Understanding Steel Long Span Roof Roll Forming Machines

In the realm of construction and architecture, steel has long been heralded as one of the most versatile and durable materials available. Its high strength-to-weight ratio and recyclability make it an ideal choice for various structural applications, particularly in roofing solutions. Steel long span roof roll forming machines are essential tools in this sector, enabling manufacturers to produce high-quality steel roofing components efficiently and effectively.

The Importance of Long Span Roof Solutions

Long span roofing systems are crucial for large commercial buildings, warehouses, and industrial facilities. Unlike traditional roofing systems that require more frequent supports, long span roofs can cover larger areas without the need for intermediate columns. This design flexibility allows for more open interior spaces, which is particularly beneficial for operations that require unobstructed floor areas, such as manufacturing plants and sports facilities.

What is a Steel Long Span Roof Roll Forming Machine?

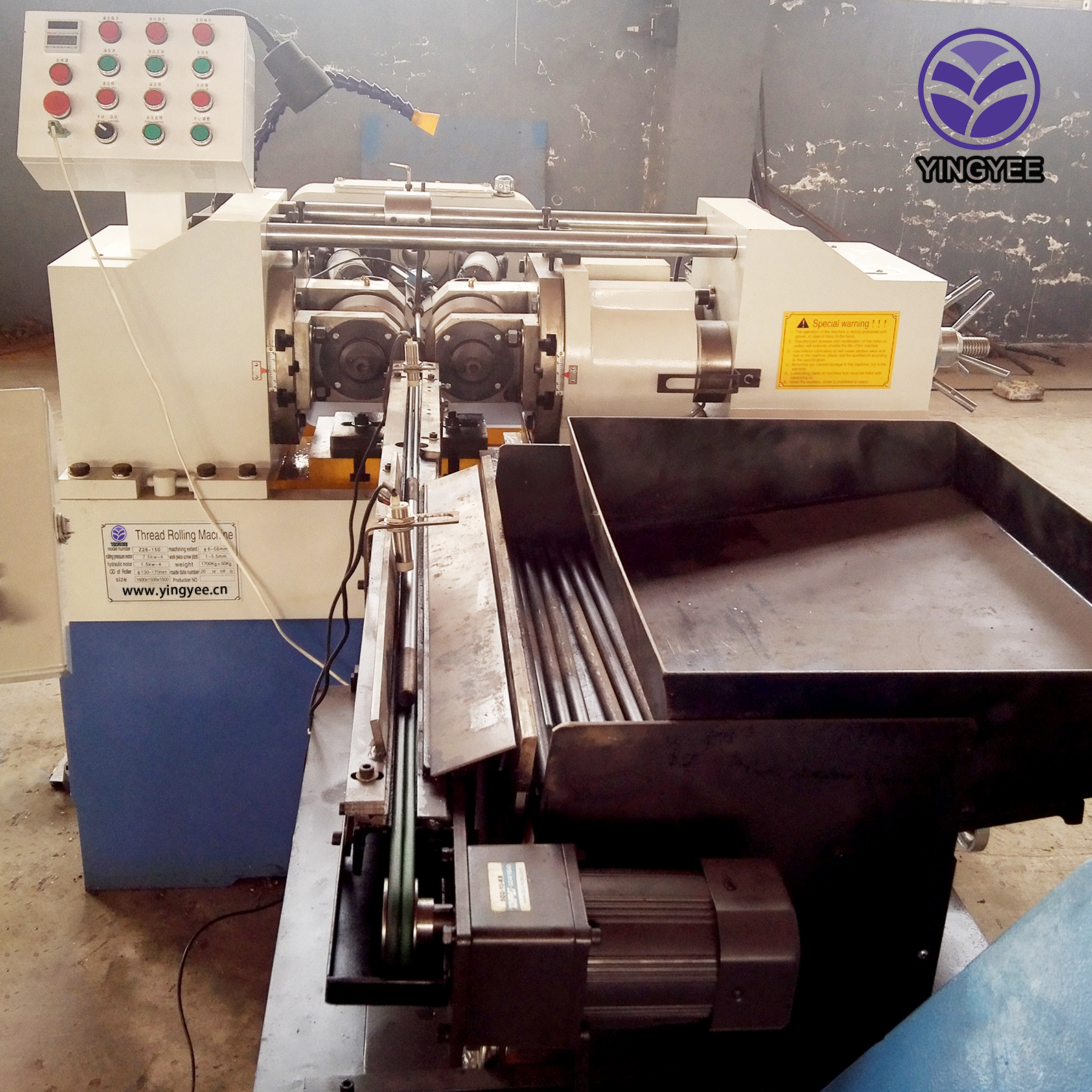

A steel long span roof roll forming machine is specialized equipment designed for shaping and forming metal sheets into various profiles needed for roofing applications. These machines operate through a continuous process where a flat metal sheet is fed into a series of rollers that gradually reshape it into a specific profile, such as trapezoidal or sinusoidal shapes commonly used in roofing.

The roll forming process is highly automated and can produce long lengths of steel roofing panels at a high throughput, making it an efficient solution for large projects. The end products are characterized by their strength, durability, and resistance to weather conditions, which are critical properties for roofing materials.

Key Features of Roll Forming Machines

1. High Precision Modern steel long span roof roll forming machines are equipped with advanced technology that allows for precise control over the dimensions and profiles of the finished products. This precision ensures that the components fit perfectly during installation, reducing waste and enhancing structural integrity.

2. Versatility These machines can be adjusted to accommodate different profiles and thicknesses of steel, enabling manufacturers to diversify their product offerings. This adaptability is vital in meeting the varying demands of construction projects.

3. Automated Control Systems The incorporation of PLC (Programmable Logic Controller) systems in modern roll forming machines enables automatic monitoring and control of the forming process. This feature enhances operational efficiency and reduces the likelihood of human errors.

4. Durability and Reliability Steel long span roof roll forming machines are built to withstand the rigorous conditions of continuous operation. They are typically made from high-quality materials and are designed for longevity, delivering significant returns on investment for manufacturers.

Benefits of Using Steel Long Span Roof Roll Forming Machines

1. Cost Efficiency By producing roofing panels in-house, manufacturers can significantly reduce material costs and labor expenses. The continuous production process minimizes downtime and maximizes productivity.

2. Customization Capabilities Manufacturers can tailor the roofing panels according to specific client requirements, including varying lengths, widths, and profiles. This level of customization is rarely possible with pre-formed materials.

3. Sustainability Many steel manufacturers are now adopting environmentally friendly practices, including the use of recycled steel and energy-efficient production processes. Roll forming also generates less waste compared to other forming methods.

4. Fast Production Times The automated nature of roll forming machines allows for rapid production cycles, enabling timely project completion. This speed is particularly valuable in the fast-paced construction industry.

Conclusion

Steel long span roof roll forming machines represent a significant advancement in the manufacturing of roofing materials. Their ability to produce high-quality, precise, and diverse steel profiles makes them indispensable in the construction industry. As buildings evolve to meet modern architectural demands, these machines will continue to play a pivotal role in facilitating efficient, sustainable, and innovative roofing solutions. Through technological advancements and increased customization capabilities, manufacturers can not only enhance their operational efficiencies but also meet the growing expectations of their clients. The future of roofing solutions lies in the capabilities of these sophisticated roll forming machines.