The Evolution and Importance of Steel Door Frame Making Machines

In today's fast-paced construction and manufacturing industries, efficiency and quality are paramount. One of the critical components in building a safe and secure infrastructure is the door frame, which serves as a crucial element in the overall design and functionality of a building. Among the various types of door frames, steel door frames have gained significant popularity due to their strength, durability, and security features. This surge in demand has subsequently led to advancements in machinery used for producing steel door frames.

Steel door frame making machines are specialized equipment designed to fabricate door frames efficiently and consistently. These machines utilize various processes, including cutting, welding, and bending, to create high-quality steel frames that meet industry standards. The evolution of these machines reflects broader trends in technology, automation, and manufacturing efficiency.

Advancements in Technology

Modern steel door frame making machines come equipped with advanced technological features that enhance performance and productivity. Many of these machines are now fully automated, allowing for increased production rates with minimal human intervention. Automation reduces the risk of errors and inconsistencies in the final product, ensuring high-quality door frames that comply with technical specifications.

Computer Numerical Control (CNC) technology is a significant advancement in this field. CNC machines can produce door frames with precise measurements and intricate designs, allowing manufacturers to cater to various architectural requirements. The ability to program these machines with different specifications enables flexibility in production, catering to small custom orders or large-scale projects without compromising quality.

Types of Steel Door Frame Making Machines

There are various types of steel door frame making machines, each designed for specific manufacturing processes. Some of the primary types include

1. Cutting Machines These machines are responsible for cutting steel sheets into the required dimensions for door frames. Efficient cutting machines minimize material wastage and enhance overall productivity.

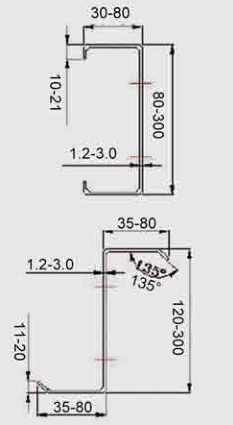

2. Bending Machines After cutting, the steel sections often need to be bent to form the desired shape of the door frame. Bending machines utilize hydraulic or mechanical processes to ensure accurate and uniform bends.

3. Welding Machines Welding is essential for assembling the various components of the door frame. Automated welding machines can perform consistent and durable welds, which are critical for the structural integrity of the frame.

4. Finishing Machines The final step in the manufacturing process involves finishing the door frames for aesthetic appeal and corrosion resistance. This may include painting, powder coating, or galvanizing.

Economic Impact

The production of steel door frames using specialized machines not only meets the growing demand in the construction industry but also contributes positively to the economy. It creates jobs in manufacturing, design, and engineering, and supports various supply chains, from raw materials to logistics. As more builders and architects recognize the benefits of steel door frames, the market for door frame manufacturing continues to expand.

Additionally, the durability of steel door frames leads to lower maintenance costs over time. Buildings constructed with high-quality steel frames provide long-term value to owners and occupants, which is crucial in a competitive real estate market.

Sustainability Considerations

As sustainability becomes an increasingly pressing issue in manufacturing, steel door frame making machines are adapting to meet these challenges. The recyclability of steel makes it an eco-friendly choice for building materials. Modern machines also aim to reduce energy consumption and waste during the manufacturing process.

Innovations such as using energy-efficient motors and incorporating recycling units within the manufacturing lines contribute to a more sustainable production cycle. Manufacturers are becoming more aware of their environmental footprint, and many are implementing practices that prioritize sustainability while maintaining high-quality production standards.

Conclusion

Steel door frame making machines represent a fascinating intersection of technology, engineering, and market demand. Their development has transformed the construction landscape by providing solutions that prioritize speed, efficiency, and quality. As these machines continue to evolve, they will play an essential role in meeting the growing need for robust and reliable building components, ensuring that future structures are not only functional but also safe and sustainable. The investment in advanced machinery will undoubtedly foster a more resilient construction industry, equipped to handle the demands of modern architecture.