metal sheets into desired profiles through a continuous bending process. The metal sheets pass through a series of rollers that gradually form them into specific shapes and dimensions. Unlike traditional machining techniques that cut or subtract material, roll forming is a cost-effective solution for producing long lengths of high-volume components with uniform cross-sections.

The Role of Storage Racks in Warehousing

Storage racks are critical components in any warehousing and logistics setup. They facilitate the organization of inventory and enhance the overall efficiency of material handling. Storage racks must be strong, durable, and easy to assemble, making the role of the roll forming machine indispensable in their production. With the capacity to produce precise and robust beams, these machines ensure that storage systems can bear significant loads while maintaining structural integrity.

Key Features of Storage Rack and Beam Roll Forming Machines

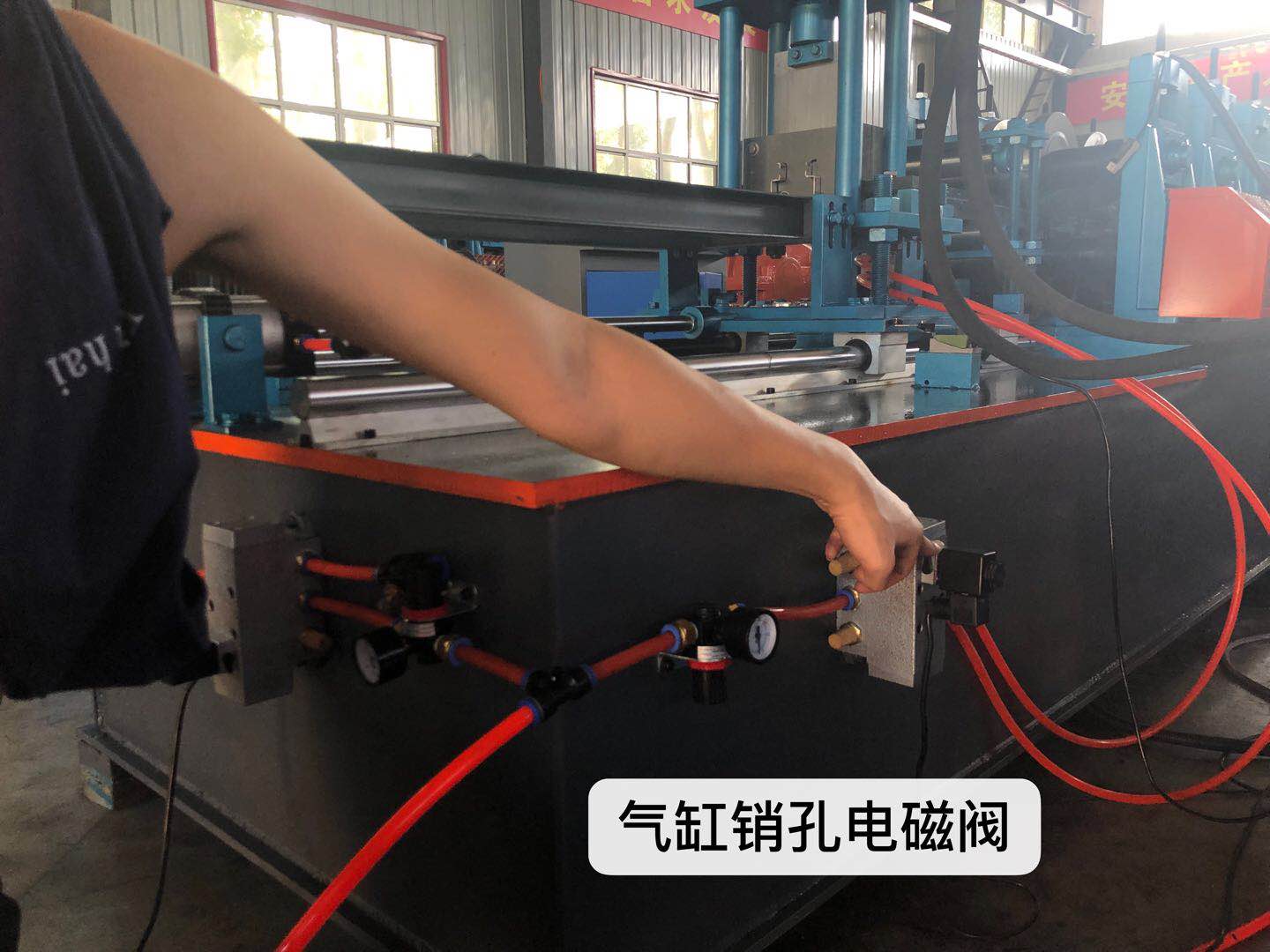

1. Automated Production Most modern roll forming machines operate with a high degree of automation. This not only reduces human error but also significantly increases production speed, allowing businesses to meet high demands without sacrificing quality.

2. Customization Different businesses have unique storage needs. Some roll forming machines can be custom-configured to produce diverse beam and rack designs, adapting to various warehouse specifications.

3. Material Versatility These machines can work with various materials, primarily steel, due to its strength and durability. Advanced models can also handle different thicknesses and metal types, making them versatile for different industrial applications.

4. Efficiency in Material Use Roll forming is often more material-efficient than other processes, allowing companies to make the most of their raw materials and reduce waste. This is crucial in reducing overall production costs and enhancing sustainability.

5. Quality Assurance With advanced technology and precision engineering, these machines ensure that the finished beams and racks meet stringent quality standards. This guarantees safety and reliability in storage solutions.

Advantages of Using Roll Forming Machines in Rack Production

The advantages of incorporating roll forming machines into storage rack production are manifold

- Cost-Effectiveness The efficiency of the roll forming process lowers production costs. Factoring in less material waste and reduced labor costs, manufacturers can enjoy higher profit margins.

- Scalability For businesses looking to grow, roll forming machines can easily scale production up or down based on demand. This flexibility is vital in today’s fast-paced market.

- Consistent Quality The automated and repetitive nature of roll forming ensures that each piece produced is uniform, contributing to the overall integrity of the storage system.

- Speed to Market With the ability to produce large quantities quickly, companies can respond to market demands swiftly, ensuring they can fulfill orders promptly and maintain customer satisfaction.

Conclusion

Storage rack and beam roll forming machines represent a significant advancement in manufacturing technology. Their ability to produce high-quality, customized, and efficient storage solutions plays a vital role in modern warehousing and logistics. With the growing emphasis on efficiency and sustainability in manufacturing practices, the relevance of these machines is likely to increase, making them an essential component for businesses looking to optimize their operations.

In summary, understanding the capabilities and benefits of storage rack and beam roll forming machines can help business owners make informed decisions that enhance productivity and profitability while also ensuring that their facilities are equipped to handle the demands of contemporary commerce.