Understanding Steel Coil Cut to Length Lines

In the world of manufacturing and metalworking, the precision and efficiency of processing materials can significantly impact the overall quality of the final product. One essential process in this sector is the handling and cutting of steel coils, where a specific piece of equipment known as a steel coil cut to length line plays a pivotal role. This article examines the functionality, advantages, and applications of steel coil cut to length lines.

What is a Steel Coil Cut to Length Line?

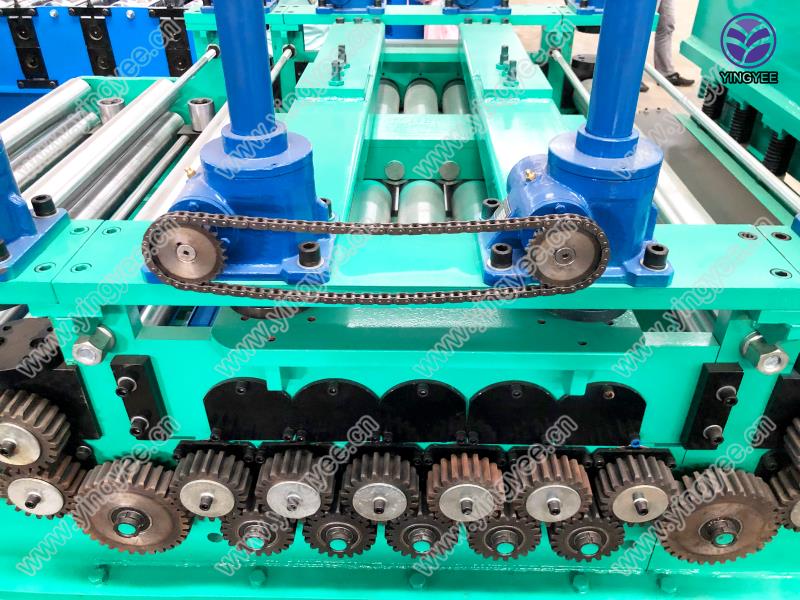

A steel coil cut to length line is an automated system designed to cut large rolls of steel, known as coils, into specific lengths as per the requirements of the manufacturing process. These lines are equipped with various components that facilitate the uncoiling, leveling, and cutting of steel sheets. The process begins with the feeding of the coil into the uncoiler, which unwinds the coil for further processing.

Once the coil is uncoiled, it proceeds to the leveling station, where mechanical rollers flatten the material to eliminate any bends or distortions, ensuring a smooth surface. This leveling is crucial, as it enhances the quality of the final product by preparing the steel for accurate cuts. After leveling, the steel sheets are measured and subsequently cut to the desired lengths using precision cutting tools.

Advantages of Steel Coil Cut to Length Lines

1. Precision Cutting One of the most significant advantages of using a steel coil cut to length line is the precision it offers. These machines are programmed to make accurate cuts, ensuring that the end product meets the exact specifications required by customers. Precision reduces waste and increases the viability of the steel for various applications.

2. Increased Efficiency Automated cut to length lines significantly improve the efficiency of the production process. The entire operation—from uncoiling to cutting—can be executed in a seamless flow, minimizing downtime. This efficiency allows manufacturers to fulfill large orders more quickly and effectively.

3. Versatility Steel coil cut to length lines can handle different types and thicknesses of steel material, making them versatile for various applications. Manufacturers can customize the line settings to accommodate a wide range of products, from thin sheets used in automotive applications to thicker plates suitable for heavy construction.

4. Reduced Labor Costs Automation inherently reduces the need for manual labor in cutting processes. By implementing cut to length lines, companies can save on labor costs while simultaneously reducing the potential for human error. This shift allows workers to focus on higher-value tasks in the production process.

5. Quality Control Many advanced cut to length lines incorporate technology that monitors the cutting process in real time. This integration of quality control systems helps detect any deviations in dimensions or defects in the material, ensuring that only high-quality products reach the market.

Applications of Steel Coil Cut to Length Lines

Steel coil cut to length lines are utilized across various industries, showcasing their flexibility and reliability.

- Automotive Industry In automotive manufacturing, precise dimensions and high-quality metals are critical. Cut to length lines support the production of essential components such as body panels and frames.

- Construction Sector Steel sheets cut to specific lengths are widely used in the construction industry, providing materials for beams, columns, and other vital structures.

- Home Appliances Manufacturers of home appliances often require steel sheets cut to length for parts such as refrigerators, washing machines, and ovens, where precision and durability are paramount.

In conclusion, steel coil cut to length lines are instrumental in modern manufacturing. Their ability to deliver precision, efficiency, and versatility makes them invaluable in various industries. With advancements in technology, these lines continue to evolve, allowing manufacturers to meet the changing demands of the market while maintaining high standards of quality. Investing in such technology can lead to improved production processes, cost savings, and enhanced product quality, firmly establishing these systems as a cornerstone of metal processing.