Steel Purlin Roll Forming Machine Revolutionizing Construction

In the world of modern construction, efficiency and precision are paramount. One technology that has significantly contributed to these aspects is the steel purlin roll forming machine. This machine plays an essential role in the production of steel purlins, which are key components in framing systems for various structures, including warehouses, factories, and commercial buildings. This article explores the design, functionality, and advantages of steel purlin roll forming machines.

Understanding Steel Purlins

Steel purlins are horizontal structural members used to support roof and wall sheeting in buildings. They provide critical support, enabling the distribution of loads from the roof to the vertical structure. Typically made from galvanized steel or other high-strength alloys, purlins are favored for their durability, strength, and resistance to environmental factors.

The demand for steel purlins has surged due to the growth of the construction industry, driven by the need for faster and more economical building solutions. This has led to the development of advanced manufacturing technologies, including the highly efficient steel purlin roll forming machine.

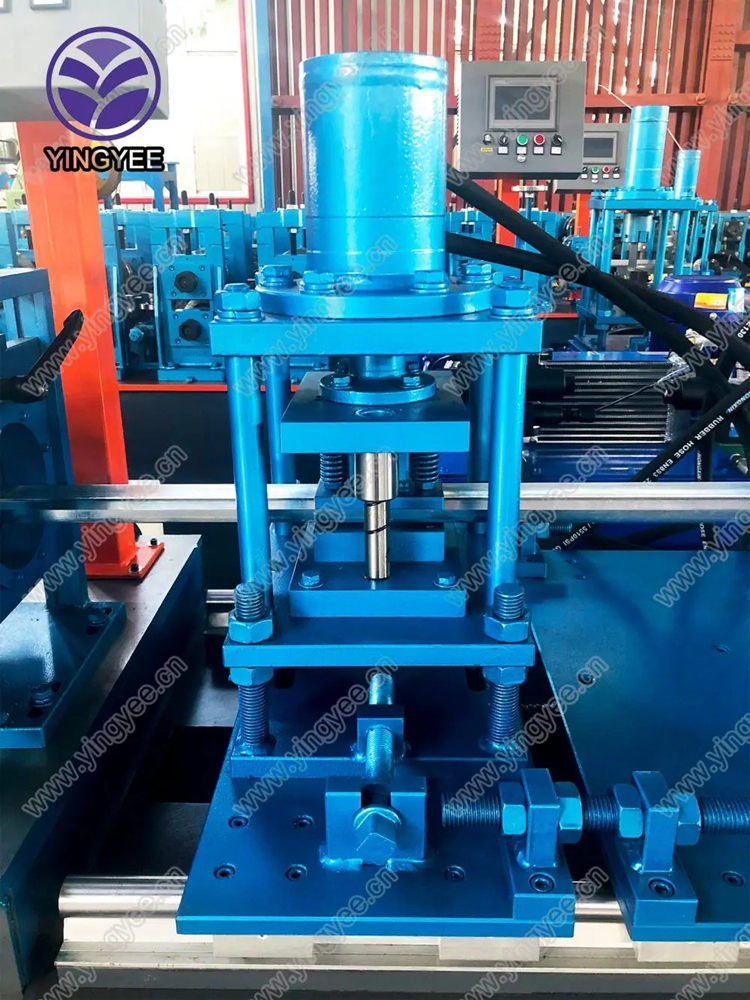

How a Steel Purlin Roll Forming Machine Works

A steel purlin roll forming machine is designed to produce purlins of various sizes and shapes continuously. The process begins with flat steel coils, which are fed into the machine. As the steel passes through a series of rollers, it is progressively shaped into the desired profile.

The process can be broken down into several key steps

1. Coil Loading Steel coils are loaded onto the machine. These coils are often pre-treated to enhance their mechanical properties and corrosion resistance.

2. Uncoiling The coil is unwound, and the flat sheet is guided into the roll forming section.

3. Roll Forming This critical step involves a series of rollers that gradually bend the flat steel into the desired shape. The design of the rollers ensures that the material is shaped uniformly, resulting in high accuracy.

5. Stacking and Packaging Finally, the finished purlins are stacked and prepared for transportation or further processing.

Many modern machines incorporate automation technologies to enhance efficiency and reduce labor costs. These machines can be programmed to produce different purlin sizes and shapes with minimal downtime, providing significant flexibility to manufacturers.

Advantages of Steel Purlin Roll Forming Machines

1. High Efficiency Roll forming is a continuous process, allowing for high production rates, which is crucial for meeting the demands of large-scale construction projects.

2. Cost-Effectiveness By maximizing material utilization and reducing waste, the roll forming process lowers production costs. Moreover, these machines often require less labor compared to traditional manufacturing methods.

3. Customization Steel purlin roll forming machines can be easily adjusted to produce different profiles and sizes, making them suitable for various applications and client specifications.

4. Quality Control The precision of roll forming lends itself to consistent quality. Automated systems ensure that each purlin meets rigorous standards and tolerances.

5. Durability and Strength The resulting steel purlins exhibit excellent mechanical properties, providing reliable support for structures and an extended service life under various load conditions.

Conclusion

The steel purlin roll forming machine stands at the forefront of modern construction technologies, optimizing the fabrication of essential structural components. As the construction industry continues to evolve, embracing automation and precision engineering, the role of such machines will only grow significance. From their efficient production methods to their customizable features, steel purlin roll forming machines offer a viable solution for builders looking to streamline processes while maintaining high standards of quality. Embracing this innovative technology not only enhances productivity but also reinforces the foundations of future construction endeavors.