Steel Deck Cold Bending Machine A Game Changer in Construction

In the realm of modern construction, the demand for cost-effective and efficient methods of building has driven advancements in technology. One such innovation is the steel deck cold bending machine, a pivotal tool that has revolutionized how steel decking is processed and installed. This machine seamlessly blends efficiency, precision, and versatility, significantly enhancing the productivity of construction projects.

Understanding Steel Decking

Steel decking is an essential component of contemporary structural systems, characterized by its strength and lightweight properties. Typically used in floors and roofs, steel decks are advantageous for their ability to support heavy loads while being easy to install. The traditional method of shaping and creating steel decking required hot processing, which was often cumbersome and time-consuming. Cold bending machines have emerged as a solution that addresses these inefficiencies.

The Functionality of Steel Deck Cold Bending Machines

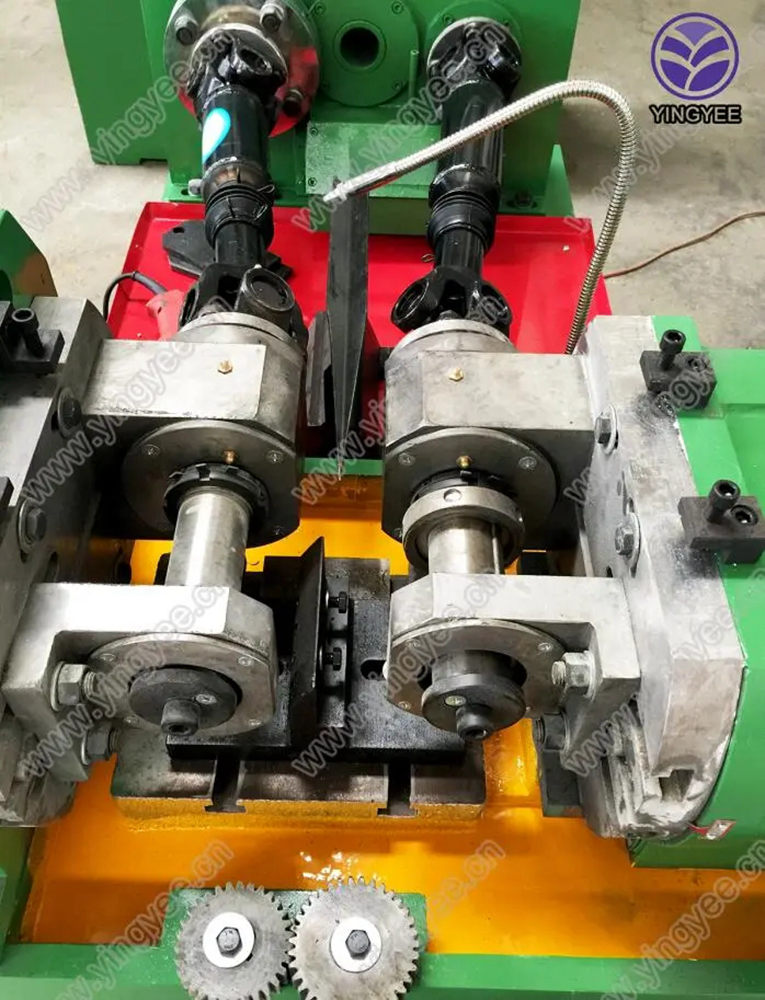

Cold bending machines are designed to shape steel sheets while maintaining their structural integrity and properties. Unlike hot bending—which involves heating steel to a particular temperature—cold bending occurs at room temperature, reducing the risk of weakening the metal. The machines are equipped with specialized rollers and presses that smoothly bend the steel sheets into desired shapes, such as those needed for joists, roof decks, and other structural components.

These machines often feature computerized controls, allowing operators to achieve precise angles and curves with minimal manual input. This high level of automation not only results in uniformity in productions but also reduces the potential for human error. Furthermore, the speed at which these machines operate significantly diminishes production time, making them invaluable in fast-paced construction environments.

Key Advantages of Cold Bending

The benefits of using a steel deck cold bending machine are manifold. First and foremost, the cold bending process enhances safety and reduces the risk of fire hazards associated with hot processes. Additionally, because the steel is not heated, it avoids issues related to warping or distortion that can occur in hot bending.

Another indispensable advantage is the waste reduction. With precise cutting and shaping, these machines optimize the use of raw materials, minimizing scrap metal. This not only leads to cost savings for manufacturers but also promotes a more sustainable approach to construction—a key concern in today’s environmentally conscious society.

The portability of cold bending machines represents another significant enhancement for construction sites. Many of these machines can be designed to be mobile, allowing them to be transported directly to the site where the steel decking is required. This on-site capability reduces the lead times often associated with transporting finished components from factories to projects, further streamlining the construction timeline.

Applications Across Industries

Steel deck cold bending machines find applications across a broad range of sectors, including commercial, residential, and industrial construction. In commercial building projects, they often play a critical role in creating the structural elements that support roofs and floors while enabling architects to realize complex designs.

Additionally, the machinery can be tailored for specific applications, meaning they can accommodate various types of steel decks, including composite and non-composite forms. This versatility means projects can achieve their intended architectural goals without requiring extensive re-engineering of components.

Conclusion

The steel deck cold bending machine stands as a testament to the advancements in construction technology, offering solutions that prioritize efficiency, safety, and precision. As the construction industry moves towards more innovative methods, these machines will undoubtedly play a pivotal role in shaping the skyline of tomorrow. Their ability to streamline production processes and reduce waste aligns perfectly with the ongoing push for sustainability in construction, ensuring that they are not just a temporary trend, but a cornerstone of future building techniques. With continued investment and development, the future looks bright for steel deck cold bending machinery, promising to keep pace with the evolving demands of modern architecture and engineering.