The steel downpipe roll former making machine is revolutionizing the construction industry by delivering precision, efficiency, and customization capabilities like never before. With the growing demand for high-quality drainage systems in both residential and commercial properties, understanding the significant benefits of these machines can greatly impact your projects.

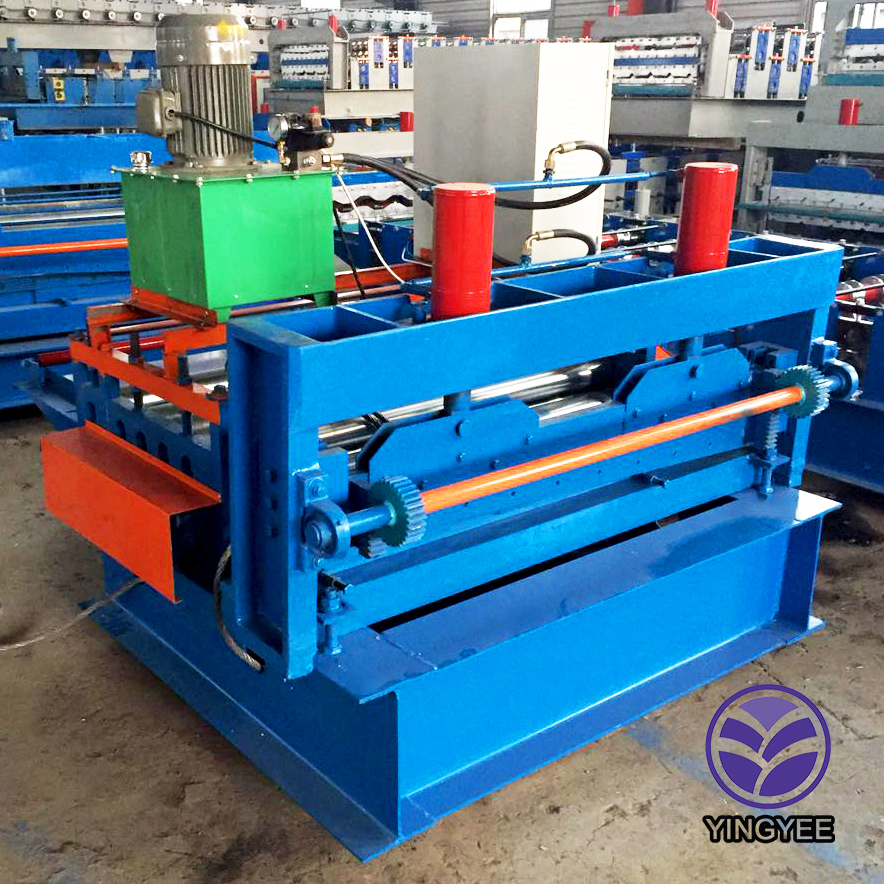

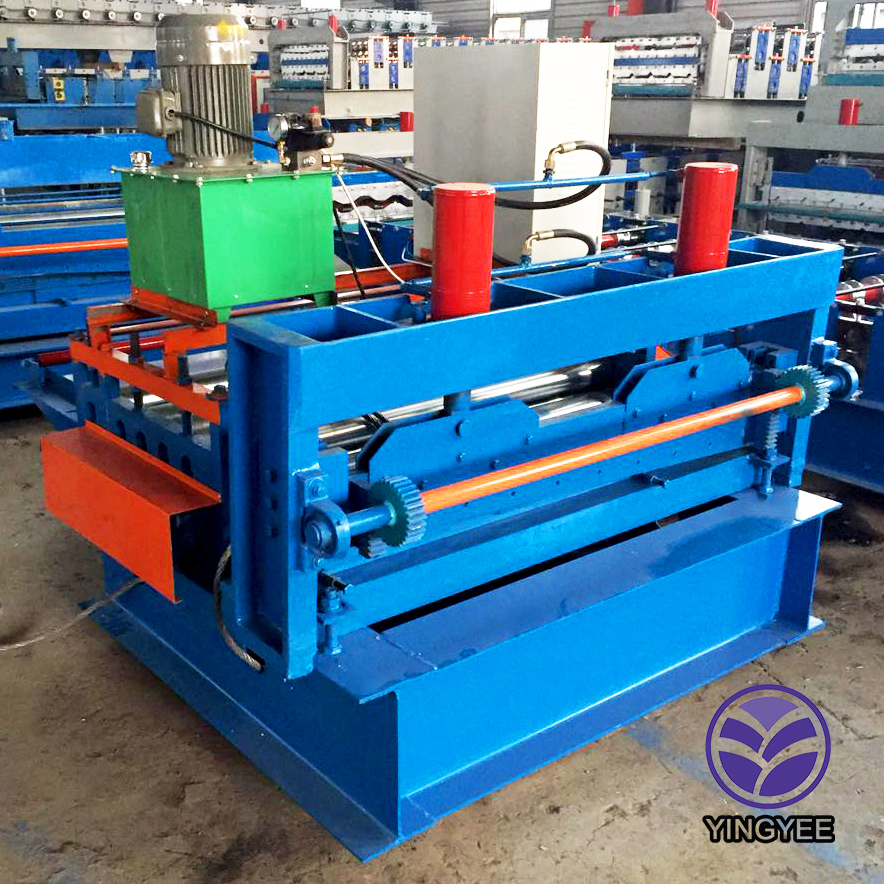

A steel downpipe roll former making machine is a sophisticated piece of equipment designed to shape coiled steel sheets into perfectly contoured downpipes. This specialized machine plays a critical role in ensuring effective water drainage by crafting downpipes that match specific design requirements of modern architectural practices. One of the primary advantages of using such a machine is its ability to produce consistent and precise results regardless of the complexity or size of the project.

The precision offered by these machines is unmatched. Utilizing advanced roll forming technology, these machines ensure that each piece of downpipe is shaped to exact specifications, reducing the risk of errors that could lead to water leakage or inefficient drainage. As a result, construction projects benefit from downpipes that seamlessly integrate into the building's overall design, enhancing both functionality and aesthetics.

Efficiency is another hallmark of the steel downpipe roll former making machine. Traditional methods of downpipe production are often labor-intensive, time-consuming, and prone to human error. In contrast, roll former machines dramatically reduce production time while maintaining high precision. This efficiency not only lowers labor costs but also speeds up the construction timeline, allowing projects to be completed faster and more economically.

steel downpipe roll former making machine

Customization is where these machines truly shine. The construction industry often demands bespoke solutions to meet innovative architectural designs. Having a machine capable of tailoring downpipes to specific requirements allows builders and architects to explore unique designs without compromising on drainage efficiency. This capability not only expands creative possibilities but also ensures that functional needs are met, creating a perfect blend of form and functionality.

Investing in a steel downpipe roll former making machine means having access to cutting-edge technology backed by years of industrial expertise. Manufacturers of these machines are well-versed in the demands of the construction industry, offering solutions that adhere to the highest standards of quality and durability. By leveraging this expertise, stakeholders in the construction sector can benefit from robust and reliable downpipe systems that meet local and international building codes.

Furthermore, the trustworthiness of these machines translates into long-term benefits for both manufacturers and end-users. By choosing a reputable machine, stakeholders are assured of consistent performance, easy maintenance, and access to technical support. This reliability reduces overall costs through minimized downtime and ensures that the final product is one that clients can trust to perform excellently over time.

In conclusion, the steel downpipe roll former making machine is an indispensable tool in the modern construction landscape. Offering unparalleled precision, efficiency, and customization potential, these machines not only expedite the construction process but also ensure high-quality outcomes that adhere to stringent standards. By choosing the right machine, industry professionals can leverage unmatched expertise and trustworthiness, leading to greater success in both residential and commercial construction projects. Embracing this technology is a strategic move that promises enhanced project delivery and client satisfaction.