When it comes to modern construction and architectural marvels, the role of machinery in creating the backbone of structures cannot be understated. One such innovation that has revolutionized the building industry is the steel long span roof roll forming machine. This machine is pivotal for projects requiring extensive and sturdy roofing solutions. With the growing demands for efficient and cost-effective construction methods, understanding the nuances of this technology is crucial for builders and architects alike.

The steel long span roof roll forming machine is an engineering marvel designed to manufacture long stretching roof panels for expansive buildings such as warehouses, factories, and sports arenas. Its primary function is to produce roofing sheets that are not just structurally sound but also aesthetically pleasing and durable. One of the key elements that set this machine apart is its capability to produce sheets of varying lengths and profiles, accommodating the bespoke needs of different projects.

For construction experts, the reliability and efficiency of the steel long span roof roll forming machine are paramount. Based on extensive hands-on experience with the machine, professionals recognize that its effectiveness stems from its advanced design and automation capabilities. The machine incorporates precision engineering techniques that ensure each roofing panel is produced to exact specifications, minimizing wastage and reducing the overall project timelines.

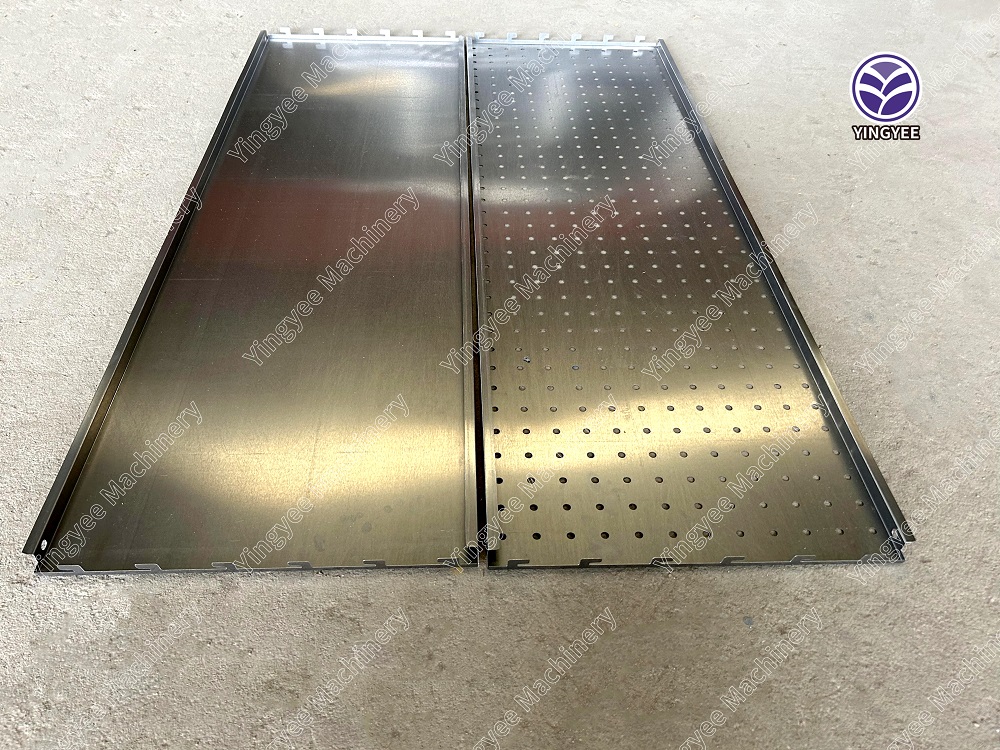

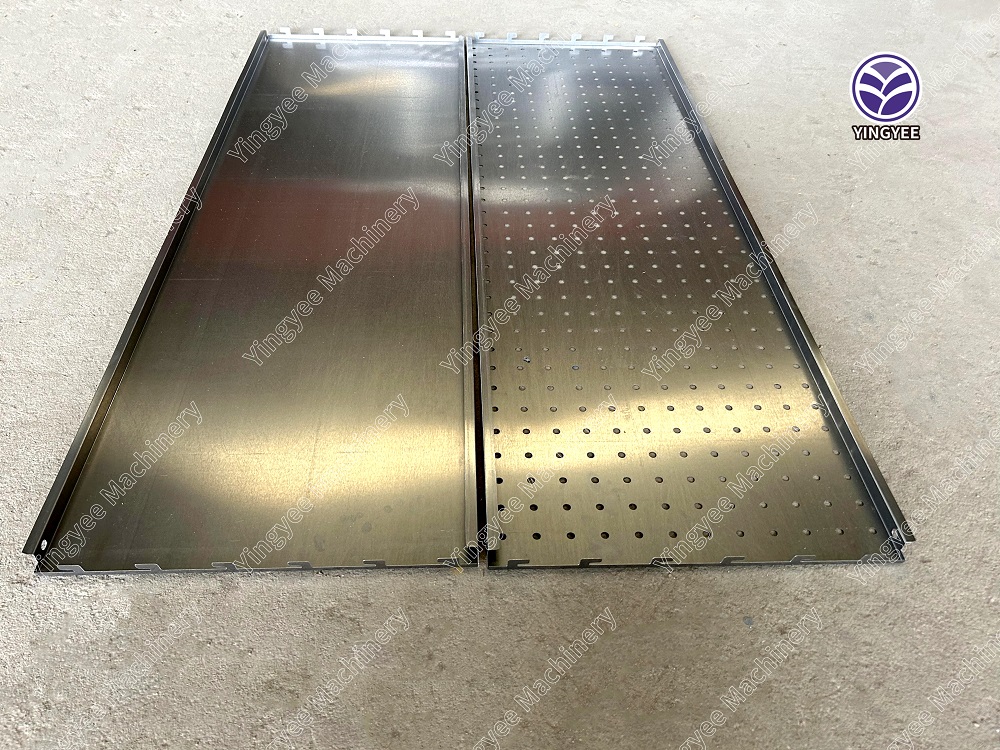

A deeper dive into the mechanics of the steel long span roof roll forming machine reveals a sophisticated interplay of components that work in harmony. The machine typically comprises a decoiler, feeding guide,

roll forming system, cutting device, and an auto stacker. Each of these components is crafted with high-grade materials, ensuring longevity and consistent performance. The roll forming system, in particular, is the heart of the machine, utilizing a series of rollers to shape the metal into the desired profile.

steel long span roof roll forming machine

Expertise in operating this machinery is essential for harnessing its full potential. Skilled operators leverage advanced control systems that manage every aspect of the forming process, from speed adjustments to profile changes, ensuring optimal output quality. Moreover, regular maintenance and calibration are critical, as they uphold the precision of the machine's output and extend its operational life. Professionals often employ a preventive maintenance schedule that focuses on key areas such as lubrication, alignment checks, and system diagnostics.

In terms of authoritativeness, the steel long span roof roll forming machine is backed by an extensive body of research and development. Leading manufacturers invest heavily in innovation, continually enhancing the technology to meet evolving industry standards and environmental regulations. Many of these machines are now equipped with eco-friendly features that reduce energy consumption and minimize the carbon footprint of construction projects.

Trustworthiness is another core attribute of this machine, achieved through stringent quality control measures implemented by manufacturers. Each machine undergoes rigorous testing under various conditions to validate its performance and safety standards. Additionally, the availability of comprehensive customer support services further instills confidence among users, as they know they can rely on expert assistance whenever technical issues arise.

In conclusion, the steel long span roof roll forming machine is an indispensable tool in modern large-scale construction. It exemplifies the blend of experience, expertise, authoritativeness, and trustworthiness required to support the dynamic needs of the industry. For professionals seeking to elevate their construction projects, investing in this machine not only ensures superior roofing quality but also contributes to the efficiency and sustainability of building practices. Through continuous improvement and innovation, the machine remains at the forefront of architectural advancements, setting a benchmark for quality and performance in roofing solutions.