The Steel Rods Truss Mesh Machine Revolutionizing Construction

In the ever-evolving landscape of the construction industry, the demand for efficiency, durability, and cost-effectiveness is paramount. One of the innovations that have emerged to meet these needs is the steel rods truss mesh machine. This sophisticated piece of equipment is designed to streamline the process of creating truss meshes, which are integral to a variety of construction applications, from residential buildings to large-scale industrial projects.

Understanding Truss Meshes

Before delving into the specifics of the truss mesh machine, it's essential to understand what truss meshes are. These structures consist of interconnected steel rods arranged in a way that distributes loads efficiently. The design of a truss mesh capitalizes on the strength of steel while minimizing the amount of material required. This not only reduces the weight of the structure but also enhances its durability. Truss meshes are widely used in floor systems, roofing, and bridges due to their ability to provide high resistance to both tensile and compressive forces.

The Role of the Steel Rods Truss Mesh Machine

The steel rods truss mesh machine automates the process of creating these intricate structures, significantly improving production speed and consistency. Traditionally, fabricating truss meshes involved manual labor, which could lead to inconsistencies and delays. With the introduction of this machine, the industry is witnessing a shift toward greater automation and precision.

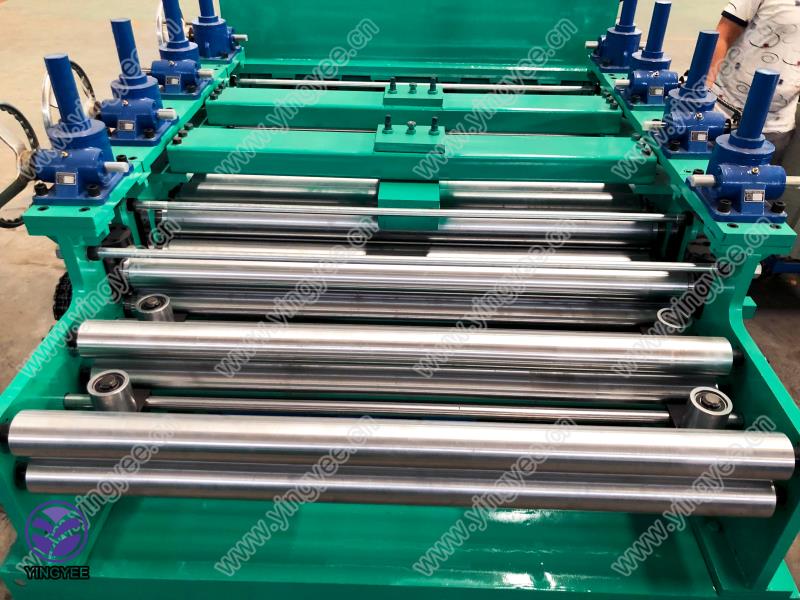

The machine operates by feeding steel rods into a series of automated processes that cut, bend, and weld these materials into the desired truss configurations. Operators can easily input designs through a user-friendly interface, allowing for customization based on specific project requirements. This flexibility ensures that builders can achieve unique designs without sacrificing time or quality.

Benefits of the Steel Rods Truss Mesh Machine

1. Increased Efficiency One of the most significant advantages of using a truss mesh machine is the increase in productivity. The automated process can drastically reduce the time required to produce truss meshes compared to manual methods. This efficiency enables construction projects to stay on schedule, which is crucial in a competitive market.

2. Enhanced Precision Accuracy is vital in construction, and the steel rods truss mesh machine ensures that every piece is manufactured according to exact specifications. With precise cutting and welding capabilities, the likelihood of errors is minimized, resulting in higher quality outputs.

3. Cost-Effectiveness While the initial investment in a steel rods truss mesh machine may be considerable, the long-term savings are substantial. The reduced labor costs, coupled with the machine's ability to produce high-quality products quickly, can lead to significant cost reductions over time. Furthermore, the minimized waste from accurate cuts and designs contributes to overall savings.

4. Improved Safety Automating the manufacturing process reduces the amount of manual labor required, thereby enhancing workplace safety. Operators are less exposed to the risks associated with traditional manufacturing methods, as many of the hazardous tasks are carried out by the machine.

5. Versatility The machine can accommodate various designs and sizes, making it suitable for a wide range of projects. Whether it's residential constructions or large commercial buildings, the adaptability of the steel rods truss mesh machine allows builders to tackle diverse challenges with ease.

Conclusion

The steel rods truss mesh machine represents a significant advancement in the construction industry. By enhancing efficiency, precision, and safety, it helps builders meet the demands of modern construction while maintaining high standards of quality. As the industry continues to evolve, staying up-to-date with innovations like this machine will be essential for companies aiming to remain competitive. As we move forward, the integration of advanced machinery will not only change how we build but also contribute to more sustainable and resilient construction practices, paving the way for a brighter future in the industry.