The Significance of Steel Deck Cold Bending Machines in Modern Construction

In the ever-evolving world of construction technology, the introduction of specialized machinery has significantly enhanced efficiency and precision in building processes. One such machine that has garnered attention is the steel deck cold bending machine. This innovative equipment plays a critical role in the production of steel decking, a crucial component in the construction industry, particularly in commercial and industrial buildings.

Understanding Steel Decking

Steel decking refers to a series of metal panels that are used as a structural element in buildings, providing a base for concrete slabs and offering significant strength. It is predominantly used in building floors and roofs, making it an essential material for the structural integrity of modern buildings. The demand for steel decking has skyrocketed in recent years due to its advantages, including durability, fire resistance, and speed of installation. However, the key to maximizing these benefits lies in the manufacturing process.

The Role of Cold Bending Machines

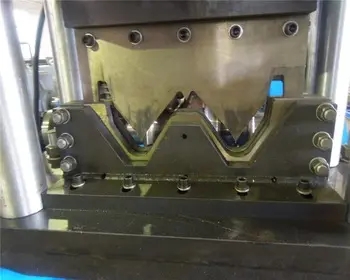

Cold bending machines are specially designed to shape and form steel sheets without the application of heat. This technique is vital because heating materials can alter their properties and may lead to unpredictable results. The cold bending process allows for precise manipulation of metal sheets, resulting in high-quality steel decks with exact specifications.

Cold bending machines utilize advanced technology to ensure consistent quality and efficiency in production

. These machines can bend and form steel into various profiles, which are crucial for creating different types of decking. The ability to produce complex shapes efficiently has made cold bending machines a mainstay in the manufacturing process.Benefits of Using Cold Bending Machines

1. Precision and Accuracy One of the primary advantages of using steel deck cold bending machines is the precision they offer. Automated systems can produce components with incredibly tight tolerances, ensuring that every piece fits perfectly into the overall structure. This precision minimizes waste and reduces the need for costly errors in the field.

2. Increased Production Speed Cold bending machines streamline the manufacturing process, allowing for faster production of steel decking. With the ability to handle high volumes of material rapidly, these machines can meet the demands of large-scale construction projects without compromising quality.

3. Versatility These machines are not only limited to producing standard steel decking profiles; they can also create customized designs tailored to specific project requirements. This versatility enables construction companies to explore innovative designs and solutions, enhancing architectural creativity and functionality.

4. Energy Efficiency The cold bending process consumes less energy than hot forming techniques, making it a more environmentally friendly option. As the construction industry moves towards sustainable practices, the use of energy-efficient machinery is becoming a vital aspect of modern manufacturing.

5. Cost-Effectiveness Investing in a cold bending machine may seem significant at first; however, the long-term savings from reduced material waste, lower labor costs, and increased production capacity can make them a financially sound decision for manufacturers. Additionally, the enhanced quality of the produced steel decks can lead to fewer returns or replacements.

Conclusion

As the construction industry continues to push the boundaries of design and sustainability, steel deck cold bending machines will remain integral to the process. The precision, speed, and efficiency they offer not only contribute to the advancement of building technologies but also support the evolving demands of modern construction projects. The adoption of cold bending technology represents a forward-thinking approach that aligns with contemporary needs for high-quality materials and sustainable practices.

In conclusion, the steel deck cold bending machine exemplifies how innovation in machinery can drive progress in the construction industry. By enhancing production capabilities and facilitating the creation of complex designs, these machines will play a crucial role in shaping the future of construction, ultimately contributing to safer, more efficient, and aesthetically pleasing buildings.