The world of modern construction and engineering is continually evolving, driven by both innovation and the necessity for efficiency. At the heart of structural engineering and metal fabrication stands the storage beam forming machine, a critical piece of equipment that plays a pivotal role in the manufacturing process. Understanding its operation, benefits, and applications not only reflects the expertise of seasoned industry professionals but also builds trust and authority among those who seek to integrate this technology into their projects.

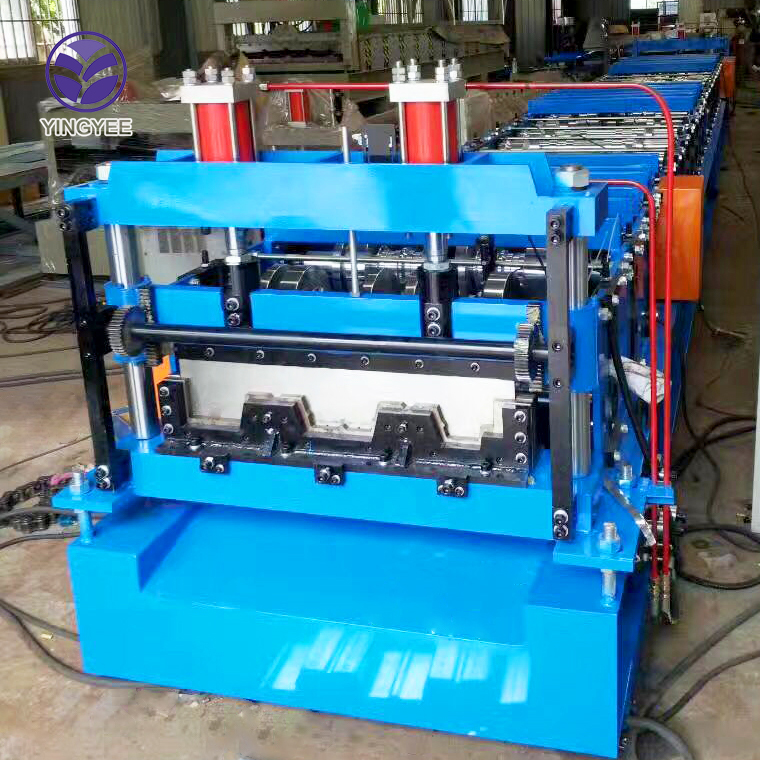

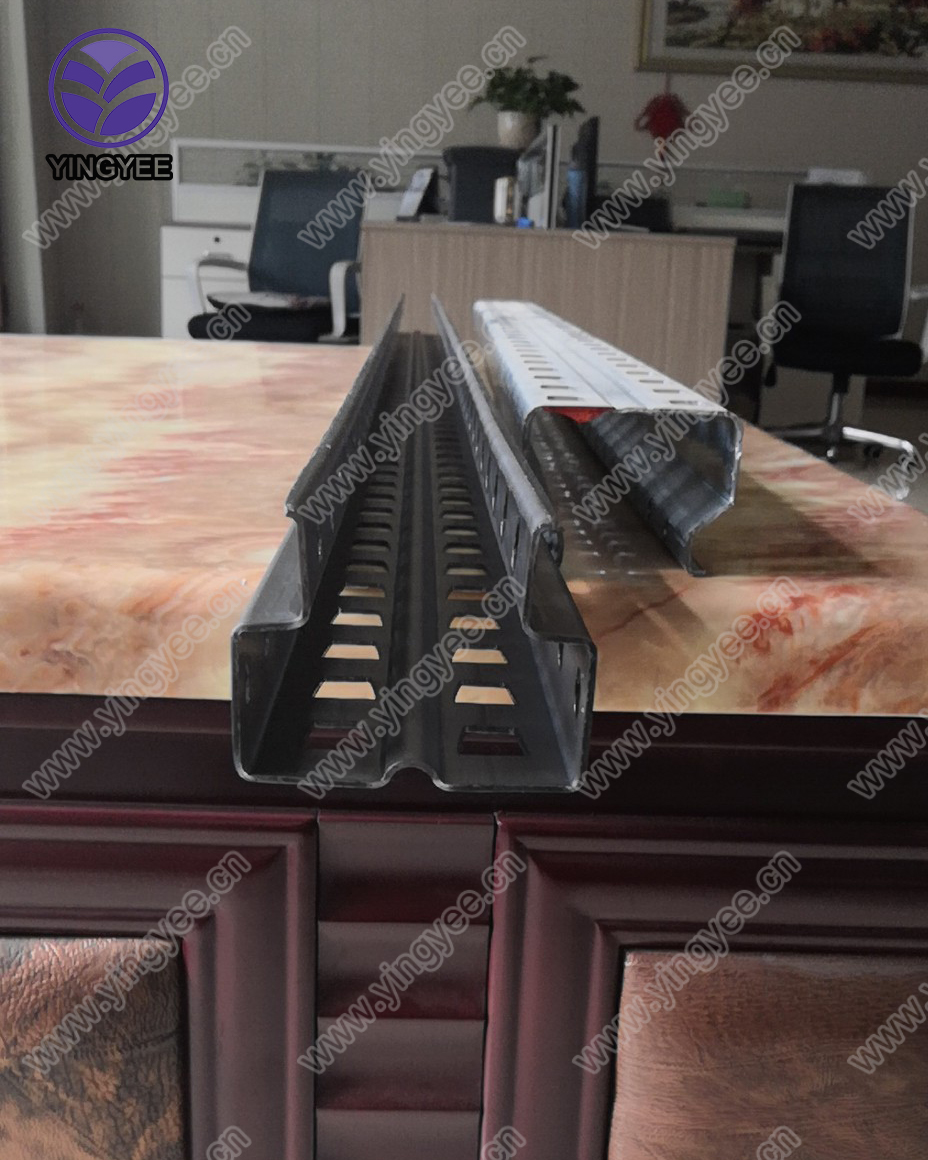

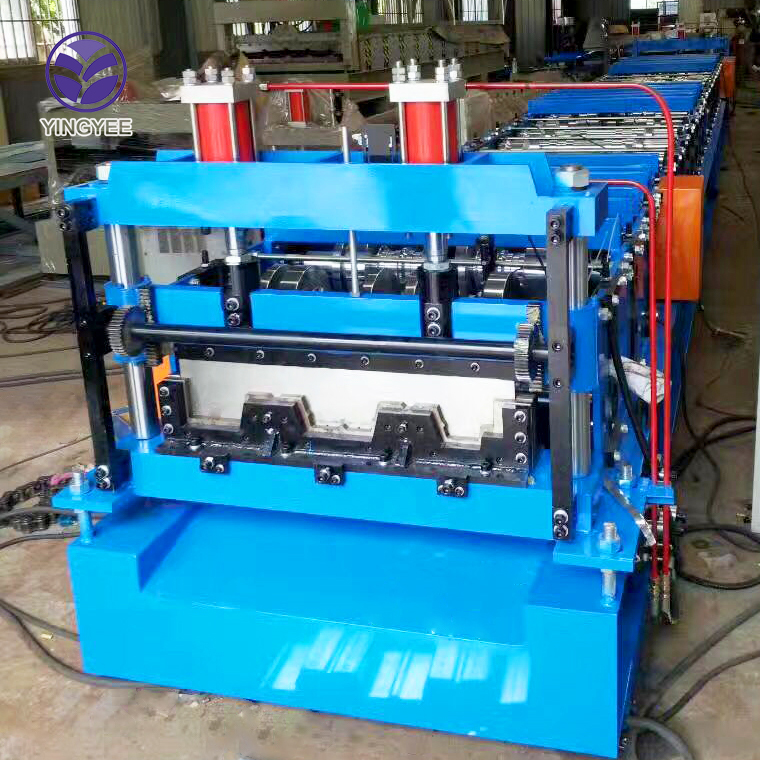

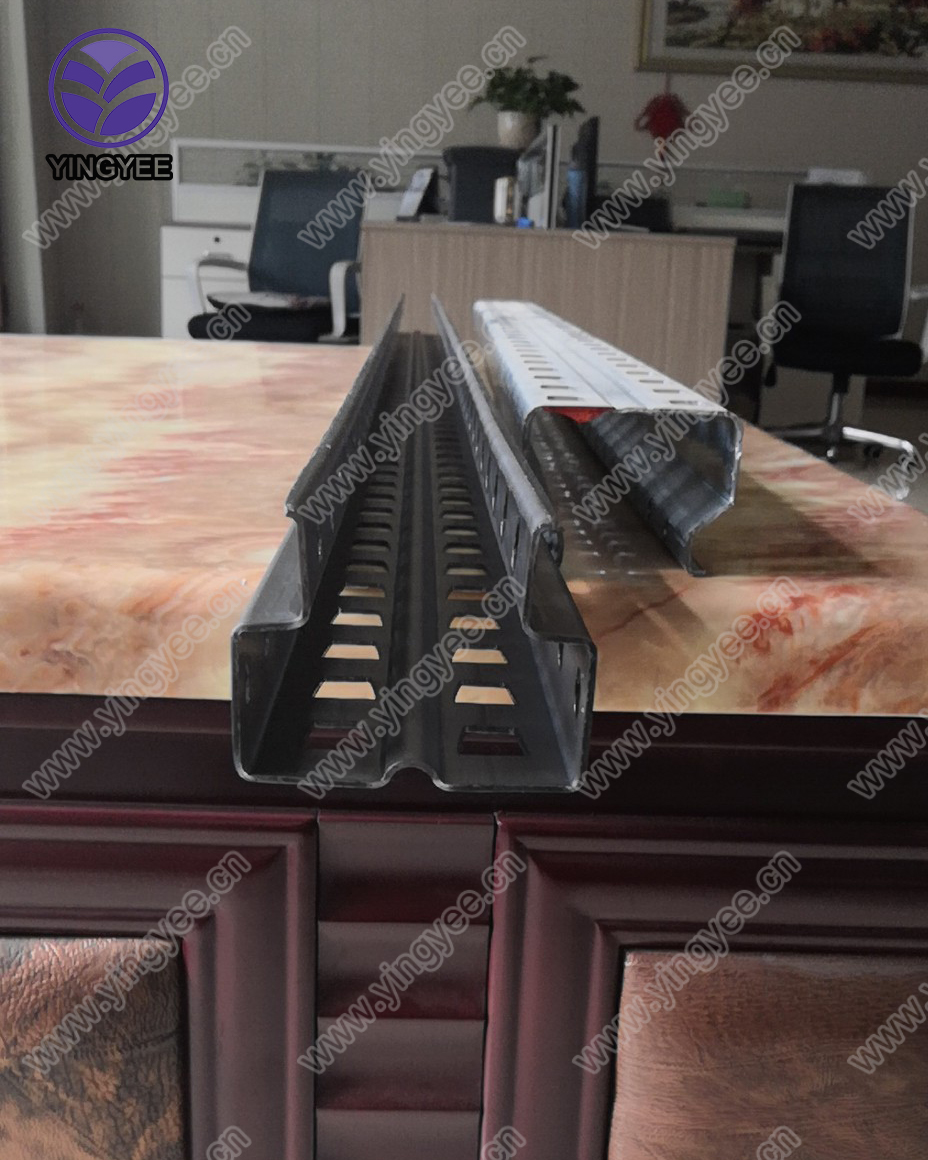

Storage beam forming machines revolutionize the way structural components are produced, ensuring not only precision but also enhancing the durability of the output products. These machines are specifically designed to create beams that form the backbone of storage systems, essential for both residential and commercial infrastructure. Unlike traditional methods that rely heavily on manual labor and often lead to inconsistencies, the machine's advanced mechanism allows for uniformity and strength, essential factors in construction projects demanding high safety standards.

From an expertise standpoint, operating these machines requires a comprehensive understanding of both the mechanical aspects of the machine itself and the material science behind the beams' durability. Professionals in this field are well-versed with the machine’s control systems, which often include computer numerical control (CNC) interfaces.

This allows for precise programming and reduces human error significantly. Moreover, understanding the metallurgical properties of the raw materials ensures that the beams formed meet specific load-bearing requirements.

In actual practice, expertise extends to maintaining and troubleshooting these machines, a skillset that further underscores a professional's authority in the industry. Regular maintenance ensures peak performance and longevity of the machinery, a critical aspect that directly impacts production timelines and costs. Maintenance crews are trained to detect early signs of wear and tear, ensuring that the machinery operates at optimal efficiency levels, ultimately reducing downtime.

The authoritative voice in this realm is often held by industry veterans and engineers who continuously research and innovate to improve the machine's functionality. Their contributions might include developing more efficient forming techniques or enhancing the machine's adaptability to different materials and project specifications. Such innovations can significantly reduce material waste, a crucial improvement in sustainable construction practices.

storage beam forming machine

Trustworthiness in this field is built through adherence to international standards and certifications, which the manufacturers of these machines often pursue. These standards ensure that the machine’s output meets the global benchmarks for safety and quality, which is paramount in construction projects worldwide. Companies that implement these machines in their production lines often highlight their compliance with such standards, thus reinforcing their commitment to safety and quality.

Moreover, case studies and real-world applications presented by reputable firms serve as testament to the storage beam forming machine's effectiveness. These documented instances demonstrate the machine's role in successful projects, ranging from skyscrapers to large-scale warehouses, detailing how it contributed to reducing construction time and costs while maintaining superior quality.

Furthermore, the integration of newer technologies such as IoT (Internet of Things) provides another layer of trust. These advancements enable real-time monitoring and diagnostics, giving operators the data needed to make informed decisions swiftly. Such capabilities allow for predictive maintenance, further minimizing downtime and enhancing productivity.

In conclusion, the storage beam forming machine stands as a testament to modern engineering's capabilities, showcasing the intricate balance between mechanical proficiency and material science knowledge. As projects grow more ambitious and timelines more demanding, these machines will continue to play a vital role, ensuring that structural integrity and dependability remain unwavering. For companies and professionals alike, investing in and mastering the use of such equipment is not merely a matter of staying competitive but is essential for leading the industry toward a more innovative and reliable future.