Steel Silo Roll Forming Machine An Overview

In the realm of industrial manufacturing, the steel silo roll forming machine has emerged as a cornerstone for the efficient production of steel storage solutions. Steel silos, known for their durability and capacity to store a variety of bulk materials, are essential in industries such as agriculture, food production, and construction. The roll forming machine plays a critical role in the fabrication of these silos, allowing for mass production that ensures consistent quality and structural integrity.

The Process of Roll Forming

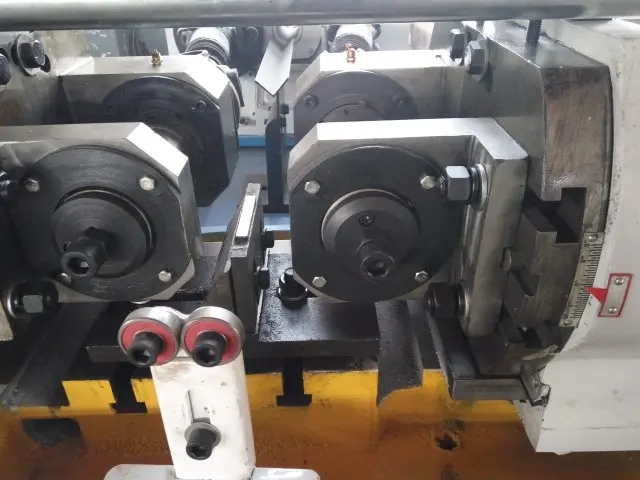

Roll forming is a continuous bending process in which a long strip of sheet metal is shaped into the desired cross-section using a series of rollers. The steel silo roll forming machine consists of several pairs of rollers that incrementally form the steel sheet into the cylindrical shape required for silos. The process begins with feeding flat steel sheets into the machine, where they are guided through various pairs of rollers. Each roller applies pressure, bending the steel further until the final shape is achieved.

The efficiency of this process is one of its key advantages

. Compared to traditional methods, roll forming minimizes waste and reduces production time. The machine can produce an entire sheet of silo material in a single pass, leading to faster turnaround times for manufacturers.Customization and Versatility

Steel silo roll forming machines are designed with versatility in mind. They can be customized to produce silos of various sizes and dimensions, catering to the specific needs of different industries. This customization is crucial as storage requirements vary dramatically; a farm may need smaller silos for grains, while a construction site might require larger units for materials like cement or sand.

Additionally, the machines can be adjusted to accommodate different steel thicknesses and grades, ensuring that the final product meets the necessary strength and durability specifications. This adaptability not only improves product quality but also enhances the machine's usability across different applications.

Integration with Automation

Modern steel silo roll forming machines are increasingly integrated with automation technology, enabling manufacturers to improve efficiency and reduce labor costs. Automated systems can handle tasks such as material feeding, cutting, and quality inspection, ensuring that production runs smoothly and consistently. This advanced technology also allows for real-time monitoring and data collection, facilitating better production management and maintenance scheduling.

Conclusion

The steel silo roll forming machine is a vital tool in the production of durable and efficient storage solutions. Its ability to produce customized silos quickly and efficiently makes it a valuable asset across various industries. As technology continues to evolve, the integration of automation will further enhance the capabilities of these machines, driving innovation and improving the overall quality of steel silos. For manufacturers looking to optimize their production processes and meet the growing demand for bulk storage solutions, investing in a steel silo roll forming machine is a strategic decision that promises significant returns.