The Essential Role of Steel Door Frame Making Machines in Modern Manufacturing

In the realm of modern manufacturing, the efficiency and precision of production processes are paramount

. Among the many specialized machines that facilitate construction and assembly, steel door frame making machines stand out as essential tools for producing durable and reliable door frames that form the backbone of many architectural designs.Steel door frames are widely appreciated for their strength, security, and aesthetic appeal. The manufacturing of these frames requires not only high-quality materials but also advanced machinery capable of delivering consistent results. Steel door frame making machines are designed to automate the process, significantly enhancing productivity while ensuring high standards of quality.

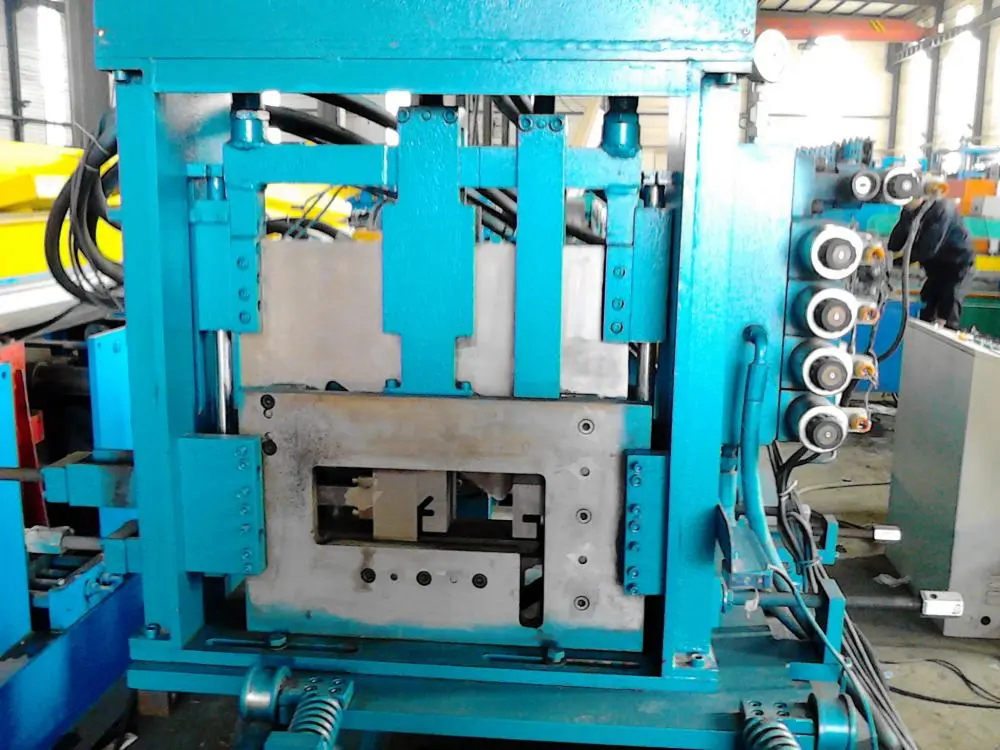

These machines come equipped with various technologies that enable them to perform multiple functions, including cutting, bending, welding, and finishing the steel components. The incorporation of Computer Numerical Control (CNC) technology into these machines allows for precise measurements and cuts, minimizing material waste and improving overall efficiency. The CNC systems can be programmed to accommodate varying specifications, adapting quickly to different designs and requirements.

One of the key advantages of using steel door frame making machines is the speed of production. Automated systems can produce door frames at a much faster rate than manual methods. This acceleration in the production process not only meets market demands but also helps manufacturers reduce labor costs and increase profitability. With a streamlined workflow, businesses can fulfill large orders without compromising on quality.

Additionally, the durability of steel door frames produced using these machines cannot be overstated. Steel is inherently resistant to various environmental factors, including moisture, fire, and pests. Consequently, steel door frames provide enhanced safety and longevity, making them a preferred choice in commercial and residential applications. The precision achieved with modern manufacturing technologies ensures that each frame fits perfectly into its designated opening, thereby enhancing structural integrity.

Moreover, the versatility of these machines allows manufacturers to experiment with different designs and customizations. From traditional to contemporary styles, the ability to produce bespoke frames means that clients can achieve their desired aesthetic without sacrificing performance. This flexibility is crucial in a competitive market where consumer preferences constantly evolve.

In conclusion, steel door frame making machines play a vital role in the manufacturing of high-quality door frames. Their efficiency, precision, and adaptability not only streamline production processes but also contribute to the overall quality and durability of the final product. As the demand for secure and aesthetically pleasing building solutions continues to rise, investing in advanced steel door frame making technology is essential for manufacturers aiming to stay ahead in the industry. Ultimately, these machines are not just tools; they are the driving force behind innovation in construction and design.