The Evolution of Steel Rods in Truss Mesh Machines

In the ever-evolving landscape of construction and manufacturing, steel rods have emerged as a fundamental component in the design and implementation of truss mesh machines. These machines play a crucial role in fabricating truss structures, which are widely used in various applications, including bridges, roofs, and industrial buildings. This article explores the significance of steel rods in truss mesh technology, highlighting their benefits, applications, and recent advancements in machine design.

Understanding Truss Mesh Machines

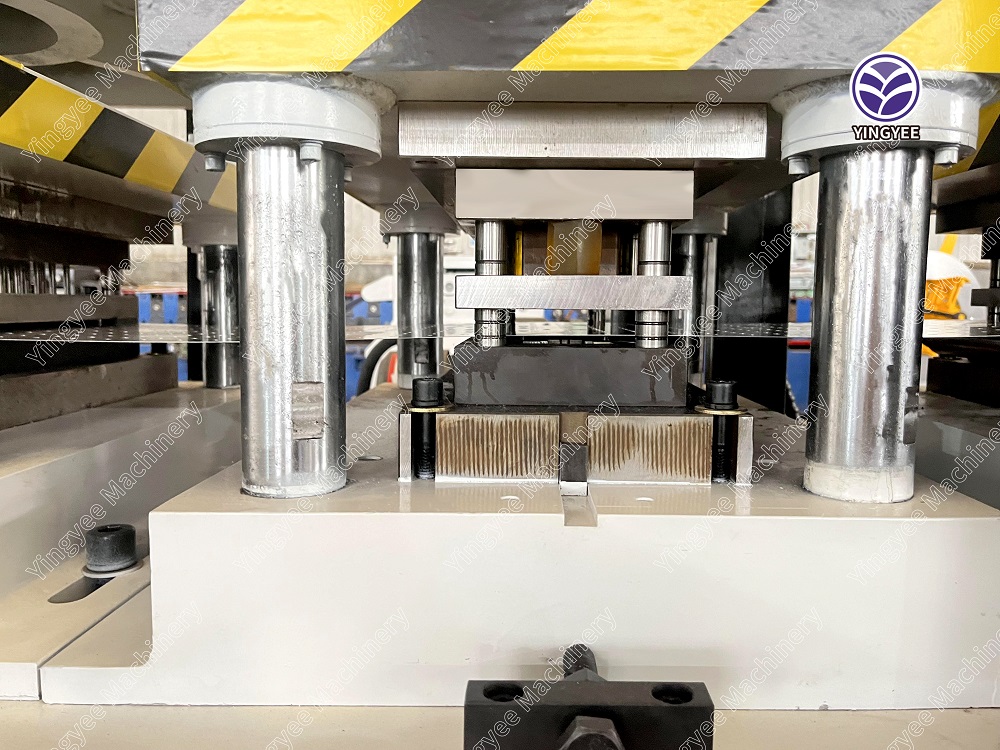

Truss mesh machines are specialized equipment designed to produce truss meshes, which are grid-like frameworks constructed from rods or bars. These frameworks provide structural support and load distribution, making them essential in modern construction. The primary function of a truss mesh machine is to automate the process of bending, cutting, and welding steel rods into a predefined mesh pattern, increasing efficiency and precision in construction projects.

The Role of Steel Rods

Steel rods serve as the backbone of truss mesh structures. Typically crafted from high-strength steel, these rods exhibit exceptional tensile strength, durability, and resistance to deformation. This makes them ideal for bearing heavy loads and enduring various environmental conditions. The primary advantages of using steel rods in truss meshes include

1. Strength and Stability Steel rods provide the necessary structural integrity to withstand external forces, such as wind, seismic activity, and dynamic loads. Their robustness ensures that the truss structures remain stable and reliable over time.

2. Versatility Steel rods can be manufactured in various diameters and grades, allowing for customization based on specific engineering requirements. This versatility enables architects and engineers to design truss systems tailored to unique project needs.

3. Cost-Effectiveness While the initial cost of steel rods may be higher than other materials, their longevity and low maintenance requirements often result in reduced overall project costs. This makes them an economical choice for large-scale construction projects.

4. Ease of Fabrication The design of truss mesh machines facilitates the rapid production of steel rods into mesh patterns. Automated processes reduce labor costs and human error, resulting in consistent quality and faster turnaround times.

Recent Advancements in Truss Mesh Technology

As technology continues to advance, so too does the design and functionality of truss mesh machines. Recent innovations include enhancements in automation, material handling, and computer-aided design (CAD) integration. These advancements have significantly improved the efficiency of truss production processes.

1. Automation Modern truss mesh machines now incorporate advanced robotics and automation systems that minimize the need for manual intervention. Automated feeding systems ensure a continuous supply of steel rods, while robotic arms handle bending and welding with unparalleled precision.

2. CAD Integration The incorporation of CAD software allows for precise design specifications and simulation of truss meshes before production. This technology enables engineers to visualize the truss structure, optimizing the design for strength and load distribution.

3. Improved Safety Features With the rise of automated machinery, safety has become a critical focus in the design of truss mesh machines. Enhanced safety features, including emergency stop systems and protective barriers, ensure a safer working environment.

4. Sustainability Initiatives There is an increasing emphasis on sustainable construction methods, leading to the development of eco-friendly steel rods, which are made from recycled materials. This aligns with global efforts to reduce carbon footprints and promote responsible resource use.

Conclusion

The integration of steel rods in truss mesh machines has revolutionized the construction industry, offering efficiency, strength, and versatility. As advancements in technology continue to emerge, the capabilities of truss mesh machines will undoubtedly expand, further enhancing the potential for innovative structural designs. The ongoing exploration of sustainable practices in the use of steel will also contribute to a more environmentally friendly construction landscape. With solid foundational materials and cutting-edge machinery, the future of construction looks promising.