The Steel Strut Channel Roll Forming Machine An Essential Tool in Modern Manufacturing

In the realm of manufacturing and construction, efficiency and precision are paramount. One of the critical tools that have been developed to enhance these factors is the steel strut channel roll forming machine. This advanced piece of equipment is designed to produce high-quality steel strut channels that are widely used in various applications, such as construction, HVAC systems, and electrical conduit frameworks. In this article, we will explore the significance, components, and operational principles of the steel strut channel roll forming machine.

Significance of Steel Strut Channels

Steel strut channels are essential in providing structural support and stability in various construction projects. They serve as frameworks for mounting and securing components such as piping, ductwork, and electrical systems. The versatility of strut channels makes them a preferred choice for contractors and engineers. With the increasing demand for prefabricated construction materials, the need for efficient strut channel production has led to the widespread adoption of roll forming technology.

Components of the Roll Forming Machine

A steel strut channel roll forming machine consists of several key components that work together to produce the desired channel profile. These components include

1. Feeding System The feeding system is responsible for feeding the flat steel sheet into the machine. It ensures that the material is aligned correctly for subsequent processing.

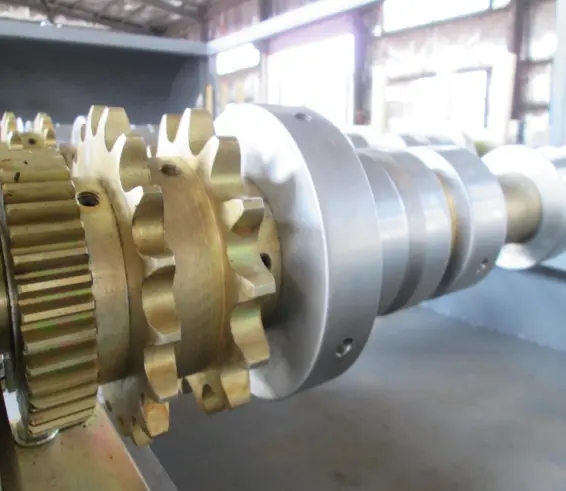

2. Roller Stations One of the core elements of the roll forming machine is the set of roller stations. Each station is equipped with specific rollers that progressively shape the steel sheet into the desired channel profile. The design of these rollers is critical as they determine the final dimensions and strength of the strut channel.

3. Cutting System The cutting system is responsible for trimming the formed strut channels to the specified lengths. This component can be equipped with different cutting mechanisms, including hydraulic and mechanical systems, to accommodate various production requirements.

4. Control System Modern roll forming machines are equipped with advanced control systems that enhance their functionality. These systems allow operators to monitor and adjust parameters such as speed, temperature (if applicable), and cutting length, ensuring precision and consistency in production.

5. Exit Section Once the strut channels are formed and cut, they are transported to the exit section, where they can be collected and packaged for delivery.

Operating Principles

The operation of a steel strut channel roll forming machine is relatively straightforward yet highly efficient. The process begins with the feeding of flat steel sheets into the machine. As the material progresses through the roller stations, it is gradually shaped into the desired channel profile through a series of bending and shaping operations.

The rollers in the machine are specifically designed to apply the necessary force and angular deformation to the steel, transforming it into a channel shape without compromising its structural integrity. Once the channel is formed, the cutting system ensures accurate lengths, preparing the final product for dispatch.

Benefits of Using Roll Forming Machines

The utilization of steel strut channel roll forming machines offers several significant advantages

1. Efficiency Roll forming machines are capable of producing large volumes of strut channels in a short period, making them highly efficient compared to traditional manufacturing methods.

2. Cost-Effectiveness By reducing material waste and maximizing production speed, roll forming can lead to substantial cost savings, particularly for high-demand projects.

3. Precision The advanced technology used in these machines ensures high accuracy in dimensions, reducing the need for additional processing or adjustments.

4. Versatility Roll forming machines can be customized to produce various channel sizes and shapes, catering to diverse applications and market needs.

5. Enhanced Structural Integrity The continuous shaping process of roll forming enhances the strength and durability of the produced channels, making them suitable for demanding structural applications.

Conclusion

The steel strut channel roll forming machine is an indispensable tool in modern manufacturing. Its ability to produce high-quality steel strut channels efficiently and cost-effectively has made it a vital component in the construction and manufacturing industries. As the demand for prefabricated materials continues to rise, the significance of such machines will only increase, driving innovation and advancements in production technology. Understanding the functionality and benefits of these machines is crucial for industry professionals aiming to maximize efficiency and quality in their projects.