The Advancements and Applications of Steel Deck Cold Bending Machines

In recent years, the construction industry has witnessed a significant transformation driven by technological advancements. One of the pivotal innovations in this arena is the steel deck cold bending machine, a vital tool for shaping and forming steel into various profiles used in construction applications. This article explores the features, benefits, and applications of steel deck cold bending machines, highlighting their crucial role in modern construction.

Understanding Steel Deck Cold Bending Machines

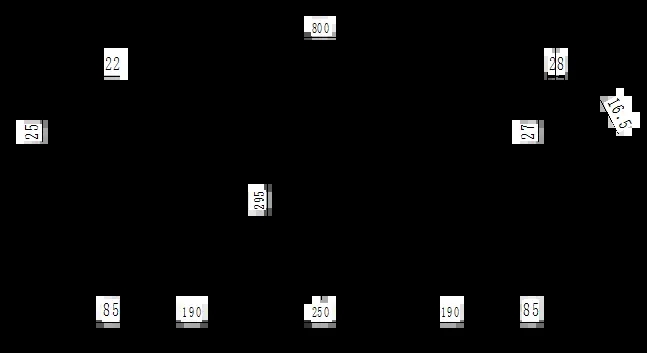

Steel deck cold bending machines are engineered to bend, form, and profile steel sheets through a cold working process, which means that the metal is shaped at room temperature. This methodology enhances the mechanical properties of the material while minimizing deformation. The machines are typically equipped with precision toolsets that allow for consistent and accurate bending, ensuring high-quality output. They can manage a wide range of steel thicknesses and types, making them a versatile choice for various construction tasks.

Key Features of Steel Deck Cold Bending Machines

1. Automation and Precision Modern steel deck cold bending machines often incorporate advanced CNC (Computer Numerical Control) systems. This automation not only ensures high precision in shaping steel but also significantly reduces manual labor and potential errors.

2. Versatility These machines are designed to accommodate multiple profiles and shapes. Whether it's for creating standing seam roofing, floor decking, or wall panels, the adaptability of cold bending machines caters to diverse construction needs.

3. High Efficiency Steel deck cold bending machines are built for speed and efficiency. They can process large volumes of steel in a shorter timeframe, which is crucial for meeting tight deadlines in construction projects.

4. Energy Efficiency Many models are designed with energy-saving mechanisms. They operate with lower energy consumption compared to traditional bending processes, aligning with the industry's push toward sustainability.

5. Ease of Use User-friendly interfaces and controls make these machines accessible to operators with varying levels of experience. This familiarity leads to quicker training times and enhanced productivity on the job site.

Applications in Construction

The applications of steel deck cold bending machines are broad and impactful, transforming the construction landscape in several ways

1. Roofing Systems Steel decks are frequently used in roofing systems due to their strength and durability. Cold bending machines can create intricate profiles that enhance water shedding and resist structural strain.

2. Floor Decking In multi-story buildings, cold-formed steel decking serves as a vital component of composite slabs. The precision with which cold bending machines create these profiles ensures that the floor decks fit perfectly, leading to safer and more secure structures.

3. Wall Panels Cold bending machines are also utilized to manufacture steel wall panels, which provide excellent insulation and protection against external elements. Their lightweight nature reduces the overall load on building structures.

4. Modular Construction The rise of modular construction—where buildings are prefabricated off-site—benefits significantly from the capabilities of cold bending machines. They allow for the quick and accurate production of components that can be assembled easily on-site.

Conclusion

Steel deck cold bending machines have become indispensable in the construction industry, merging efficiency, precision, and versatility. Their ability to produce high-quality steel profiles at a reduced operational cost has made them a preferred choice among contractors and builders. As the demand for advanced construction techniques continues to grow, these machines will undoubtedly play a critical role in shaping the future of infrastructure development. By leveraging the capabilities of steel deck cold bending machines, the construction industry is not only enhancing its productivity but also contributing to the evolution of sustainable building practices. With ongoing technological advancements, we can expect even more innovative solutions that will further revolutionize the way we build.