The Steel Frame CZ Purlin Roll Forming Machine A Comprehensive Overview

In the modern construction industry, efficient and cost-effective production methods are paramount. One such advancement is the steel frame CZ purlin roll forming machine, a critical piece of equipment designed to manufacture C and Z purlins used in a variety of structures, including warehouses, factories, and high-rise buildings. This article explores the significance, operation, and benefits of using a roll forming machine for producing CZ purlins.

Understanding CZ Purlins

Purlins are horizontal structural members that support roofing and wall sheeting in buildings. The designation of C and Z refers to the shape of the steel profiles. C purlins are typically used for rafters and supports, while Z purlins often serve as girts and are ideal for buildings with both vertical and horizontal frames. The ability to form these shapes efficiently is crucial for maintaining structural integrity while optimizing material usage.

The Role of the Roll Forming Machine

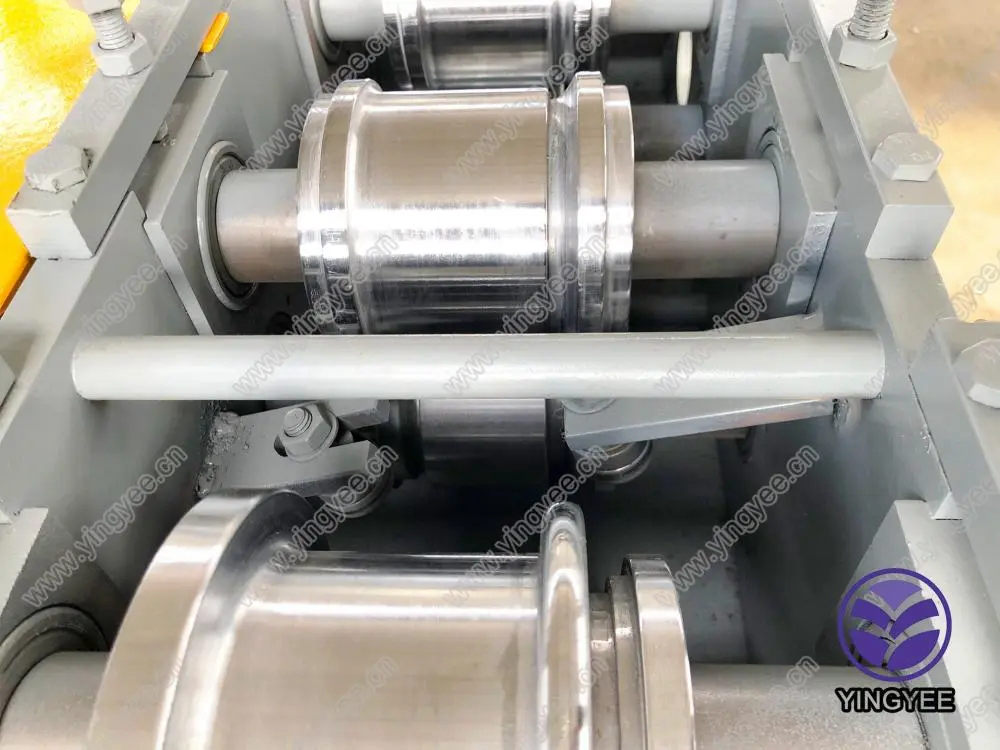

A steel frame CZ purlin roll forming machine automates the manufacturing process by continuously shaping steel coils into the desired profiles using a series of rollers. This machinery is designed for high productivity, allowing manufacturers to produce large quantities of purlins quickly and accurately. The process begins with the feeding of a flat steel strip into the roll forming machine, where it passes through various stations. Each station molds the strip progressively, giving it a defined shape by bending the steel along specified contours.

Key Features of the Roll Forming Process

1. Customizable Designs One of the primary benefits of using a roll forming machine is the ability to customize purlin dimensions and thickness to meet specific project needs. Operators can adjust the machine settings to accommodate different specifications, making it ideal for a range of construction applications.

2. High Efficiency Roll forming machines are known for their speed and efficiency. They can produce a significant number of purlins in a short amount of time, reducing labor costs and increasing overall productivity.

3. Material Savings The continuous nature of the roll forming process minimizes waste. By optimizing the production layout and precision forming, manufacturers can ensure that raw materials are utilized effectively, leading to cost savings and a reduced environmental footprint.

4. Durability and Strength The structural integrity of the purlins produced by these machines is enhanced through the controlled rolling process. The resulting steel profiles are sturdy and capable of bearing heavy loads, making them suitable for various applications.

Applications of CZ Purlins

The CZ purlins produced by roll forming machines are prominently used in commercial and industrial construction projects. They are essential components in building frameworks, offering strong support for roof trusses and wall sheathing. Additionally, these purlins are widely used in the construction of pre-engineered buildings, where rapid assembly and high strength are critical factors.

Purlins also find applications in running frames for solar panels, contributing to the renewable energy sector's growth. Their versatility extends beyond typical construction uses; they are effective in agricultural buildings, storage facilities, and even in modular construction.

Conclusion

The steel frame CZ purlin roll forming machine represents a significant technological advancement in the construction industry. By automating the production of purlins, these machines enable manufacturers to produce high-quality structural components efficiently and cost-effectively. With the ability to customize specifications, enhance productivity, and reduce material waste, the roll forming machine stands as an essential tool in modern construction practices. As the demand for steel structures continues to rise, so too does the relevance of advanced manufacturing solutions like the CZ purlin roll forming machine, ensuring that the industry can meet evolving needs while maintaining standards of safety and quality.