The Steel Frame Roll Forming Machine Revolutionizing Construction

In the modern construction industry, efficiency and precision are paramount. One innovative solution that has gained significant traction is the steel frame roll forming machine. This advanced equipment transforms flat steel sheets into precisely engineered frames, which play a crucial role in the structural integrity of buildings.

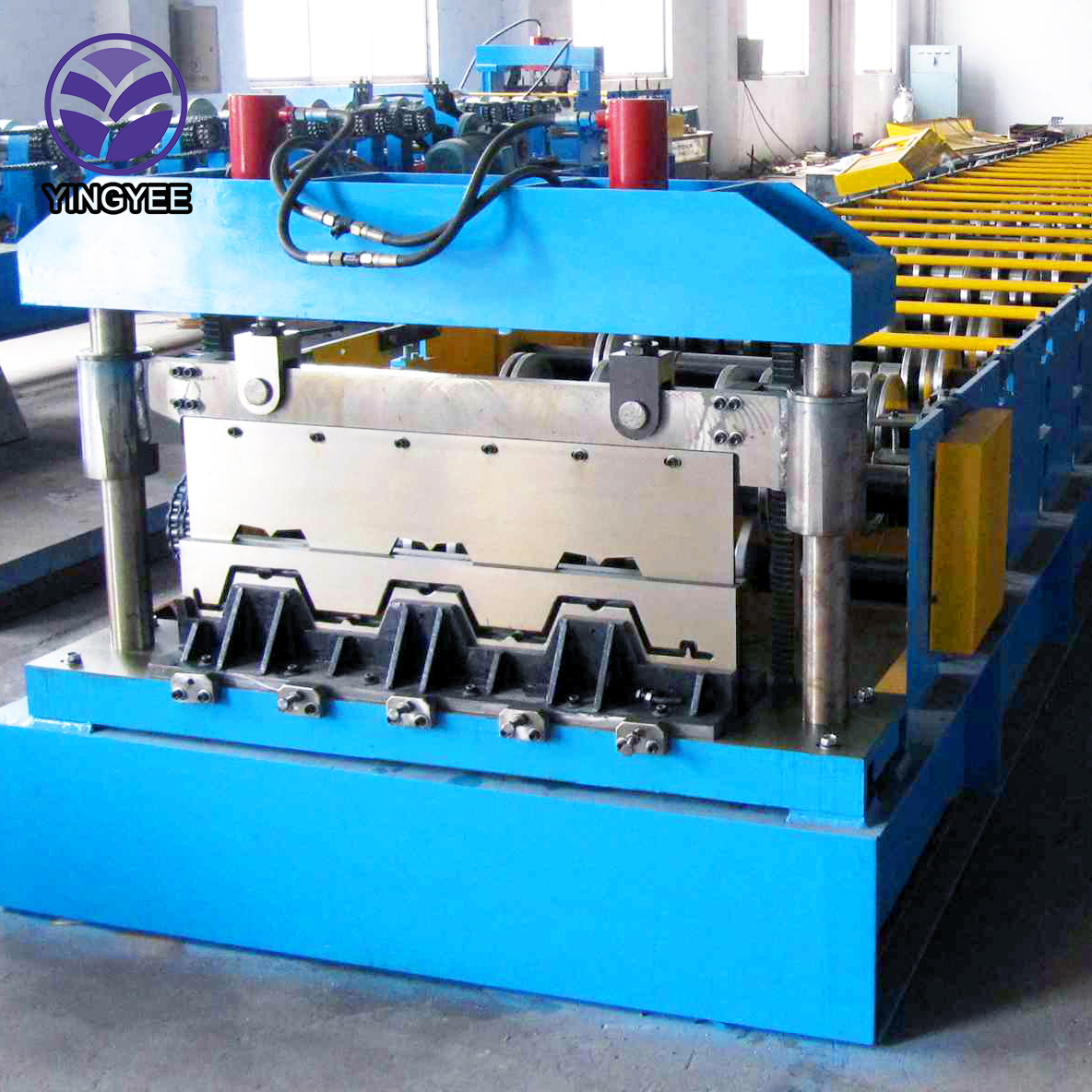

At its core, the steel frame roll forming machine operates by feeding flat strips of steel into a series of rollers. These rollers gradually shape the steel into a desired profile through a continuous process. The beauty of this technology lies in its ability to produce high-quality frames consistently, reducing material waste and minimizing labor costs. With the ability to customize profiles, manufacturers can cater to specific project requirements, ensuring that each steel component meets stringent industry standards.

One of the most significant advantages of using a steel frame roll forming machine is the speed of production. Traditional framing methods can be time-consuming, often leading to delays in project timelines. In contrast, roll forming allows for rapid assembly, enabling construction teams to complete projects more efficiently. The streamlined process also means that multiple components can be produced simultaneously, further enhancing productivity.

Additionally, steel frames produced via roll forming are known for their strength and durability. Steel, as a material, is inherently resistant to various environmental factors such as fire, pests, and rot. When formed into a frame, it provides a robust foundation that can withstand heavy loads, making it ideal for modern buildings. This aspect is especially important as the industry moves towards designing structures that can endure extreme weather conditions and seismic activities.

Moreover, the sustainability aspect of steel frame roll forming cannot be overlooked. Steel is infinitely recyclable, and using it in construction promotes a circular economy. By adopting roll forming processes, manufacturers can reduce waste and energy consumption, aligning with global initiatives for sustainable building practices.

In conclusion, the steel frame roll forming machine is transforming the landscape of the construction industry. Its ability to produce high-quality, customizable frames at a rapid pace while ensuring sustainability is unmatched. As architects and builders continue to seek efficient solutions for modern construction challenges, the roll forming technology stands out as a cornerstone of innovation, promising a future where buildings are not only stronger but also environmentally friendly.